4

45-610 Displacer Type Liquid Level Switches and Proof-er

®

Switches

1

5

2

3

4

3

2

1

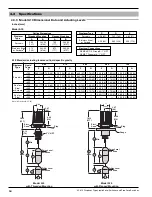

Figure 1

Switch position

on rising level

1

5

2

3

4

3

2

1

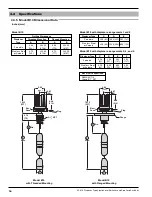

Figure 2

Switch position

on falling level

1.0 Introduction

Displacement type level switches offer the industrial user a wide

choice of alarm and control configurations. These units utilize

simple buoyancy principle and are well suited for simple or

complex applications.

1.1

Principle of Operation

1.1.1 Displacer Controls

The design of displacer operated level switches is based upon

the principle that a magnetic field will not be affected by non-

magnetic materials such as 316 stainless steel. In this case, the

displacer moves a magnetic attraction sleeve within a non-mag-

netic enclosing tube and actuates a magnetic switch mechanism.

The enclosing tube provides a pressure seal to the chamber and,

therefore, to the process.

1.2

Operating Cycle

A spring is loaded with a weighted displacer

➀

which is heavier

than the liquid. Immersion of the displacers caused by rising

liquid level imparts buoyancy forces on the displacer allowing the

spring to compress. The attraction sleeve

➁

attached to the spring,

moves upward into the field of a permanent magnet

➂

. The

movement of the magnet toward the sleeve causes the switch

➃

to

actuate. A non-magnetic barrier tube

➄

provides a static pressure

boundary between the switch mechanism and the displacer assem-

bly. As the liquid level falls, the displacer lowers, causing the spring

to extend, and moving the attraction sleeve out of the magnetic

field of the switch mechanism. This allows the switch to again

change position and to break or make. See Figures 1 and 2.

1.3

Floating Roof Detection

The spring is loaded with a displacer weight suspended from a

stainless steel cable. As the floating roof rises, the weight is lifted

by the roof allowing the spring to compress, the attraction

sleeve to move upward into the field of the switch magnet and

the switch to actuate. As the roof lowers, the weight again hangs

free causing the spring to extend, the sleeve to move downward

and the switch to reset. The displacers are usually fabricated

from ductile metals, such as brass, to prevent sparking when the

displacer makes contact with the roof.

1.4

Operating Cycle — Proof-er Control Option

The purpose of the Proof-er is to check the operation of a

displacer control without having to raise the level in the tank.

This is accomplished by pulling downward on the Proof-er

cable. This causes the spring loaded lever arm to lift the switch

actuator, simulating a high or high–high level condition.

When the cable is released, the Proof-er returns the actuator to

its original position resuming normal operation.