13

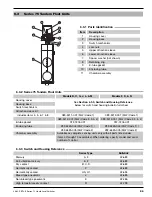

46-620 B73 & Series 75 Liquid Level Switche

s

Minimum SG given is for single switch units with -1 materials of

construction. Consult factory for other configurations.

Switch actuating levels (HL & LL) are given for minimum specific

gravity materials of construction –1 and single switch units. Consult

factory for other configurations.

304 Stainless steel only

316 Stainless steel only

These dimensions increase by 2.19 (55) with Series HS switches

with terminal blocks.

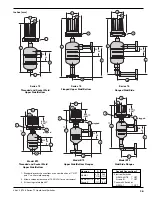

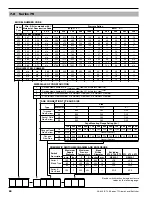

STAINLESS STEEL CHAMBERS WITH 1 INCH CONNECTIONS

INCHES

MILLIMETERS

NPT &

Flanged

Flanged

Actuating

NPT &

Flanged

Flanged

Actuating

Min.

Socket Weld

Upper Side/Btm

Side/Side

Levels

Socket Weld

Upper Side/Btm

Side/Side

Levels

SG

A

B

C

A

B

C

A

B

C

HL

LL

A

B

C

A

B

C

A

B

C

HL

LL

B73

0.59 6.36 3.34 17.44 9.25 6.25 20.32 9.90 6.25 21.00 1.22 2.10

151

84

442

235

159

515

251

159

532

30

53

C75

0.60 8.50 3.61 22.06 11.56 6.68 25.12 12.21 6.68 25.75 2.75 3.62

216

92

560

294

170

638

310

170

654

70

92

J75

0.57 9.25 3.61 23.06 12.31 6.68 26.12 12.96 6.68 26.75 2.93 3.78

235

92

586

313

170

663

329

170

679

74

96

O75

0.85 8.50 2.71 21.87 11.56 5.68 24.93 12.21 5.68 25.62 2.44 3.50

216

69

555

294

144

633

310

144

651

62

89

O75

0.85 8.50 2.59 21.56 11.56 5.56 24.62 12.21 5.56 25.43 2.44 3.50

216

66

548

294

141

625

310

141

646

62

89

P75

0.75 8.50 3.09 21.93 11.56 6.12 25.00 12.21 6.12 25.68 2.56 3.50

