1.4 ELECTRICAL INSTALLATION

All basic interconnections (using the Digital Operator) are shown in Figures 1-3

through 1-6.

1.4.1 Main Circuit Input/Output

Complete wiring interconnections for the main circuit according to Tables 1-1 and 1-2,

while observing the following:

CAUTION

Use only factory supplied instructions to install dynamic braking

resistors. Failure to do so may cause equipment damage or

personal injury.

• Use 600 V vinyl-sheathed wire or equivalent. Wire size should be determined

considering voltage drop of leads.

• NEVER connect AC main power to output terminals T1 ( U ), T2 ( V ), and T3 ( W ).

• NEVER allow wire leads to contact the GPD 503 enclosure. Short-circuit may result.

• NEVER connect power factor correction capacitors or noise filter to GPD 503 output.

• SIZE OF WIRE MUST BE SUITABLE FOR CLASS I CIRCUITS.

• Use UL listed closed loop connectors or CSA certified ring connectors sized for the

selected wire gauge. The connectors are to be installed using the correct crimp tool

recommended by the connector manufacturer.

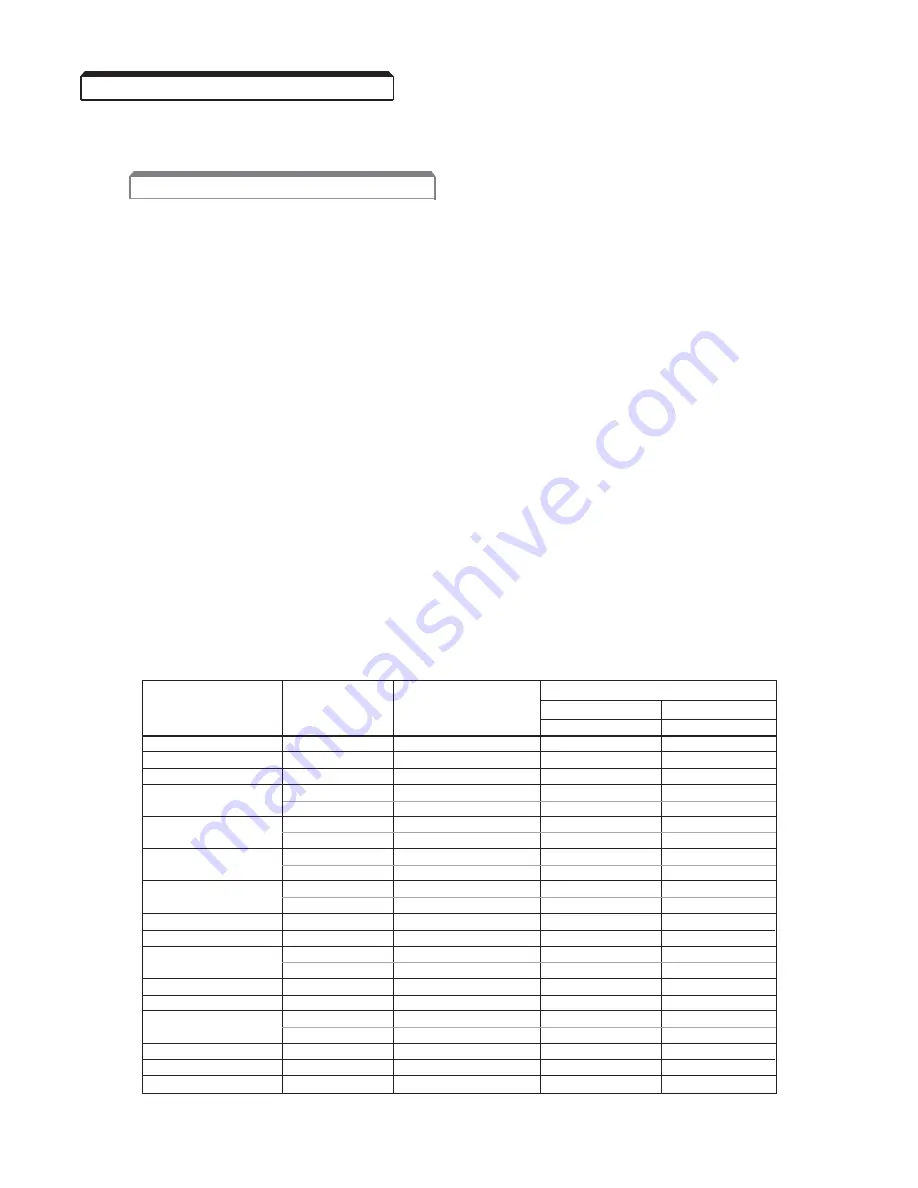

WIRE SIZE

TERMINAL

CLOSED-LOOP

CLAMPING TORQUE

AWG

mm

2

SCREW

CONNECTOR

STEEL

COPPER

lb-in

N-m

lb-in

N-m

20

0.5

M3.5

1.25 - 3.5

7.8

0.9

7.0

0.8

18

0.75

M4

1.25 - 4

13.0

1.5

10.4

1.2

16

1.25

M4

1.25 - 4

13.0

1.5

10.4

1.2

M4

2 - 4

13.0

1.5

10.4

1.2

14

2

M5

2 - 5

26.1

20.9

3.1

2.4

M4

3.5 - 4

13.0

1.5

10.4

1.2

12

3.5

M5

3.5 - 5

26.1

20.9

3.1

2.4

M4

5.5 - 4

13.0

1.5

10.4

1.2

10

5.5

M5

5.5 - 5

26.1

20.9

3.1

2.4

M5

8 - 5

26.1

20.9

3.1

2.4

8

8

M6

8 - 6

40.9

34.8

4.8

4.1

6

14

M6

14 - 6

40.9

34.8

4.8

4.1

4

22

M8

22 - 8

100.0

82.6

11.7

10.7

M8

38 - 8

100.0

82.6

11.7

10.7

2

38

M10

38 - 10

182.6

156.5

21.4

18.4

1/0

60

M10

60 - 10

182.6

156.5

21.4

18.4

3/0

80

M10

80 - 10

182.6

156.5

21.4

18.4

M10

100 - 10

182.6

156.5

21.4

18.4

4/0

100

M12

100 - 12

313.0

191.3

36.7

23.1

MCM300

150

M12

150 - 12

313.0

191.3

36.7

23.1

MCM400

200

M12

200 - 12

313.0

191.3

36.7

23.1

MCM650

325

M12

325 - 12

313.0

191.3

36.7

23.1

1-2