45-610 Displacer Type Liquid Level Switches and Proof-er

®

Switches

7

NOTE: On high temperature applications above +250° F (+121° C),

high temperature wire should be used between control and

first junction box located in a cooler area. On non-hazardous

applications, flexible conduit may be used between the con-

trol and the first junction box.

6. Bring supply wires through conduit entry. Route extra wire

around enclosing tube under baffle plate, and connect

then to the appropriate terminals. Refer to Figures 4–9 for

wiring diagrams of Dry Contact Switch Series B, C, D, F,

O and Q only. For wiring diagrams for Series HS, J, and K

refer to the specific bulletin listed in the chart below:

NOTE: For models with a Series HS switch with high temperature

lead wire, the leads are routed out through the conduit open-

ing by the factory. A suitable conduit box should be provided

for the connection of the leads to the control wiring.

7. Dress wiring to ensure no interference or contact with tilt

of switch, or replacement of switch housing cover.

NOTE: Observe all applicable electrical codes and proper wiring

procedures.

Prevent moisture seepage into the enclosure by installing

approved seal-drain fittings in the conduit run leading into

the unit.

Caution:

In hazardous areas, do not power the unit until the

conduit is sealed and the enclosure cover is screwed

down securely.

8. Test switch action by varying liquid level or manually

moving displacers.

9. Replace housing cover.

10. If control has been furnished with an explosion proof or

moisture proof (gasketed) switch housing, it must be

sealed at the conduit outlet with a suitable compound or

non-hardening sealant to prevent entrance of air.

NOTE: If switch mechanism fails to function properly, check vertical

alignment of control housing and consult installation bulletin

on switch mechanism furnished.

Switch Series

Description

Bulletin

Letter

No.

