SR77, CH33

(E)

3

SR77

■

■

■

■

■

Scale and slider installation notes

Notes

•

Do not turn on the power before installing the scale.

•

Install the scale with the opening on the scale unit facing downward. If the opening cannot be turned

downward, it should face horizontally. Never install it facing upward. (Fig. 1)

•

Remove off the coating around the tap hole to ground the scale unit using the installation surface contact

with the scale.

•

Be aware that the scale will be damaged if slider moved outside the measuring length (ML).

•

In environments where coolant can splash directly on the scale, be sure to mount a cover on the scale to

protect the scale from splashing. (Fig. 2)

•

The slider holders are used to secure the slider in place during transport. They are not guides for installation.

•

Do not take off the slider holders, if possible, until immediately before securing the slider.

•

Even if the slider holders are removed, the plastic hook provided on the slider allows the slider to

maintain an approximate positional relationship with the scale unit.

•

The plastic hook can come off if the slider is forcibly twisted or other excessive force is applied. If the

plastic hook comes off, return the plastic hook back to its original position before performing the

installation. (See Fig. 4.)

•

After removing the slider holder, be sure to take off the clamp nuts remaining on the scale.

•

Before installing the scale, check that the alignment of the installation surface (or installation brackets) is

within the standards.

•

Use a scale installation bracket, where applicable, having a length covering the entire scale length. The

parallelism of the scale may be harmed if only using a bracket divided for the installation section.

•

The foot plates on both ends and intermediate foot plate installed on the scale unit are used as the installation

guides.

•

Loosely turn the mounting screws first. Determine the alignment and then tighten the screws to fasten the

scale. (See Fig. 5.)

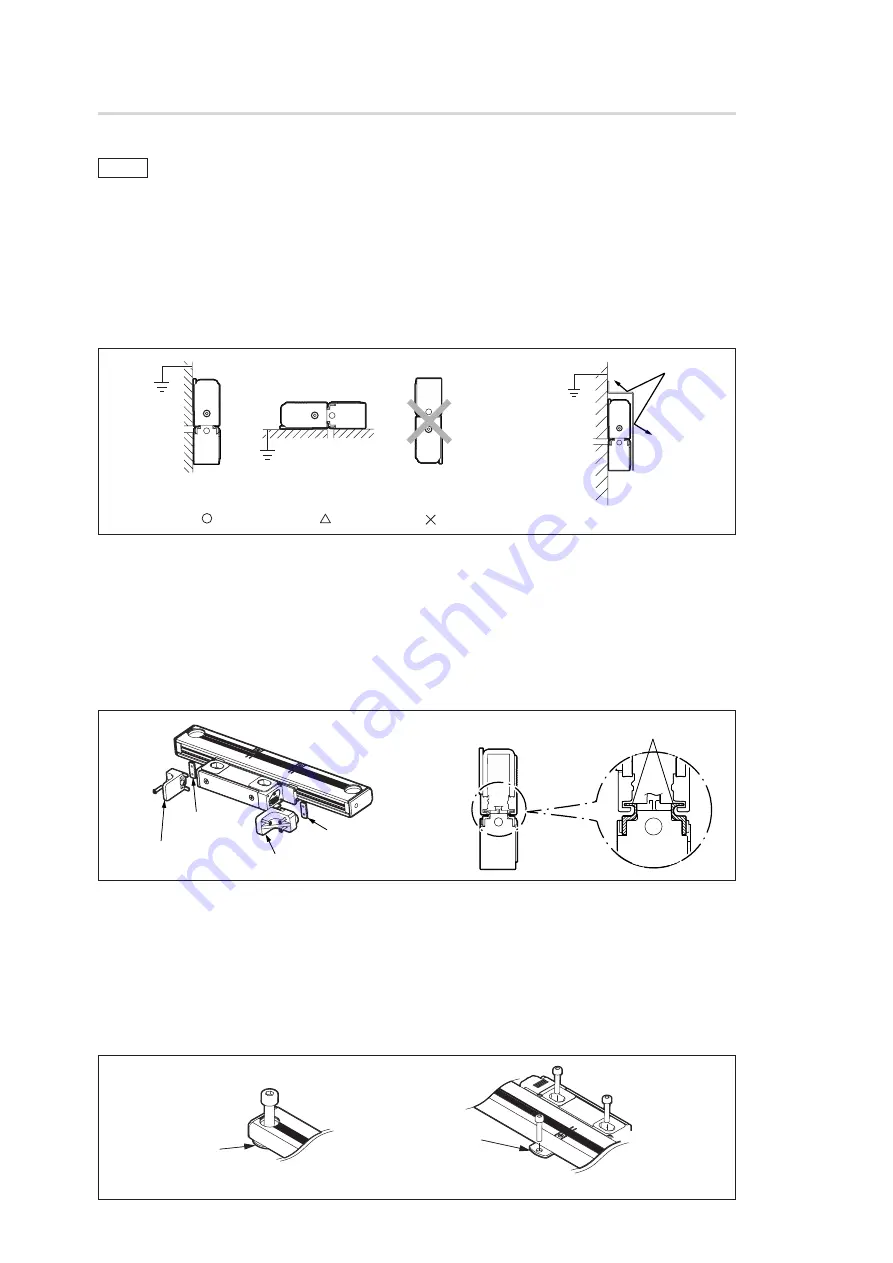

Fig. 1

Fig. 2

Opening facing

downward

( )

Opening facing

horizontally

( )

Opening

facing upward

( )

Coolant

Fig. 3

Fig. 4

Slider holder L

Slider holder R

Clamp nut

Clamp nut

Plastic hook

Fig. 5

Bring into contact

Both ends : M8

×

16 (20 N•m)

Intermediate foot plate : M4

×

10 (2.7 N•m)

Slider : M4

×

20 (2.7 N•m)

Bring into contact

Summary of Contents for SR77

Page 3: ...SR77 CH33 J 1...

Page 5: ...SR77 CH33 J 3 1 ML 2 SR77 4 3 5 5 2 1 M8 16 20 N m M4 10 2 7 N m M4 20 2 7 N m 4 L R...

Page 6: ...4 J SR77 CH33 1 1 6 7 5 0 05 0 1 MG 57 9 0 3 0 0 2 0 05 0 05 MG 57 9 0 3 7 2 mm mm...

Page 7: ...SR77 CH33 J 5 8 3 2 1 0 1 MG 0 05 MG 0 0 2 0 05 9 mm...

Page 8: ...6 J SR77 CH33 11 2 2 10 3 t 1 0 mm M5 0 1 MG t 1 0 mm mm...

Page 10: ...8 J SR77 CH33...

Page 18: ...8 E SR77 CH33...

Page 26: ...8 G SR77 CH33...

Page 27: ...SR77 CH33 C 1 Magnescale Co Ltd...

Page 29: ...SR77 CH33 C 3 2 1 L R M8 16 20 N m M4 20 2 7 N m M4 10 2 7 N m SR77 1 ML 2 4 5 3 4 5...

Page 30: ...4 C SR77 CH33 6 7 1 1 2 7 5 0 05 0 1 MG 57 9 0 3 0 0 2 57 9 0 3 0 05 0 05 MG...

Page 31: ...SR77 CH33 C 5 8 9 3 2 1 0 1 MG 0 05 MG 0 0 2 0 05...

Page 32: ...6 C SR77 CH33 11 10 0 1 MG t 1 0 mm 2 3 t 1 0 mm M5...