4

Periodic inspections are a necessary means to keep your Magnetrol level control in good working order. This control

is, in reality, a safety device to protect the valuable equipment it serves. Therefore, a systematic program of

“Preventive Maintenance” should be implemented when control is placed into service. If the following sections on

“What to Do” an “What to Avoid” are observed, your control will provide reliable protection of your capital equipment.

PREVENTIVE MAINTENANCE

WHAT TO DO

1.

Keep Control Clean

Be sure the switch housing cover is always in place on

the control. This cover is designed to keep dust and dirt

from interfering with switch mechanism operation. In

addition, it protects against damaging moisture and

acts as a safety feature by keeping bare wires and ter-

minals from being exposed. Should the housing cover

become damaged or misplaced, order a replacement

immediately.

2. Inspect Switch Mechanisms, Terminals and

Connections Monthly

– Mercury switches may be visually inspected for short

circuit damage. Check for small cracks in the glass

tube containing the mercury. Such cracks can allow

entrance of air into the tube causing the mercury to

“oxidize”. This is noticeable as the mercury will

appear dirty and have a tendency to “string out” like

water, instead of breaking into clean round pools. If

these conditions exist, replace the mercury switch

immediately.

– Dry contact switches should be inspected for exces-

sive wear on actuating lever or misalignment of

adjusting screw at point of contact between screw

and lever. Such wear can cause false switch actuat-

ing levels. Adjust switch mechanism to compensate

(if possible) or replace switch.

DO NOT operate your control with defective maladjusted

switch mechanisms (refer to bulletin on switch mechanism

furnished for service instructions).

– Magnetrol controls may sometimes be exposed to

excessive heat or moisture. Under such conditions,

insulation on electrical wires may become brittle,

eventually breaking or peeling away. The resulting

“bare” wires can cause short circuits. Check wiring

carefully and replace at first sign of brittle insulation.

– Vibration may sometimes cause terminal screws to

work loose. Check all terminal connections to be cer-

tain that screws are tight.

– On units with pneumatic switches, air (or gas) oper-

ating medium lines subjected to vibration, may even-

tually crack or become loose at connections causing

leakage. Check lines and connections carefully and

repair or replace, if necessary.

NOTE: As a matter of good practice, spare switches should

be kept on hand at all times.

3. Inspect Entire Unit Periodically

Isolate control from vessel. Raise and lower liquid level

to check for switch contact and reset.

WIRING (cont.)

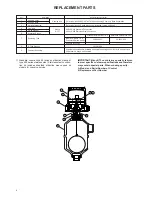

Set screw

Set screw

Locking screw

Set screw

Position

screw

CAUTION:

- DO NOT attempt to reposition NEMA 4 /

NEMA 7/9 housings without loosening the

set screws; CENELEC/BASEEFA housings

MAY NOT BE REPOSITIONNED. ALWAYS

retighten set screw(s) after repositionning.

- DO NOT attempt to unscrew cover of CEN-

ELEC/BASEEFA housings before loosening

locking screw in base of housing. ALWAYS

retighten locking screw after replacing cover.

Figure 4c

Figure 4a

Figure 4b

NEMA 4x

NEMA 7/9

CENELEC/BASEEFA

OBSERVE ALL APPLICABLE ELECTRICAL CODES AND PROPER WIRING PROCEDURES