3.2 NONPERIODIC MAINTENANCE

Contact tip and nozzle on the torch have to be cleaned regularly and

changed if required. Contact tips must be in good condition, longer tips

generally give better results.

NOTE:

The above recommended maintenence periods are indicative, these may vary according to the

work shop conditions.

3.3 TROUBLESHOOTING

If the Thermal Protection LED

lights up while cooling fan is working and the machine doesn't weld; machine

maybe overheated and stopped for auto protection due to overheat. Hot weather or working in high current

values for long time may cause this. Let the machine on for a while in order to cool down itself with the cooling

fan. After it cools enough, Thermal Protection LED

fades away and the machine can weld.

When the Power LED

is lighting, cooling fan is working but the machine does not weld; turn off the machine

for 1 minute then turn it on again and try to weld. If it still doesn't weld,

(3)

(3)

(2)

contact to your authorized technical

service.

3. MAINTENANCE AND TROUBLESHOOTING

MAINTENANCE AND TROUBLESHOOTING

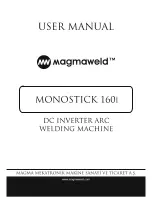

3.1 PERIODIC MAINTENANCE

Clean the labels on the

machine, replace the worn

out labels.

Repair or replace the worn

out welding cables.

ONCE IN EVERY 3 MONTHS

ONCE IN EVERY 6 MONTHS

Open the covers of the

machine and clean with

dry air.

Clean and tighten the weld

terminals.

Check isolation of the

electrode holder,

and their cables.

earth

clamp

OR

10

MONOSTICK 160i

Strictly follow the instructions contained in safety rules while servicing the

machine.

Before removing any screw on the machine for maintenance, power

supply must be disconnected from the electric lines and enough time

should be allowed for capacitor discharging.

Summary of Contents for Monostick 160i

Page 1: ......