Shims until the #1090 Drive Chain is tight...you

may lightly

tap in

the last shims but do not

drive

them in (that would indicate you are over-

tensioning the Chain).

NOTE

: Add the same number of Shims on

each end of #214 Rear Axle to make sure the

Rear Axle will stay horizontal. Replace Cotter

pins removed above and secure them. Tighten

both 1/2” Cap Screws that secure each #231 Axle

Support. This tightening step will draw the Shim

packs

tight and create the proper slack in the

#537 Drive Chain.

REMEMBER to make this #1090 Drive

Chain Adjustment to both sides of Crawler!

Using original bolts, replace the #1212R &

#1212L Guards and tighten.

Follow Track Tensioning procedure in this

manual and re-tension both Tracks. Remove

Crawler from blocks and test run. Check Drive

Chain adjustment and readjust if necessary.

PARKING/EMERGENCY BRAKE

The Parking/Emergency Brake provides a

force approximately equal to the strength of the

Crawler’s drive system and is used in a number of

ways. One way, is as a Parking Brake. In this

capacity, it holds the Crawler in position when the

Engine and drive system is shut off.

In addition, it provides a

safe start mode

, as

the Brake must be engaged before starting the

Engine. If the operator inadvertently touches the

Track Drive Controls during Engine starting, the

Brake will severely load the drive system and

potentially kill the Engine (unless the Track Drive

Controls are released immediately).

The Brake’s other use is that of an Emergency

Brake. If you should ever lose Engine or drive

system power, the Brake can be activated

instantly to hold the Crawler safely in position.

DISK BRAKE ADJUSTMENT

CAUTION

: Read the following Disk Brake

and Disk Puck instructions in their entirety

before

attempting

any

Disk

Brake

adjustments!

µ

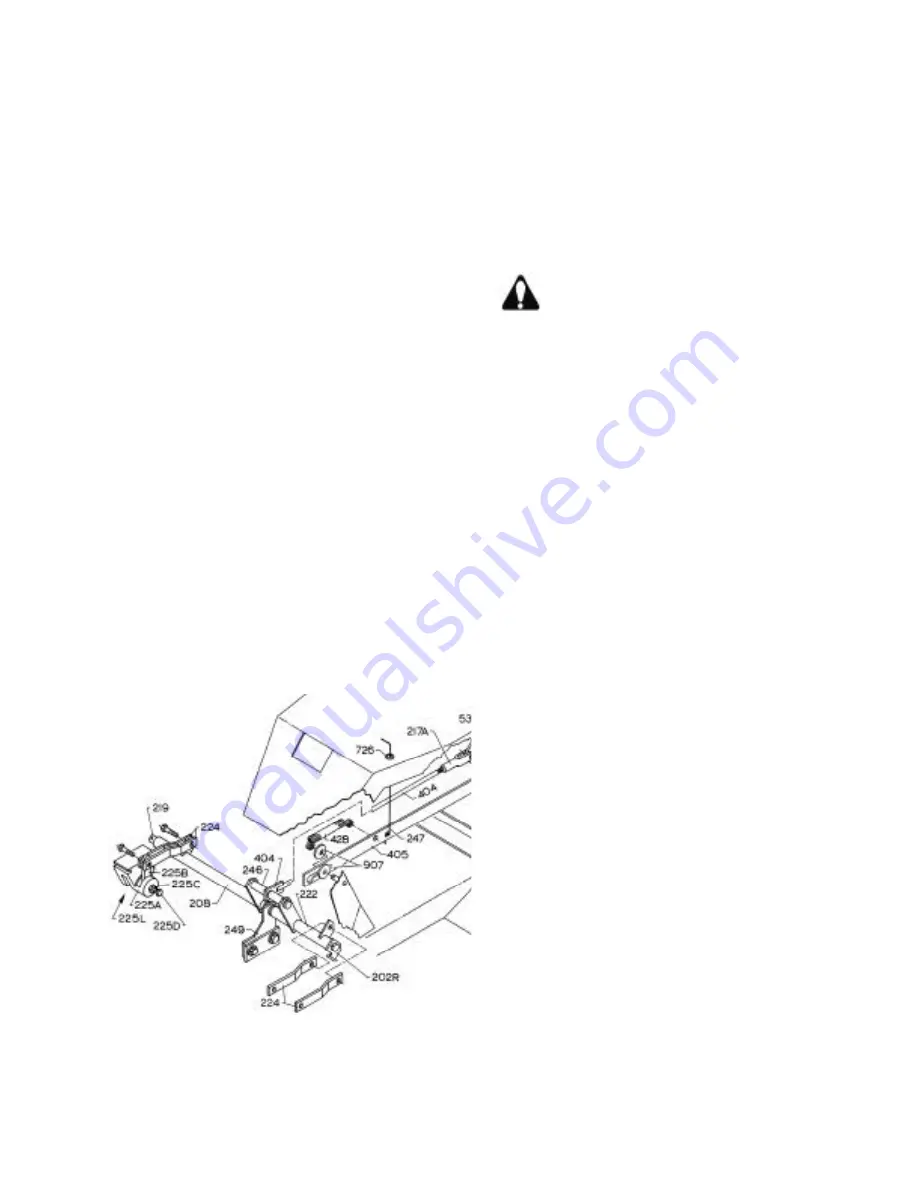

Consult the part photos and drawings at

the back of tractor manual to assist in

this procedure.

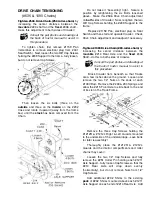

Release Parking Brake. Unscrew a few turns

the #225C Jam Nut on #225R & #225L Right &

Left Disk Brakes to release each Jam Nut’s

respective #225D Threaded Adjuster Pin.

Rotate the Adjuster Pin on each Disk Brake

in

(clockwise when viewing

face

of Brake) until it

stops...don’t overtighten, just tighten to the point

where it stops and the

pucks

(brake linings) are

tight on the Brake Disk.

Now counter-rotate (counter-clockwise) the

Adjuster Pin of each Disk Brake exactly 180

degrees. The pucks should have lost their grip on

their respective Disks and both Brake assemblies

should be free to move.

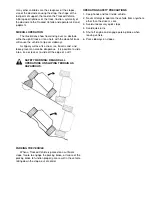

Push forward on the Parking Brake and watch

as each Disk Brakes’ #225B Lever begins to

rotate forward, and tighten the pucks of each

Brake on their respective Disk. The #246 Evener

Rod is the

central pull device

that connects the

two Disk Brakes together, and it

must be kept

parallel

to the #219 Pivot Rod.

If it is not parallel, determine which of the two

#208C Levers (connecting the #246 Evener) is

further rearward. Release the Brake. Rotate just

a few degrees counter-clockwise, the Adjuster Pin

of the Disk Brake that is closest to the most

rearward #208C Lever. Push forward on Brake

and recheck for parallelism of #246 Evener &

#219 Pivot...readjust if necessary. When

satisfied, hold each #225D Adjuster with wrench

and tighten its respective #225C Jam Nut.