Magna-Matic Corporation - W4599 County Road IW - Waldo WI 53093 USA - Phone: (920) 564-2366 - FAX: (920) 564-2368 - Toll Free USA & Canada

1-800-328-1110

http://

www.magna-matic.com

- email: sales@magna-matic.com © Copyright 2023 All rights reserved

Quick Setup Guide

WARNING

WHEN USING ELECTRIC TOOLS, BASIC SAFETY

PRECAUTIONS SHOULD ALWAYS BE FOLLOWED

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, AND PERSONAL INJURY.

CAUTION

TURN OFF AND UNPLUG

BEFORE SERVICING

Page 1

For all MAG-8200 Series Lawn Mower Blade Sharpeners

Unpack the machine and check components:

Box Contents: Sharpener, Grit Guard, Spanner Wrench, and Arbor Wrench

Assemble the grit guard.

1. Use ten self-tapping screws.

2. Assemble the grit guard sides to the top of the grit guard.

3. The grit guard sides are identical and the holes will only line up in one orientation. (top

vs bottom)

4. Then attach the bottom of the grit guard.

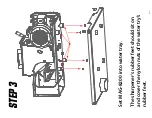

Assemble the grit guard to the MAG-8200

5. Remove the front cover (black cover with model decal on it) to expose the grinding

wheel as shown in images

6. Use two self tapping screws to connect the bottom of the grit guard to the black base of

the sharpener. The bottom of the grit guard is under the base of the sharpener, the put

the screws in from under the machine, see image to right.

7. Use two button head screws with nylon nuts to connect the top of the grit guard to the

red body.

8. Connect the crank handle to the end of the threaded adjustment rod with the set screw

in the crank handle base.

Purchase grinding wheels and other parts

and accessories at:

www.magna-matic.com

If you have any problems or

questions please call:

800-328-1110

For full instruction manual:

www.magna-matic-direct.com/instruction-manuals/

Be sure the MAG-8200 power cord is unplugged. Using

a 5/16” socket wrench remove the (3) screws of the

front steel guard. Locate your spanner wrench and

arbor wrench (both supplied by Magna-Matic.) The

arbor wrench fits into a square notch in the arbor behind

the grinding wheel, and the spanner wrench fits into the

two holes in the arbor nut. See diagrams below.

Always inspect grinding wheels for possible damage

- never mount a cracked grinding wheel.

DO NOT

OVER-TIGHTEN ARBOR NUT - ONLY LIGHT

PRESSURE TO TIGHTEN.

The motor will tighten

the arbor nut every time the sharpener is turned on.

For optimum performance use only grinding wheels

specified by Magna-Matic. All NORTON® brand grind

-

ing wheels sold by Magna-Matic are speed tested for

5500 RPM

NOTE: ARBOR HAS LEFT-HANDED THREADS.

MAG-8200 OEM WHEEL = 9000-35