Summary of Contents for DSD 412

Page 1: ...DSD 412 DC Elevator Drive Technical Manual CS00407 rev 06...

Page 6: ...6...

Page 102: ...MAINTENANCE 102 Figure 24 Connector and E prom Locations...

Page 103: ...MAINTENANCE 103 Figure 25 Test Point Locations...

Page 115: ...OUTLINE DRAWING 100A 115 Figure 26 Drive Chassis Outline DSD 412 100 Amp...

Page 116: ...OUTLINE DRAWING 190A 116 Figure 27 Drive Chassis Outline DSD 412 195 Amp...

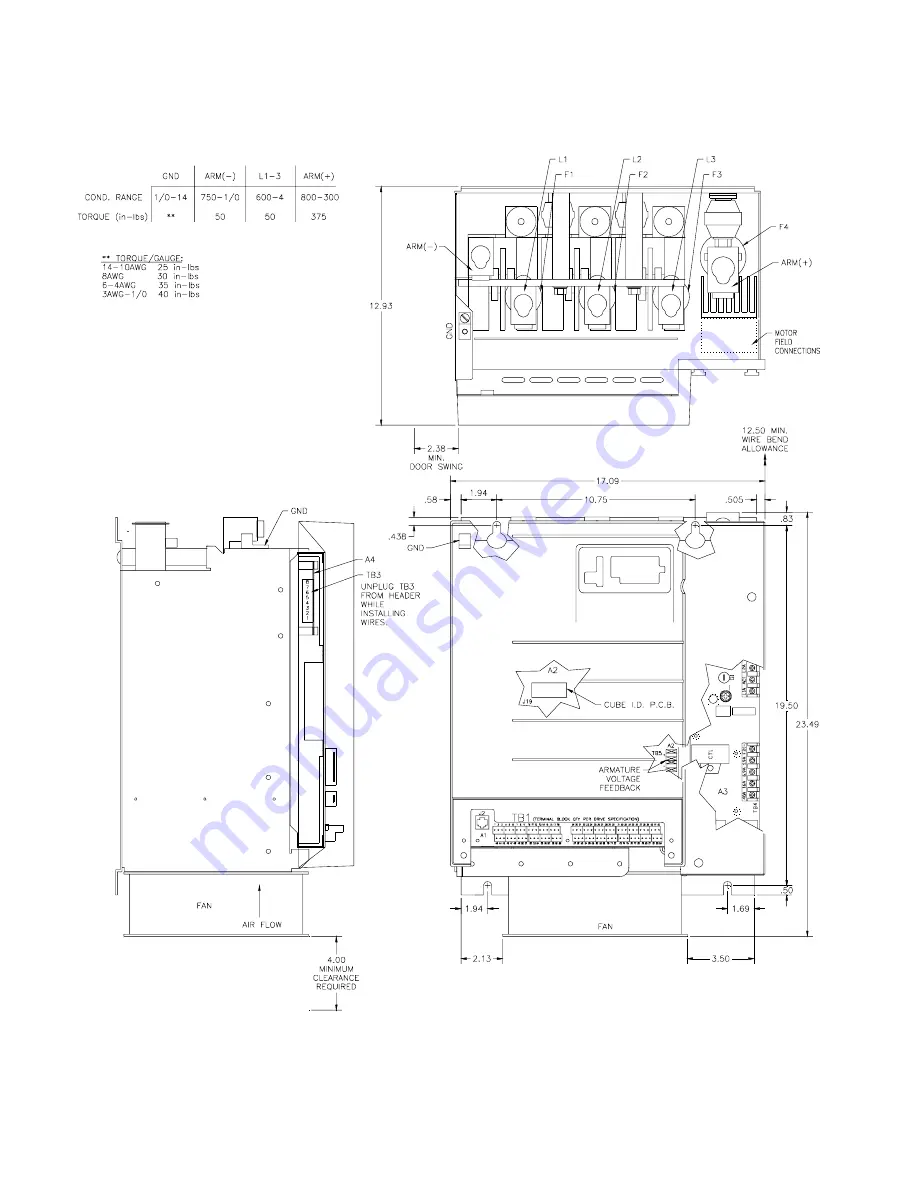

Page 117: ...OUTLINE DRAWING 300A 117 Figure 28 Drive Chasis Outline DSD 412 300 Amp...

Page 118: ...LAYOUT DRAWING 100A 118 Figure 29 Layout DSD 412 100 Amp A3 A1 A2 A2 L1 NEG GND L2 L3 POS...

Page 119: ...LAYOUT DRAWING 195A 119 Figure 30 Layout DSD 412 195 Amp A3 A1 A2 A2...

Page 120: ...LAYOUT DRAWING 300A 120 Figure 31 Layout DSD 412 300 Amp A3 A1 A2 A2...

Page 121: ......