OPERATING WITH FLOAT CONTROL

During hard surface operation, place the control lever

in “float” (held by the detent), and keep the bucket level.

This will permit the bucket to “Float” on the contour of the

working surface. If hydraulic down pressure is exerted,

the bucket will wear faster than normal.

The ‘float” position will prevent the mixing of surface

material with stockpile material. It will also reduce the

chance of surface gouging when removing snow or other

material.

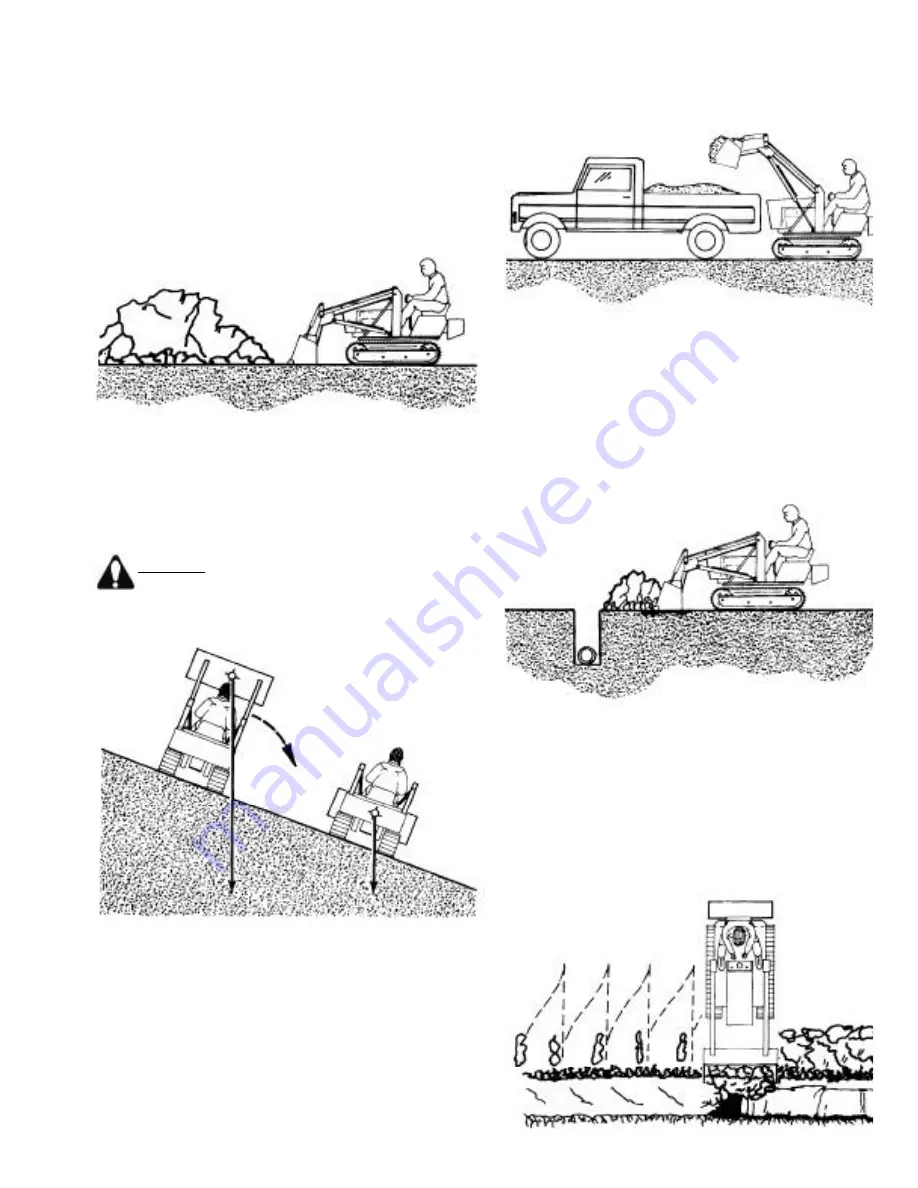

CARRYING THE LOAD

Position the bucket in the full roll back position and

the lift arms as low as possible for maximum stability and

visibility whether the bucket is loaded or empty.

CAUTION: When operating on a hill or slope, keep

the bucket as low as possible. This keeps the

bucket center of gravity (C/G) as low as possible,

giving maximum stability.

When transporting the load, keep the bucket as low

as possible to resist tipping, in case a track drops in a rut.

DUMPING THE BUCKET

Lift the bucket high enough to clear the side of the

vehicle. Move unit in as close to the side of the vehicle

as possible, then dump the bucket.

After the bucket is dumped, back away from the

vehicle while lowering and leveling the bucket.

BACKFILLING

Efficient backfilling occurs by pushing maximum

amounts of soil without losing speed or “stalling.” If a

“stall” occurs, downshift or reduce the depth. If the unit is

not working at capacity in the gear selected, increase the

depth of the cut.

Approach the pile with a level bucket. When

adjusting the depth of cut to a load that can be handled

without going into a “stall,” actuate the control lever for lift

and bucket action simultaneously, or separately as

required, to maintain a level bucket.

Leave the soil in the bucket, as dumping on each

pass is time consuming. Lift and level the bucket for the

next pass while backing from the excavation.

Operate at right angles to the ditch.