Axial Flux Start Guide

Step 3

– Drive Parameters

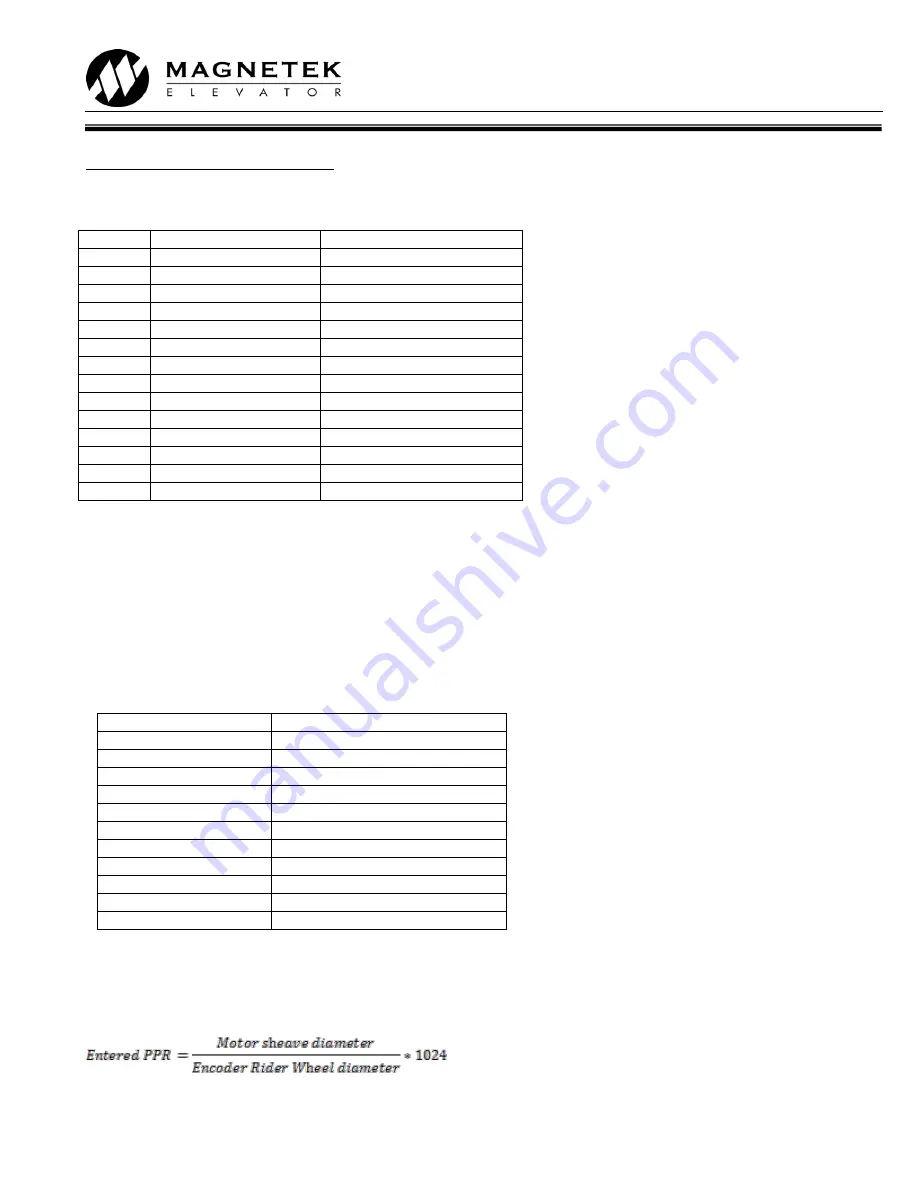

The following drive parameters should be entered for the Axial Flux drive:

Menu

Parameter

Correct Setting

U9

Drive Mode

“PM”

C1

Encoder Select

“Axial-Flux”

Motor Rotation

See table below

A4

Input L-L Volts

Enter Line to Line Voltage

A5

Rated Motor Power

From Motor Dataplate

Rated Motor Voltage

From Motor Dataplate

Rated Motor Current

From Motor Dataplate

Motor Poles

From Motor Dataplate

Rated Motor Speed

From Motor Dataplate

A1

Encoder Pulses

See table below

Motor Rotation (C1)

Ensure the motor is wired to the drive with U to U, V to V and W to W

If the motor sheave will rotate in a

Clockwise

direction for the car to travel up, set Motor Rotation (C1) to

FORWARDS

If the motor sheave will rotate in an

Anti-clockwise

direction for the car to travel up, set Motor Rotation (C1) to

REVERSE

Encoder Pulses (A1)

The encoder pulses in the A1 menu should be picked from the table below:

PM Motor Frame Types Encoder Pulse (A1)

MX05/10

14395 PPR

MX05/16

14452 PPR

MX06/05

17067 PPR

MX06/10

17067 PPR

MX06/16

17067 PPR

MX10/05

19819 PPR

MX10/08

19735 PPR

MX10/10

19819 PPR

MX10/15

19680 PPR

MX18

26050 PPR

MX20

12950 PPR (75mm Rider Wheel)

These values are simply a starting point. The final encoder PPR value will be entered once the motor can be run

at full speed as detailed in step 5.

If the motor does not conform to any of the types listed above, the PPR can be calculated using the diameter of

the sheave where the encoder rider wheel is running (This may differ from the sheave diameter on the motor

dataplate), and the diameter of the rider wheel supplied (37mm or 75mm).