2

(E)

2. Mounting Instructions

•

If excessive torque is applied on the spindle when screwing in the feeler, the internal

mechanisms can be damaged. Therefore, screw in the feeler with your hands, and never

use a tool.

Except when using a flat feeler, it is recommended to either attach the supplied spring

washer (nominal size: 2.5) or use a screw lock to prevent loosening of the feeler (tightening

torque reference value: 0.05–0.06 N·m).

•

The recommended dimension for the measuring unit mounting hole is ø9.7 ±0.15 mm

(0.38" ±0.006" dia.).

•

The mounting plate thickness is as follows.

DK805F Series: 9 to 11 mm (0.35" to 0.43")

•

The mounting parallelism affects the measuring accuracy. The mounting plate parallelism

and the squareness to the measuring surface should be held within 0.02 mm/14 mm

(0.0008"/0.55").

•

Be sure to use the supplied tightening nut, wave washer, clamp spanner and pin to mount

the measuring unit (Fig. 1).

Note

The tightening torque should be roughly that needed to completely flatten the wave washer.

Recommended tightening torque:

0.6 to 1.0 N·m

Maximum tightening torque:

2.0 N·m

•

Fix the cable in a suitable position to prevent possible cable breakage. Never handle the

cable by forcibly pulling or bending it. (Inside bend radius 40 mm/1.57" or more)

•

If the spindle is to be fixed to the machine, use coupling DZ-191 which is optionally

available. Refer to the DZ-191 Instruction Manual regarding the mounting procedure.

•

Use the fitting to be attached to the measuring unit as shown in Fig. 2. Especially, the

length of the M4 screw section to be inserted into the measuring unit should be 4.5 mm

(0.18") or less. If the screw is too long, the measuring unit may be damaged.

•

After the stem is secured, do not apply force in the rotational direction. This could cause

a failure.

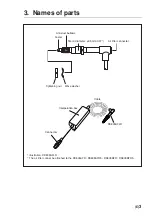

Fig.2 Dimensions of Fitting

Fig.1

Insert into the

measuring unit

O ring

M4

4.5/0.18" or less

φ

9/0.35" dia.

To orifice

tube

Pin

Measuring unit

Mounting

plate

Wave wahser

Tightening nut

Clamp spanner

Unit: mm/inch

φ

3/0.12" dia.

Summary of Contents for DK805A

Page 6: ... 4 J ...

Page 8: ...ii J ...

Page 20: ... 4 CS ...

Page 22: ...ii CS ...

Page 34: ... 4 E ...

Page 36: ...ii E ...

Page 48: ... 4 G ...

Page 50: ...ii G ...

Page 59: ...DK805AFR DK805AFR5 DK805AFLR DK805AFLR5 DK805BFR DK805BFR5 DK805BFLR DK805BFLR5 ...

Page 60: ...DK805AFR DK805AFR5 DK805AFLR DK805AFLR5 DK805BFR DK805BFR5 DK805BFLR DK805BFLR5 ...

Page 62: ...DK805AFR DK805AFR5 DK805AFLR DK805AFLR5 DK805BFR DK805BFR5 DK805BFLR DK805BFLR5 ...