Pedestrian Pivot Barrier

MPP-112 / MPP-122 / MPP-132 / MPP-212 / MPP-222

Assembly and installation

34

5817,0016EN / Version 00

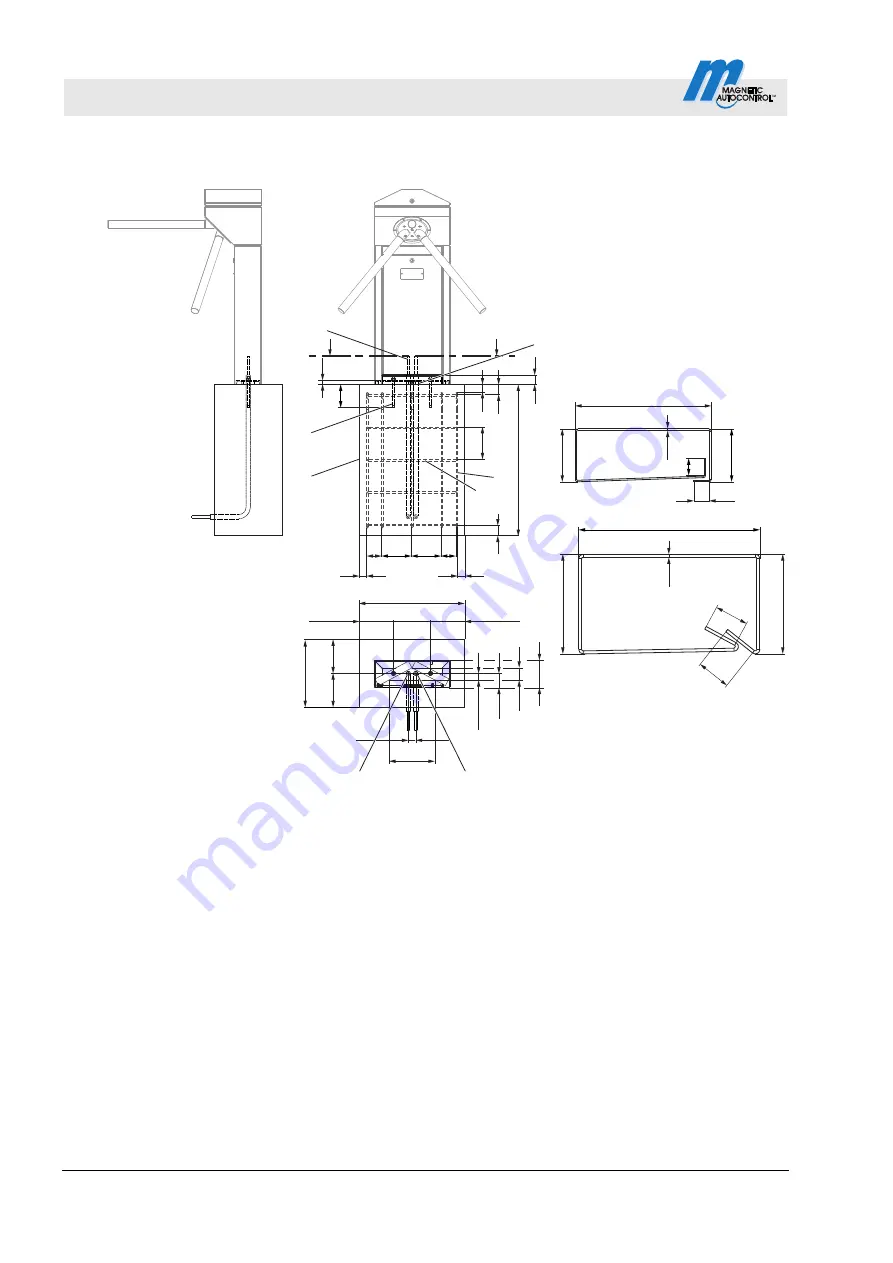

7.3.1 Foundation plan MPP-112, MPP-132 and MPP-212

Mag00425a

ca.196

min.

180

40

360

min.

min. 560

800

ca. 244

min. 180

min. 180

1

5

4

3

2

6

6

36

76

65

145

A

90

20

50

172

79 157

157 79

40

40

53

53

40

min.

180

B

90

80

280

280

720

Æ

8

A

90

90

264

480

B

Æ

8

264

Fig. 9: Foundation plan MPP-112, MPP-132 and MPP-212,

here illustrated MPP-112 (dimensions in mm)

For indoor applications, reinforcement is not required.

1

Foundation level and horizontal

2

Foundation depth: at least 800 mm, frost-protected

foundation depth to be adjusted to the local situation.

3

Concrete (C25/30) or corresponding continuous industrial floor.

In case of flagging make sure that the foundation anchors are

secured firmly in the foundation. If necessary, use longer anchors.

4

Foundation anchors M12x145, tightening torque: 50 Nm,

Diameter drilling hole 12 mm, drilling hole depth 90 mm

5

Have cables overlapping for approx. 2 m of the conduits

6

Empty conduits for mains supply and control line

Inner diameter 20 mm each