Bar, the #441 Brake Switch should be

open

(the

#440 Leaf Spring would have rotated up and

away); the light of the continuity tester should now

be

off

!

If

both

of the above conditions are not met,

you must adjust the height of the #441 Switch.

The Switch is secured top and bottom of the

#538 Bracket with large hex nuts. Raise or lower

the Switch’s height to meet requirements (

A

) and

(

B

) in Brake Switch Test (above) by relocating

these hex nuts. When adjustment is completed,

tighten both hex nuts...terminals of Switch should

point directly to the right. Remove continuity

tester and replace electrical plug on terminals of

Switch. Replace Left and Right Side Panels.

At this time, following recommended safe

starting procedures, start the Engine and check

Switch’s setting...readjust if necessary.

SAFETY CIRCUIT TEST

The Safety Circuit is an electronic method to

sense

safe starting

and

safe operating

conditions. The Circuit performs its

safe start

function by sensing the condition of the Seat

Switch, Brake Switch, and optional Hydraulic

Circuit. The Brake and Hydraulic circuit switches

must be closed in order for the engine to crank.

The seat switch must be closed in order for the

engine to turn over and run.

The

safe stop

function is accomplished by

sensing the condition of the Seat Switch. Once

the Engine is started, the operator must remain

seated thereby keeping the Seat Switch

closed

or

the Engine will shut down.

An added safety feature is its

closed to

operate

function which ensures that the Crawler

will not function if the switch leads are broken or

become disconnected.

TESTING SAFETY CIRCUIT

Conduct the following tests to check proper

functioning of Safety Circuit & related switches:

A

. Following recommended safe starting

procedures, and with operator seated but Parking

Brake not applied, attempt to start Engine. The

Engine should not start. If it does, readjust #441

Switch on #538 Bracket; Switch is mounted too

high in its Bracket and is closing too soon. If

readjustment doesn’t solve the problem, test #441

Switch and replace if necessary.

B

. Following recommended safe starting

procedures, and with Parking Brake

locked

but

with operator standing in the operator’s

compartment (not seated), attempt to start the

Engine. The Engine should not start. If it does,

readjust #441 Switch on #503A Mount; it’s

mounted too

high

in its Mount and is

closing

too

soon. If readjustment doesn’t solve the problem,

test #441 Switch and replace if necessary. Check

“expanded” height of #506 Springs (see below).

C. Following recommended safe starting

procedures, and with Parking Brake

locked

and

operator properly seated, attempt to start Engine.

The Engine should start. If it doesn’t, recheck

settings of #441 Switches in Tests (

A

) and (

B

)

above. Replace Module if necessary.

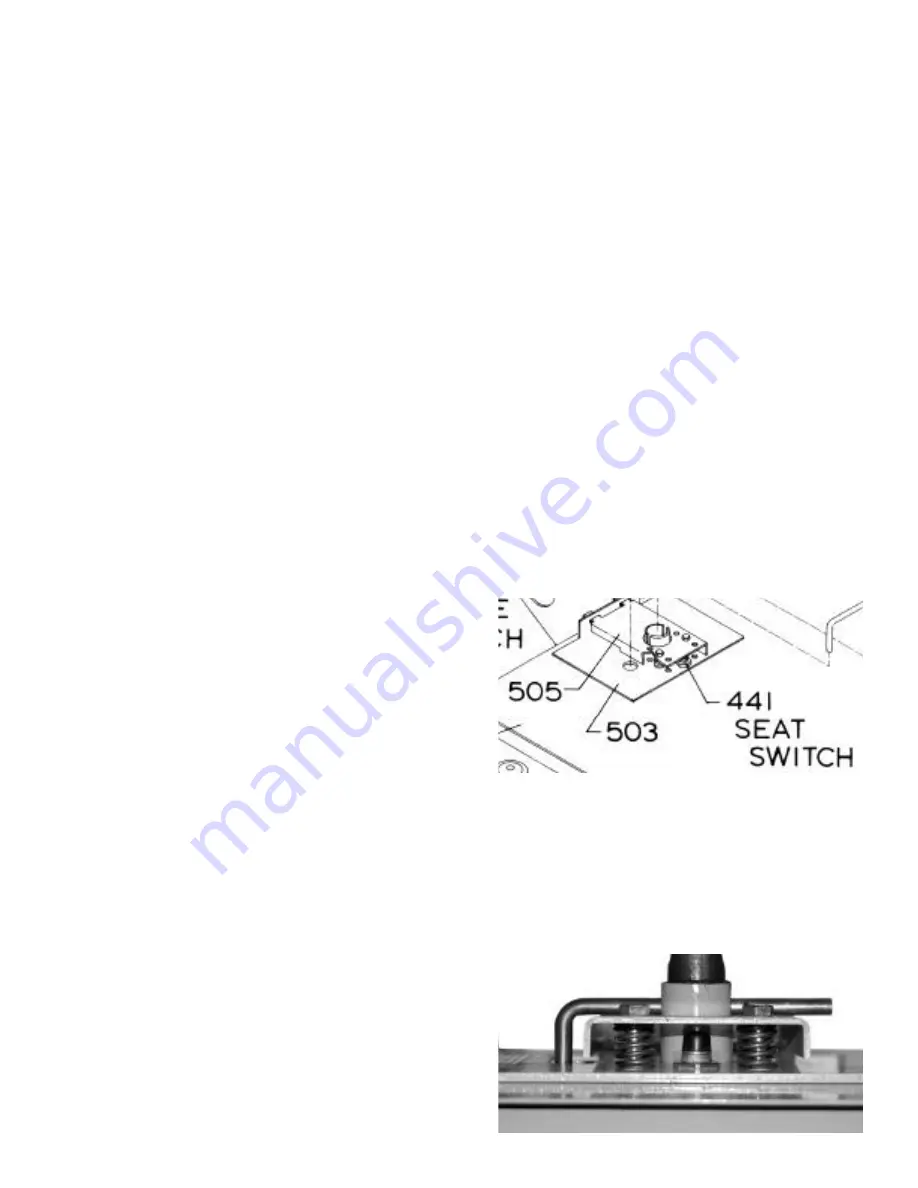

SEAT WEIGHT ADJUSTMENT

The weight of the operator required to activate

the #441 Seat Switch can be adjusted by moving

the pair of #506 Springs back and forth in the

three sets of mating 3/8” holes located between

#503A Mount and #505 Treadle.

The drawing above shows them installed in

the “mid-weight” range. Use the set of holes

forward for the lighter operator; use the set of

holes rearward for the heavier operator.

NOTE

: When reassembling the #506 Springs

to a new position, tighten each 3/8” Cap Screw

such that it will allow each Spring to expand to

only 1” high (measure Spring length only).