B, C, D, F, O, Q

Dry Contact Switch

42-683

HS

Hermetically Sealed Snap Switch

42-694

J

Bleed Type Pneumatic Switch

42-685

K

Non-Bleed Type Pneumatic Switch

42-686

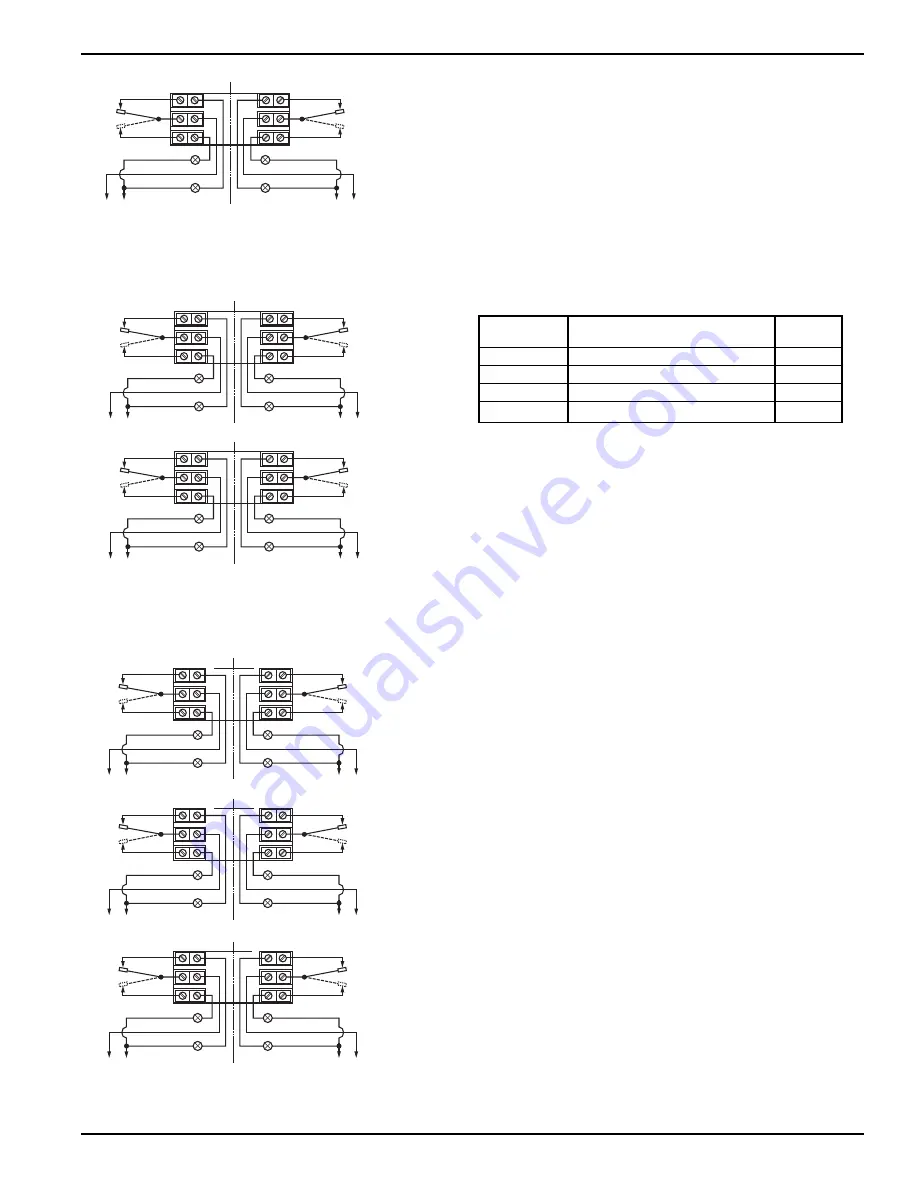

INTERNAL

CIRCUIT

(RIGHT)

SWITCH

INTERNAL

CIRCUIT

(LEFT)

SWITCH

1

2

3

LOAD

Close on high level (NO)

COMMON (C)

Close on low level (NC)

LINE

4

5

6

LOAD

Close on high level (NO)

COMMON (C)

Close on low level (NC)

LINE

LOAD

LOAD

NOTES:

1. Double pole action is obtained by simultaneous operation of the

right and left side single pole switches.

2. Rising Level Closes Contacts 5 & 6 and 2 & 3.

3. Falling Level Closes Contacts 4 & 5 and 1 & 2.

INTERNAL

CIRCUIT

(RIGHT)

SWITCH

INTERNAL

CIRCUIT

(LEFT)

SWITCH

INTERNAL

CIRCUIT

(RIGHT)

SWITCH

INTERNAL

CIRCUIT

(LEFT)

SWITCH

1

2

3

LOAD

Close on high level (NO)

COMMON (C)

Close on low level (NC)

LINE

4

5

6

LOAD

Close on high level (NO)

COMMON (C)

Close on low level (NC)

LINE

LOAD

LOAD

UPPER LEVEL RANGE OPERATES

UPPER SWITCH MECHANISM

1

2

3

LOAD

Close on high level (NO)

COMMON (C)

Close on low level (NC)

LINE

4

5

6

LOAD

Close on high level (NO)

COMMON (C)

Close on low level (NC)

LINE

LOAD

LOAD

LOWER LEVEL RANGE OPERATES

LOWER SWITCH MECHANISM

NOTES:

1. Double pole action is obtained by simultaneous operation of the

right and left side single pole switches.

2. Rising Level Closes Contacts 5 & 6 and 2 & 3.

3. Falling Level Closes Contacts 4 & 5 and 1 & 2.

INTERNAL CIRCUIT

(RIGHT) SWITCH

1

2

3

LOAD

Close on high level (NO)

COMMON (C)

Close on low level (NC)

LINE

4

5

6

INTERNAL CIRCUIT

(LEFT) SWITCH

LOAD

Close on high level (NO)

COMMON (C)

Close on low level (NC)

LINE

LOAD

LOAD

UPPER LEVEL RANGE OPERATES

UPPER SWITCH MECHANISM

INTERNAL CIRCUIT

(RIGHT) SWITCH

1

2

3

1

2

3

LOAD

Close on high level (NO)

COMMON (C)

Close on low level (NC)

LINE

4

5

6

INTERNAL CIRCUIT

(LEFT) SWITCH

LOAD

Close on high level (NO)

COMMON (C)

Close on low level (NC)

LINE

LOAD

LOAD

MIDDLE LEVEL RANGE OPERATES

MIDDLE SWITCH MECHANISM

INTERNAL CIRCUIT

(RIGHT) SWITCH

LOAD

Close on high level (NO)

COMMON (C)

Close on low level (NC)

LINE

4

5

6

INTERNAL CIRCUIT

(LEFT) SWITCH

LOAD

Close on high level (NO)

COMMON (C)

Close on low level (NC)

LINE

LOAD

LOAD

LOWER LEVEL RANGE OPERATES

LOWER SWITCH MECHANISM

NOTES:

1. Double pole action is obtained by simultaneous operation of the

right and left side single pole switches.

2. Rising Level Closes Contacts 5 & 6 and 2 & 3.

3. Falling Level Closes Contacts 4 & 5 and 1 & 2.

Figure 4 – Single Stage with DPDT contacts

Figure 5 – Dual Stage with DPDT contacts

Figure 6 – Triple Stage with DPDT contacts