peening

process creates not only a mating inside

surface on each Idler, but also rolls a wider

extended

edge

around

each

Idler’s

circumference. In addition, the Idler surfaces are

“work hardened” by being

peened

against the

harder Track Chain.

The #1218 Track idler are equipped with two

internal oilite bushings. As these bushings wear

the idler will become loose on the axle. These

bushings can be replaced to extend the life of the

idler.

The 4.5” diameter flanges of the #1218 idlers will

continue to wear over time. Individual idlers

should be replaced when track chains begin

wearing into the tube connecting the flanges.

TRACK SHOES

Your Crawler comes from the factory without

any Track Shoes being installed. You can safely

run your Crawler without Track Shoes, but under

average soil conditions you will be able to attain

only about 70% of your Crawler’s tractive ability.

To gain more traction, you can add the TSO40

GROUSER SHOE KIT

or T S O 4 5 P N O N -

MARKING SHOE KIT. Under average soil

conditions, the addition of Non-Marking Shoes to

your Track will increase traction to approximately

80% of your Crawler’s tractive ability.

Adding

Grouser Shoes will give you the greatest tractive

ability your Crawler can deliver.

GROUSER SHOE INSTALLATION

Grouser Shoes are applied to the top outside

face of each Track Plate and held in position with

3/8x1” Carriage Bolts and 3/8” Flange Lock Nuts.

NOTE

: The Carriage Bolts are inserted into

the 3/8” square holes in top outside face of each

Grouser Shoe and the 3/8” Flange Lock Nut is

applied to the protruding end of each Carriage

Bolt on lower inside face of each mating Track

Plate.

NON-MARKING SHOE INSTALLATION

See instructions for optional TSO45P Non-

Marking Shoes.

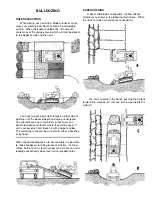

BELT TENSIONING &

REPLACEMENT PROCEDURE

The #1361 Belt drives the MH7000’s attachment

pump. Over time the belt will wear and/or

stretch, which will result in decreased power to

the attachments and/or a squealing noise under

high loads to the attachments. The belt should

be inspected and adjusted/replaced upon such

behavior. The belt should be regularly inspected

according to the service guidelines in this

manual.

µ

Consult the part photos and drawings at

the back of tractor manual to assist in

this procedure.

To inspect / replace the belt:

1) S h u t o ff tractor, apply parking brake, lower

attachments to ground, and remove key.

2) Remove the #1380 Grill. Remove the #1383

Cover by removing the two bolts securing it

to the #1382 Pump Mount.

NOTE

: Spacer tubes are located over these two

bolts between the #1383 Cover, and

#1382 Pump Mount. Take care to not

lose these spacer tubes during removal.

4) Loosen, but not remove, the four bolts

securing the #1382 Pump Mount to the

Engine.

5) To replace the belt. Slide the #1382 Pump

mount to the left until belt tension is relieved

1383