TECHNICAL INFORMATION

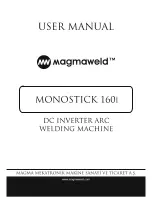

1.3 DATA PLATE

Manual Metal Arc Welding

Direct Current

Descending Characteristics

Line Input-1 Phase Alternating Current

Appropriate To Operate In Dangerous Work Area

X

:Duty Cycle*

U

:Open Circuit Voltage

U

:Line Voltage and Frequency

U

:Rated Welding Voltage

I

:Input Current

I

:Rated Welding Current

IP23S

:Protection Class

0

1

2

1

2

S

:Input Power

1

Single Phase Static Frequency Converter

Transformer Rectifier

1.4 TECHNICAL SPECIFICATIONS

1.5 ACCESORRIES

STANDARD ACCESORRIES

PIECE

PRODUCT CODE

A390000200

K301100203

1

1

Electrode Holder and Cable (200A)

Earth Clamp and Cable (16mm² - 3mt)

VALUE

UNIT

TECHNICAL SPECIFICATIONS

Line Voltage (Single Phase)

Input Power

Input Current

Open Circuit Voltage

Welding Current Range

Rated Welding Current

Protection Class

(%

)

Rated

(%

)

(%

)

( x x )

25

25

Power Factor

25

Fuse

Cooling Method

Dimensions L W H

Weight

Standarts and Approvals

V

kVA

A

V

A

A

A

mm

kg

DC

DC

DC

2 0

3

7,2

31,5

0,97

75

10 - 160

150

32 - Delayed

IP23S

Air

160x312x405

7,8

CE, EN60974-1, EN60974-10

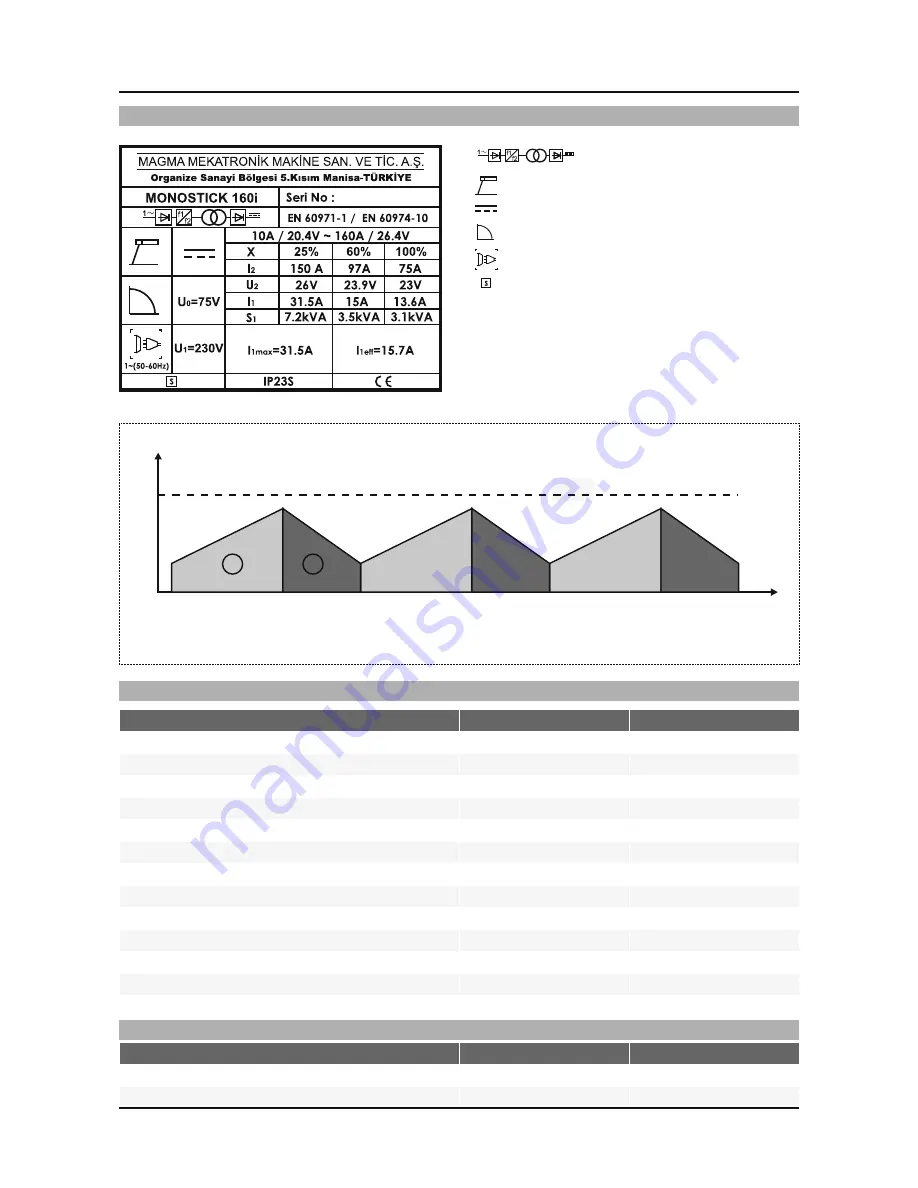

*Duty Cycle

1

2

Temperature ( C)

°

Time (min.)

6 min.

6 min.

6 min.

4 min.

4 min.

4 min.

Duty cycle defines the percentage of welding time out of a period of 10 minutes at a given current and ambient

temperature (standard is 40°C). For example, a welder with 60% duty cycle must be rested (2) for 4 minutes,

after 6 minutes of continuous welding (1).

7

MONOSTICK 160i

Summary of Contents for Monostick 160i

Page 1: ......