EN

27

monoTIG 165ip / monoTIG 200ip

www.magmaweld.com

USER MANUAL

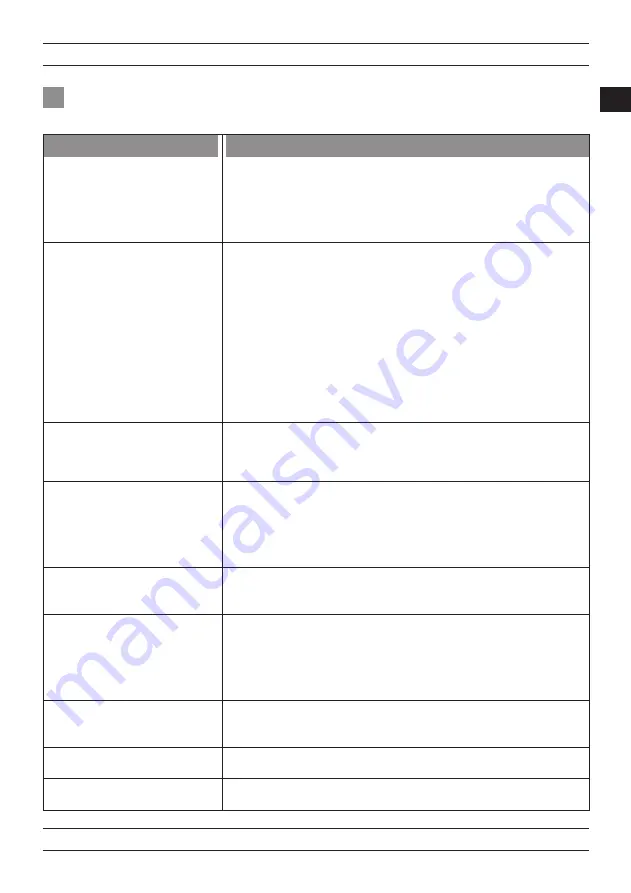

4.2 Troubleshooting

The following tables contain possible errors to be encountered and their solutions.

The machine will not turn on

Machine does not weld/does poor

welding

Tungsten melts or the nozzle

breaks

Bubbling or blackening is observed

in TIG welding

HF (High Frequency) occurs but

welding is difficult to start

HF (High Frequency) occurs, does

not start welding

HF (High Frequency) does not start

There is a liquid leak in the

water cooling unit

There is no liquid flow in

the water cooling unit

• Make sure there is power connected to the machine

• Check whether the mains connections are correct

• Check the power supply fuses, mains cable and plug

• Check the on/off switch

• If you have completed all the checks and the problem still persists, contact

the authorized service

• Make sure that the grounding clamps of the machine is connected to the

workpiece

• Make sure that the cables are secure and that the connection points are

not worn

• Make sure that the parameter and process selection are correct

Follow the steps below according to the process you have selected

• Check the pole that the electrode must be connected to and the current

value that must be set on the machine

• Check that the gas flow is open, ensuring that the flow is correct

• Make sure that the tungsten tip is clean

• Make sure the welding torch is secure

• If you have completed all the checks and the problem still persists, contact

the authorized service

• Check that the TIG torch (-) is connected to the pole. Connect if the torch is

not connected to the (-) pole

• If you have completed all the checks and the problem still persists, contact

the authorized service

• Check the gas flow rate from the tip of the torch with a flow meter

• If the surface of the welded workpiece is dirty, clean the surface of the piece

• Make sure you use the correct welding gas

• Make sure you select the correct tungsten electrode

• If you have completed all the checks and the problem still persists, contact

the authorized service

• Check the initial current. Increase the initial current if it is too low

• If you have completed all the checks and the problem still persists, contact

the authorized service

• Check that the TIG torch is connected to the (-) pole. Connect if the torch is

not connected to the (-) pole

• Check whether the grounding clamps of the machine is connected to the

workpiece

• If you have completed all the checks and the problem still persists, contact

the authorized service

• Check the pre-gas time. Reduce the pre-gas time if it is too high

• If you have completed all the checks and the problem still persists, contact

the authorized service

• Contact the authorized service

• Contact the authorized service

Error

Solution

Maintenance and Service

Summary of Contents for monoTIG 165ip

Page 32: ...EN 32 monoTIG 165ip monoTIG 200ip www magmaweld com USER MANUAL Circuit Diagram Annex...

Page 34: ......

Page 66: ......

Page 68: ...RU 68 monoTIG 165ip monoTIG 200ip www magmaweld com...

Page 69: ...RU 69 monoTIG 165ip monoTIG 200ip www magmaweld com MIG CV MMA VRD AED...

Page 70: ...RU 70 monoTIG 165ip monoTIG 200ip www magmaweld com n...

Page 71: ...RU 71 monoTIG 165ip monoTIG 200ip www magmaweld com...

Page 72: ...RU 72 monoTIG 165ip monoTIG 200ip www magmaweld com 10 2 TS EN 55011 100 IEC61000 3 12...

Page 73: ...RU 73 monoTIG 165ip monoTIG 200ip www magmaweld com 5 2 IEC 60974 9 a b c d e f g h 60974 9...

Page 74: ...RU 74 monoTIG 165ip monoTIG 200ip www magmaweld com IMF www magmaweld ru wr...

Page 78: ...RU 78 monoTIG 165ip monoTIG 200ip www magmaweld com 2 1 2 2 30 40 C IEC 61000 3 12...

Page 87: ...RU 87 monoTIG 165ip monoTIG 200ip www magmaweld com 6 TIG TIG 5 TIG 10 10 0 9 A U 7 8...

Page 90: ...RU 90 monoTIG 165ip monoTIG 200ip www magmaweld com 10 4 1 TIG 6...

Page 91: ...RU 91 monoTIG 165ip monoTIG 200ip www magmaweld com 4 2 TIG...

Page 92: ...RU 92 monoTIG 165ip monoTIG 200ip www magmaweld com TIG HF HF HF TIG...

Page 93: ...RU 93 monoTIG 165ip monoTIG 200ip www magmaweld com 4 3 E01 E02 E03 E04 E05 E07 E08 E09 E06...

Page 95: ...RU 95 monoTIG 165ip monoTIG 200ip www magmaweld com E27 E29 E30 E26 E28 E31...

Page 97: ...RU 97 monoTIG 165ip monoTIG 200ip www magmaweld com 5 2 L N IGBT...

Page 98: ...RU 98 monoTIG 165ip monoTIG 200ip www magmaweld com 1...

Page 100: ......

Page 129: ...129 TR monoTIG 165ip monoTIG 200ip www magmaweld com KULLANIM KILAVUZU Devre emas Ekler...

Page 130: ......

Page 132: ......