4

MONOSTICK 160i

SAFETY RULES

NOISE CAN DAMAGE HEARING

Noise from certain industrial processes or equipments can damage hearing.

Wear approved ear protection if noise level is high.

WORKING IN SMALL AND CONFINED PLACES CAN BE DANGEROUS

While welding and cutting in small, confined places, always have a trained watchperson nearby

Avoid working in such confined places

.

.

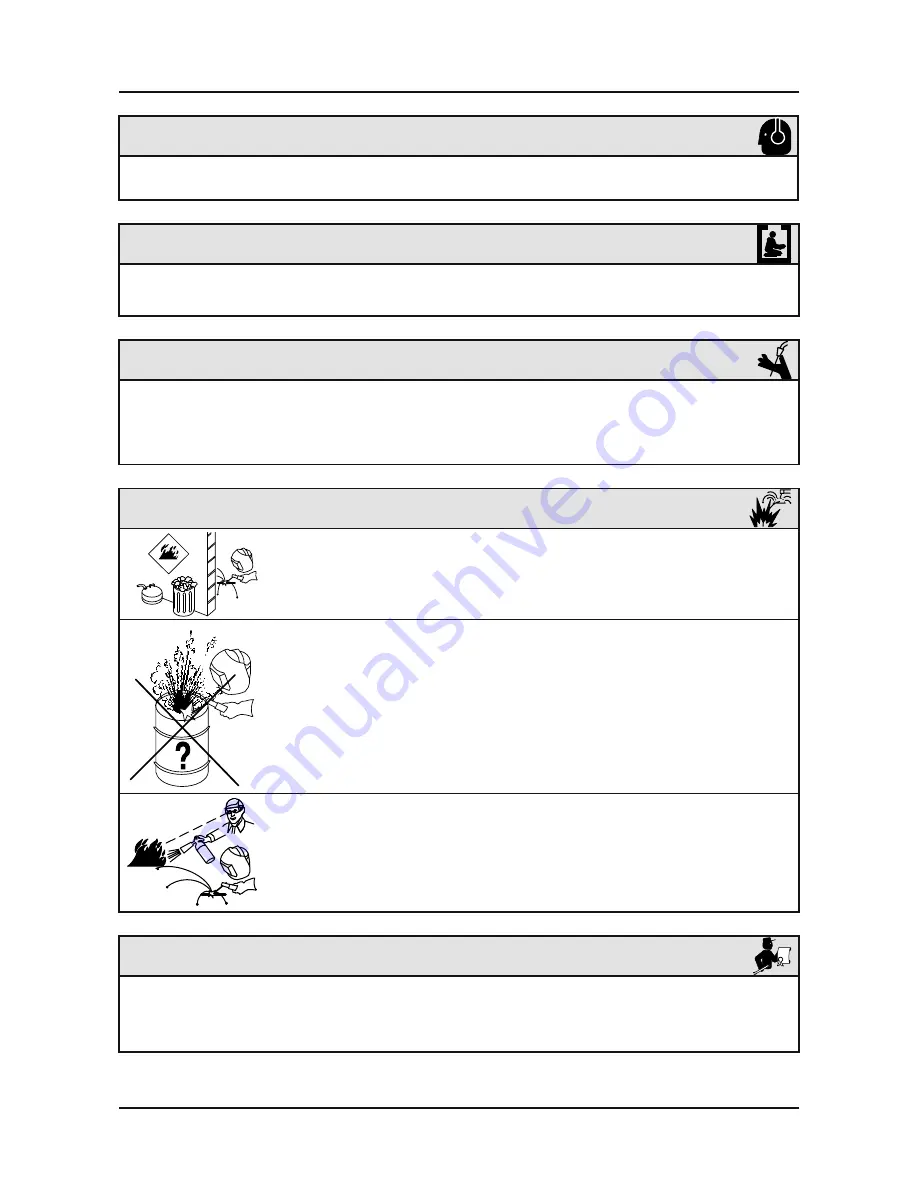

WELDING CAN CAUSE FIRE OR EXPLOSION

Never weld near flammable material. It may cause fire or explosions.

Before starting to weld, move flammables away or protect them with flame-proof

covers.

Do not weld on and cut closed tubes or pipes

Before welding on closed containers, open and clear them entirely. Welding

operations on these parts must be performed with the utmost caution

Never weld containers or pipes containing or which have contained substances

that could give rise to explosions

.

.

.

Welding equipments warms up so never position them on flammable surfaces.

Welding sparks can cause fire. For that reason, keep extinguishing means, such as

fire extinguishers, water and sand

easy

reach

security valves, regulators and other valves

on flammable, explosive

and compressed gas circuits in good condition

which are

to

.

Keep

, used

,

.

WELDING WIRE MAY CAUSE INJURY

Do not point the torch toward any part of a human body, other persons or any type of metal when unwinding

welding wire

While extracting the wire from the spool by hand, it may spring suddenly and injure you or a nearby person,

protect especially your eyes and face.

.

MAINTENANCE MADE BY UNQUALIFIED PERSONS MAY CAUSE INJURIES

Electrical devices should not be repaired by unqualified persons. Improper repairs can cause serious

injuries or even death during applications

The components of the gas circuit works under pressure. The service given by unqualified persons may

cause explosions and operators can be injured seriously

.

.

Summary of Contents for Monostick 160i

Page 1: ......