coolant levels with an open flame.

•

Never use an open flame to look for leaks

anywhere on the equipment.

•

Never use an open flame as light anywhere on

or around the equipment.

•

When

preparing

Engine

for

storage,

remember that inhibitor is volatile and

therefore dangerous. Seal and tape openings

after adding the inhibitor. Keep container

tightly closed when not in use.

•

Inspect electrical wiring for worn or frayed

insulation. Install new wiring if wires are

damaged.

•

Temperature

in

Engine

and

cooling

compartments may go up immediately after

you stop the Engine.

Be on guard for fires.

•

Before you clean trash from the Engine

compartment, wait until the Engine has

cooled. Open Side Panels to cool the Engine

faster. While the Engine cools, clean trash

from other areas.

•

Check for leaking fuel lines, hydraulic lines,

hoses, or fittings with a piece of cardboard or

wood. Do not use your hands. Tighten loose

fittings. If lines are bent or hoses kinked,

install new parts.

PROTECT AGAINST NOISE

Prolonged exposure to loud noise can cause

impairment or loss of hearing. Wear a suitable

hearing protective device such as earmuffs or

earplugs to protect against objectionable or

uncomfortable loud noise.

AVOID HIGH-PRESSURE FLUIDS

Escaping fluid under pressure can penetrate

the skin causing serious injury. Relieve pressure

before disconnecting hydraulic or other lines.

Tighten all connections before applying pressure.

Keep hands and body away from pinholes and

nozzles which eject fluids under high pressure.

Use a piece of cardboard or paper to search for

leaks. Do not use your hand.

If ANY fluid is injected into the skin, it must be

surgically removed within a few hours by a doctor

familiar with this type of injury or gangrene may

result.

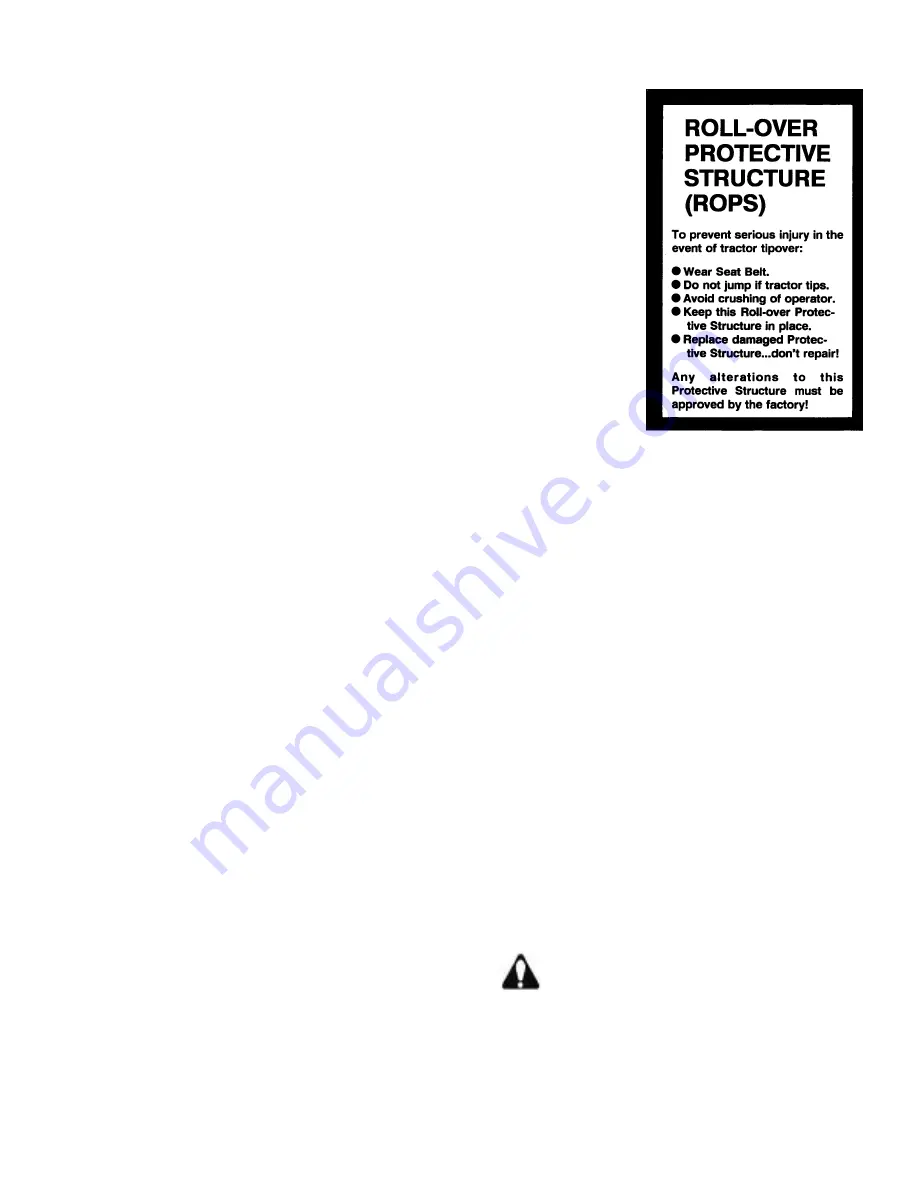

I N S TA L L AND MAINTAIN ROPS

PROPERLY

If

Roll-Over

P r o t e c t i v e

Equipment

is

loosened

or

removed for any

reason,

make

certain all parts

are

reinstalled

correctly. Tighten

mounting bolts to

proper

torque.

The

protection

offered by ROPS

will be impaired if

the

ROPS

is

subject

to

s t r u c t u r a l

damage, has been involved in an overturn

incident or is in anyway altered. Damaged ROPS

should be replaced, not reused.

•

DO

use your Seat Belt if your Crawler has a

Roll-Over Protective Structure (ROPS).

•

DO NOT

use a Seat Belt if your Crawler does

not have a ROPS.

START ENGINE ONLY FROM THE

OPERATOR’S SEAT!

•

Avoid possible injury or death from Crawler

runaway.

•

Do not start Engine by shorting across starter

solenoid terminals. Crawler may start and

move if normal circuitry is bypassed.

•

Never

start Engine while standing on ground.

Start Engine only from operator’s seat, with

Parking Brake engaged.

•

Inspect your Crawler carefully each day

before you start it. See “Pre-Start Inspection”.

•

Clean your Crawler regularly.

WA R N I N G

: The Seat Assembly is

equipped with an electrical safety switch to

prevent starting and operating the crawler while

not occupying the seat. Disabling this feature

creates the potential for severe injury or death.

See Chapter 7 - Service for test procedures to

verify it is operating properly.