INSTALLATION AND OPERATION

Figure 2:

TIG Welding Connections

Diameter of

Electrode

(mm)

Diameter of

Nozzle

(mm)

Welding

Current

(A

)

DC

Gas Debit

(lt/min)

1.0

1.6

6.3

9.5

15 - 70

30 - 150

6 - 8

6 - 8

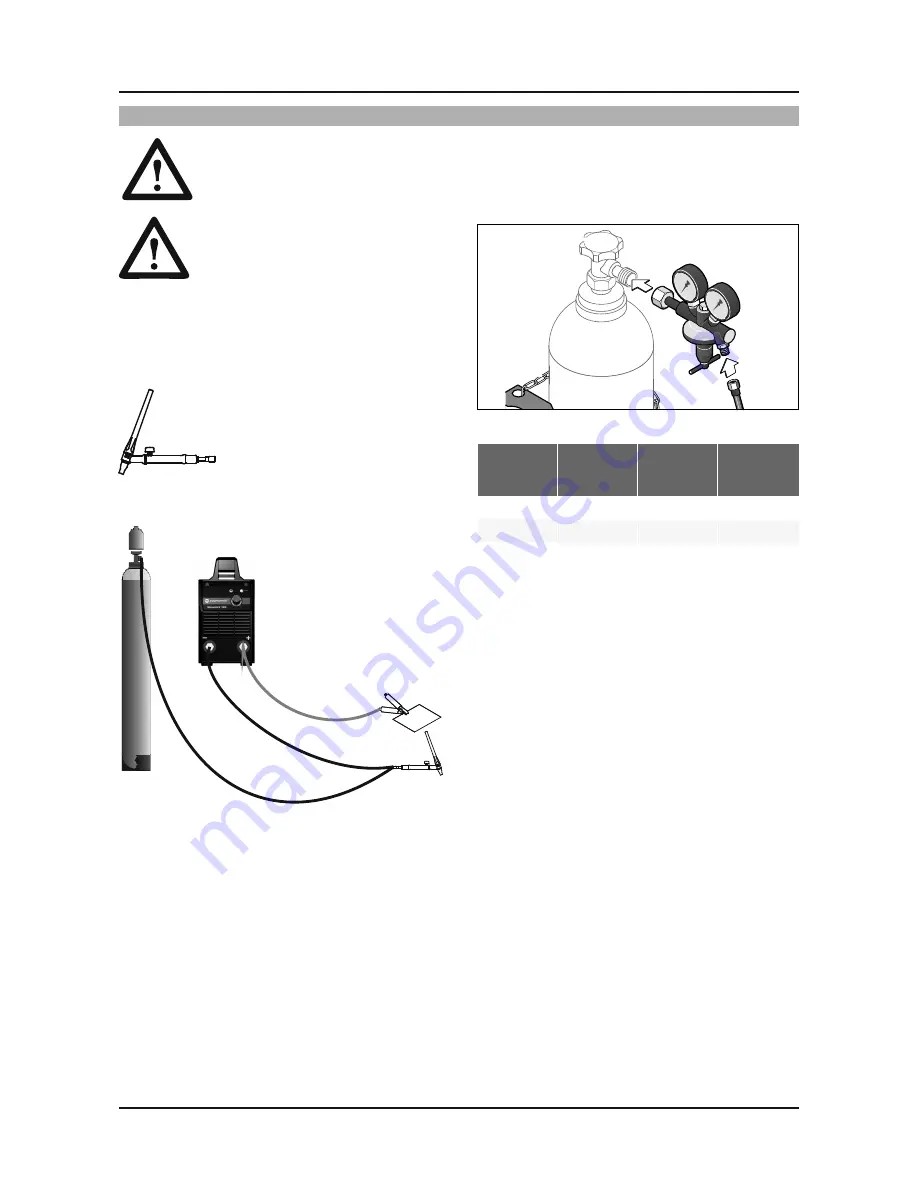

Install the Argon gas regulator onto the Argon gas

cylinder.

C

gas hose of the torch

the

regulator

onnect the

to

gas

.

TIG torch with a valve should be

used.

Connect

TIG orch

to the negative

of

the machine.

the

t

power

cable

welding

socket

and the earth cable to

the positive welding socket

(5)

6

( )

Figure 3:

Connecting Gas Cylinder

2.4 CONNECTIONS FOR TIG WELDING

9

MONOSTICK 160i

Install the Argon gas regulator onto the Argon gas

cylinder.

C

gas hose of the torch

the

regulator

onnect the

to

gas

.

Adjust the desired current and the machine is

ready to weld.

SWITCH ON the machine via power switch

and

check if power LED

lights up and cooler fan

works.

(1)

(2)

While inserting the plug into the

socket, pay attention that main

switch is positioned to “OFF” “0”.

Before plugging your machine to the

electrical line, check if the correct

voltage exists.

AR

Summary of Contents for Monostick 160i

Page 1: ......