46-620 B73 & Series 75 Liquid Level Switches

24

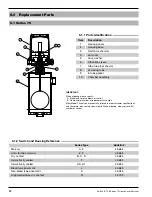

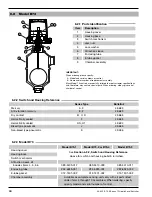

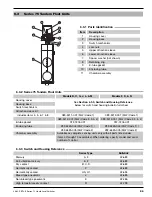

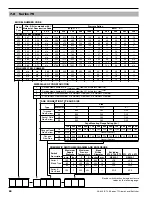

ELECTRIC SWITCH MECHANISM AND ENCLOSURE

Switch Description

Process

Temperature

Range

° F (° C)

Contacts

Set

Points

Construction Code 1

(except Model S75)

Construction Codes 2, 3 & 4

and Model S75

NEMA 4X/7/9 Aluminum Enclosure

Class I, Div 1

Groups

C & D

Class I, Div 1

Groups

B, C & D

ATEX

Class I, Div 1

Groups

C & D

Class I, Div 1

Groups

B, C & D

ATEX

Series A Mercury

-20 to +550

(-29 to +288)

SPDT

1

2

3

AKA

ALA

n/a

AKJ

ALJ

n/a

ACC

ADC

n/a

AKB

ALB

AMB

AKK

ALK

AMK

AC9

AD9

AE9

DPDT

1

2

ANA

AOA

ANJ

AOJ

AFC

AGC

ANB

AOB

ANK

AOK

AF9

AG9

Series B Snap

-40 to +250

(-40 to +121)

SPDT

1

2

3

BKA

BLA

BMA

BKJ

BLJ

BMJ

BCC

BDC

BEC

BKB

BLB

BMB

BKK

BLK

BMK

BC9

BD9

BE9

DPDT

1

2

BNA

BOA

BNJ

BOJ

BFC

BGC

BNB

BOB

BNK

BOK

BF9

BG9

Series C Snap

-40 to +450

(-40 to +232)

SPDT

1

2

3

CKA

CLA

CMA

CKJ

CLJ

CMJ

CCC

CDC

CEC

CKB

CLB

CMB

CKK

CLK

CMK

CC9

CD9

CE9

DPDT

1

2

CNA

COA

CNJ

COJ

CFC

CGC

CNB

COB

CNK

COK

CF9

CG9

Series D Snap

-40 to +250

(-40 to +121)

SPDT

1

2

3

DKB

DLB

n/a

DKK

DLK

n/a

DC9

DD9

n/a

DKB

DLB

DMB

DKK

DLK

DMK

DC9

DD9

DE9

DPDT

1

2

DNB

DOB

DNK

DOK

DF9

DG9

DNB

DOB

DNK

DOK

DF9

DG9

Series E

Vibration Resistant

Mercury

-20 to +550

(-29 to +288)

SPDT

1

2

3

EKA

ELA

n/a

EKJ

ELJ

n/a

ECC

EDC

n/a

EKB

ELB

EMB

EKK

ELK

EMK

EC9

ED9

EE9

DPDT

1

2

ENA

EOA

ENJ

EOJ

EFC

EGC

ENB

EOB

ENK

EOK

EF9

EG9

Series F

Hermetically Sealed

Snap

-50 to +750

(-46 to +399)

SPDT

1

2

FKA

FLA

FKJ

FLJ

FCC

FDC

FKB

FLB

FKK

FLK

FC9

FD9

DPDT

1

2

FNA

FOA

FNJ

FOJ

FFC

FGC

FNB

FOB

FNK

FOK

FF9

FG9

Series HS

Hermetically Sealed

5 amp Snap

with wiring leads

-50 to +550

(-46 to +288)

SPDT

1

2

HMJ

HMN

HMK

HMP

n/a

HMJ

HMN

HMK

HMP

n/a

DPDT

1

2

HMS

HMY

HMT

HMZ

HMS

HMY

HMT

HMZ

Series HS

Hermetically Sealed

5 amp Snap

with terminal block

-50 to +550

(-46 to +288)

SPDT

1

HM3

HM4

HA9

HM3

HM4

HA9

DPDT

1

HM7

HM8

HB9

HM7

HM8

HB9

Series H1

Hermetically Sealed

1 amp Snap

with wiring leads

-50 to +750

(-46 to +399)

SPDT

1

HKJ

HKK

n/a

HKJ

HKK

n/a

SPDT

2

HKN

HKP

HKN

HKP

Series R

High Temperature Snap

-40 to +1000

(-40 to +538)

SPDT

1

2

RKM

RLM

RKW

RLW

RU5

RV5

RKM

RLM

RKW

RLW

RU5

RV5

Series 3 Mercury

-20 to +750

(-29 to +399)

SPDT

1

2

3

3KA

3LE

3ME

3KJ

3LG

3MG

3CC

3DE

3EE

3KB

3LB

3MB

3KK

3LK

3MK

3C9

3D9

3E9

DPDT

1

2

3NA

3OA

3NJ

3OJ

3FC

3GC

3NB

3OB

3NK

3OK

3F9

3G9

Series 2 Vibration

Resistant Mercury

-20 to +750

(-29 to +399)

SPDT

1

2

3

2KA

2LE

2ME

2KJ

2LG

2MG

2CC

2DE

2EE

2KB

2LB

2MB

2KK

2LK

2MK

2C9

2D9

2E9

DPDT

1

2

2NA

2OA

2NJ

2OJ

2FC

2GC

2NB

2OB

2NK

2OK

2F9

2G9

12

14

Minimum specific gravity ratings apply only to

single stage units. Consult factory for two or

three stage units.

Models are limited to maximum temperature

rating of selected switch mechanism. See

Switch Mechanism Charts above.

Use caution when specifying carbon steel and stainless steel for tempera-

tures greater than +800° F (+427° C), as they become sensitized.

S75, V75 & Z75 contain 17–7 ph floats.

The O75 and P75 are not available with 1

1

⁄

2

" and 2" process connections.

Valid for Models V75 & Z75 only.

Consult factory for NEMA 4X/7/9 cast iron housings.

Process temperature based on +100° F (+38° C) ambient.

Drain or uncontrolled housing heater available in NEMA 4X/7/9 enclo-

sures. Consult factory for standard part number.

On steam applications, use Series 3 mercury switches with beaded leads.

On steam applications, use Series 2 vibration resistant mercury switches

with beaded leads.

HS and H1 switches can be used with materials of construction code 1

only on models S75, V75 & Z75.

On steam and other condensing applications, temperature down-rated to

+400° F (+204° C) process at +100° F (+38° C) ambient.

R series switches supplied in cast iron switch enclosures.

11

12

13

14

11

13

12

13

12