Flex 6EX System Instruction Manual

March 2016

Page 32 of 38

7. OPERATING PROCEDURE

7.1 TRANSMITTER OPERATION

7.1.1 General Operating Procedure

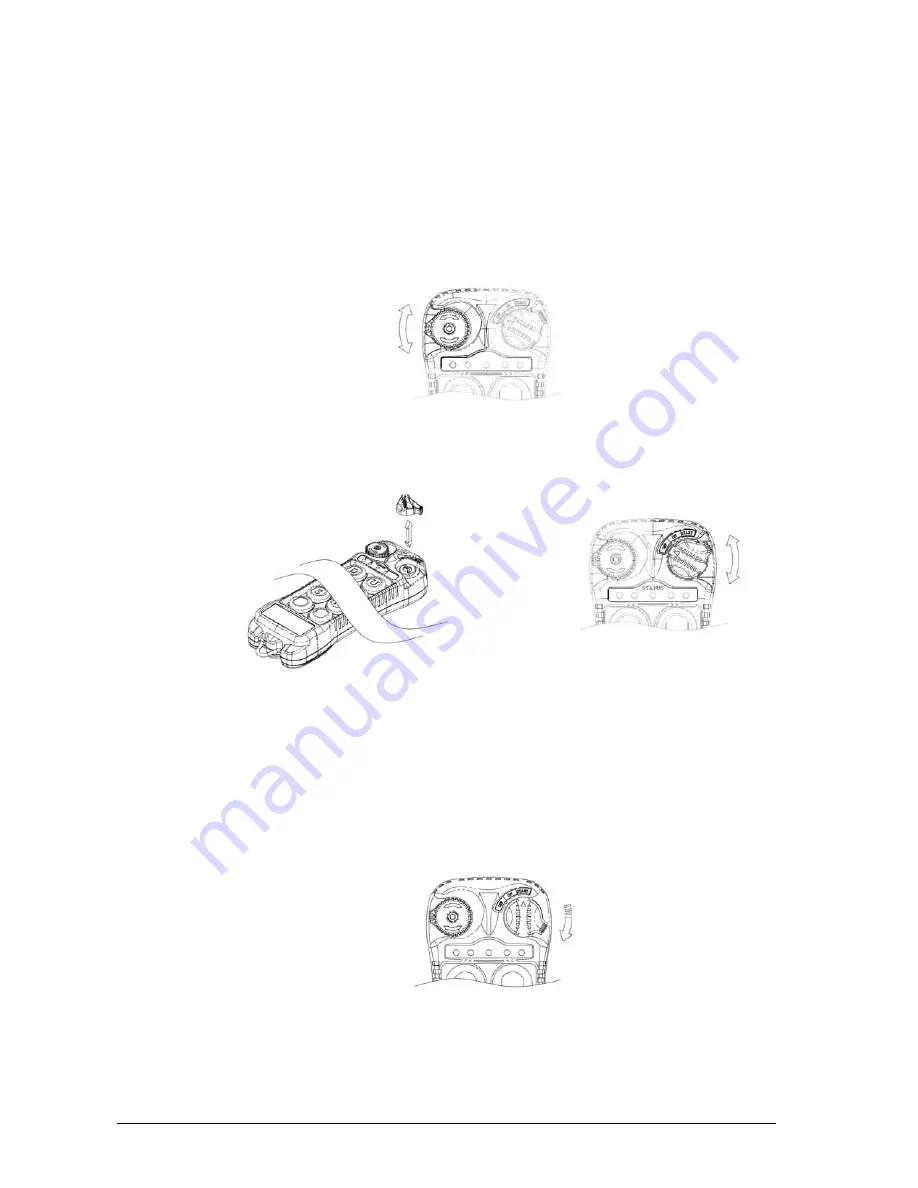

a.

Reset the red emergency stop button located on the top left hand side of the transmitter

handset by rotating it either clockwise or counter clockwise. The red button will pop up.

b.

Turn on the transmitter power by inserting the black-colored key into the power key slot

(located on the top right hand side of the transmitter handset), and rotate it clockwise to “On”

position.

c.

After turning on the transmitter power, check the Status LED on the transmitter handset for

any sign of system irregularities (refer to “Status Light Indicators & Warnings” on page 35). If

the system is normal the Status LED will light up green for two (2) seconds.

d.

If there are no signs of any system irregularities, then rotate the power key-switch further to

START position for up to 1.0 second to activate all transmitter push button functions and as

well as the receiver MAIN. Then press any push button on the transmitter to begin operation.

Pressing any push button prior to initiating the START command will result in no signal

transmitted (blinking orange light).