216

78

557

294

155

635

310

155

652

65

89

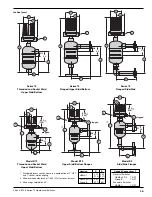

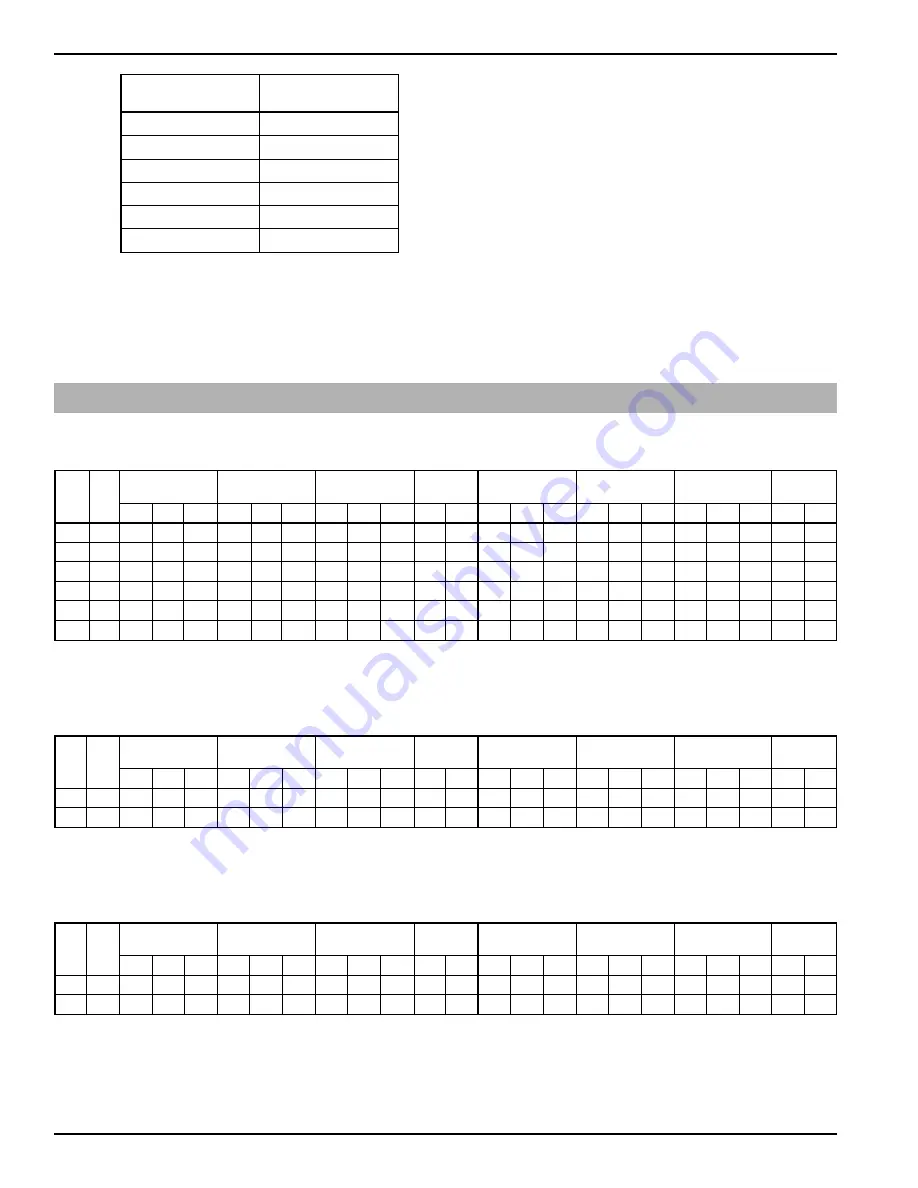

5.2

Physical

STAINLESS STEEL CHAMBERS WITH 1

1

⁄

2

INCH CONNECTIONS

INCHES

MILLIMETERS

NPT &

Flanged

Flanged

Actuating

NPT &

Flanged

Flanged

Actuating

Min.

Socket Weld

Upper Side/Btm

Side/Side

Levels

Socket Weld

Upper Side/Btm

Side/Side

Levels

SG

A

B

C

A

B

C

A

B

C

HL

LL

A

B

C

A

B

C

A

B

C

HL

LL

C75 0.60 8.50 4.22 12.56 12.56 7.68 16.63 13.21 7.68 17.31 2.13 3.00

215

107

319

319

195

422

335

195

439

54

76

J75

0.57 9.25 4.22 13.56 13.31 7.68 17.63 13.96 7.68 18.25 2.75 3.50

234

107

344

338

195

448

354

195

464

70

89

STAINLESS STEEL CHAMBERS WITH 2 INCH CONNECTIONS

INCHES

MILLIMETERS

NPT &

Flanged

Flanged

Actuating

NPT &

Flanged

Flanged

Actuating

Min.

Socket Weld

Upper Side/Btm

Side/Side

Levels

Socket Weld

Upper Side/Btm

Side/Side

Levels

SG

A

B

C

A

B

C

A

B

C

HL

LL

A

B

C

A

B

C

A

B

C

HL

LL

C75 0.60 8.25 4.37 12.69 12.56 7.68 17.00 13.21 7.68 17.69 1.75 2.63

209

110

322

319

195

431

335

195

449

44

69

J75

0.57 9.00 4.34 13.69 13.31 7.68 18.00 13.96 7.68 18.69 2.98 3.13

228

110

348

338

195

457

354

195

475

60

80

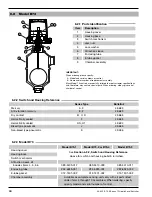

Maximum Process

Temperature

Temperature

Classification

< 85° C

T6

< 100° C

T5

< 135° C

T4

< 200° C

T3

< 300° C

T2

< 450° C

T1

These units are in comformity with IECEx KEM 05.0020X

Classification Ex d

II

C T6

Tambient -40° C to +70° C