3

46-620 B73 & Series 75 Liquid Level Switche

s

3. Tighten set screw(s) at base of switch housing.

4. Unscrew and remove switch housing cover. The threads

have been lubricated to facilitate removal.

NOTE: For supply connections, use wire with a minimum rating of

+167° F (+75° C) as required by process conditions. Use a

minimum of 14 AWG wire for power and ground field wires.

NOTE: Housing must be grounded via protective ground screw in the

base of the housing.

NOTE: On high temperature applications (above +250° F [+121° C] in

float chamber), high temperature wire should be used

between control and first junction box located in a cooler area.

On non-hazardous applications, flexible conduit may be used

between the control and the first junction box.

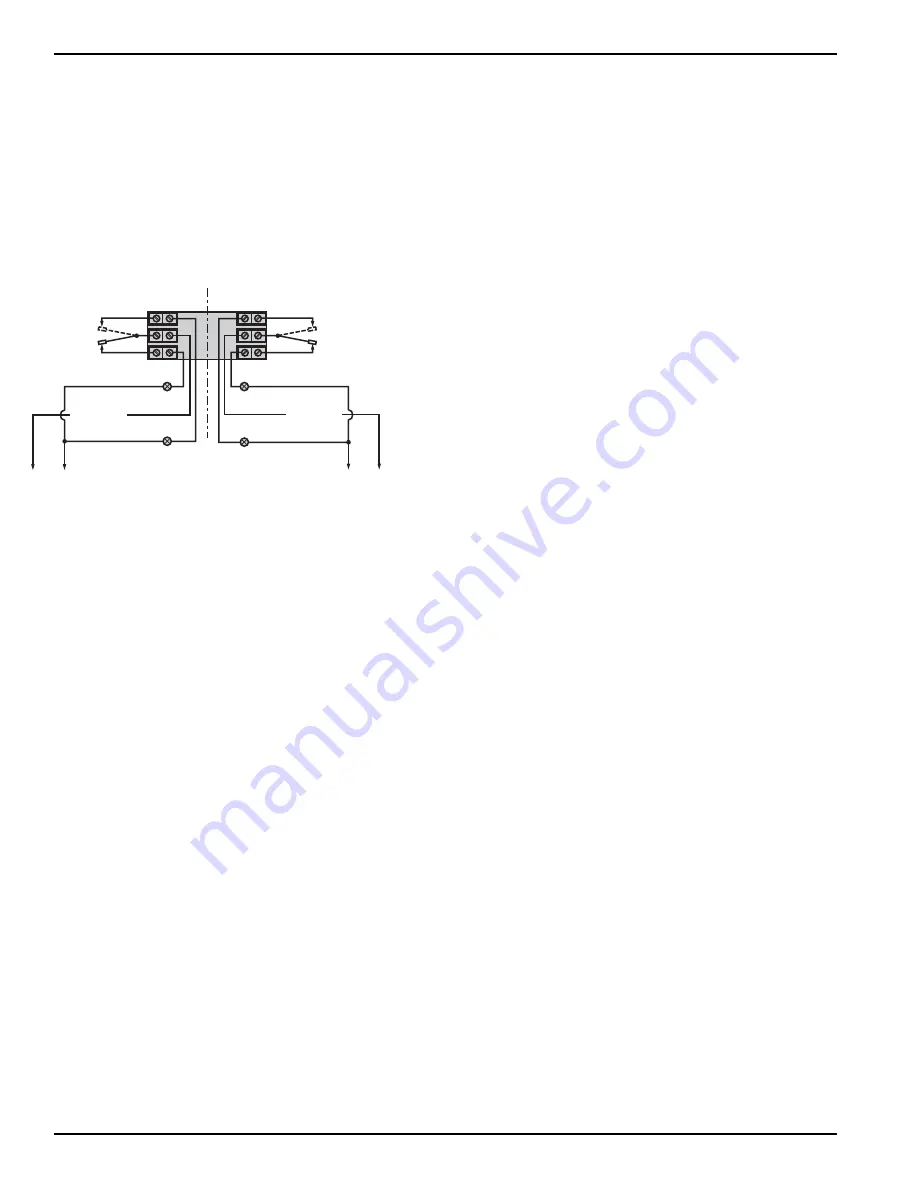

5. The switch terminals are located next to the conduit

outlet to facilitate wiring. Bring supply wires through

conduit outlet. Route extra wire around enclosing tube

under the baffle plate, and connect them to the proper

terminals. Refer to the wiring diagram,

Figure 3

, or your

switch bulletin for this information.

NOTE: For models with Series HS or H1 switches with high tempera-

ture lead wire, the leads are routed out through the conduit

opening by the factory. A suitable conduit box should be

provided for the connection of the leads to the control wiring.

6. Dress wiring to ensure no interference or contact with tilt

of switch or replacement of switch housing cover.

Caution:

Observe all applicable electrical codes and proper wiring

procedures.

Caution:

In hazardous areas, do not power the unit until the conduit

is sealed and the enclosure cover is screwed down

securely.

7. Replace housing cover.

8. If control has been furnished with an explosion proof or

moisture proof (gasketed) switch housing, it must be

sealed at the conduit outlet with a suitable compound or

non-hardening sealant to prevent entrance of air.

9. Test switch action by varying liquid level in float chamber.

NOTE: If switch mechanism fails to function properly, check vertical

alignment of control housing and consult installation bulletin

for additional wiring information on switch mechanism

furnished. See

Section 6.1.2, Switch and Housing

Reference

on page 19.

10. Check cover to base fit to be certain gasketed joint is tight.

A positive seal is necessary to prevent infiltration of mois-

ture laden air or corrosive gasses into switch housings.

Internal Circuit

(Right) Switch

1

2

3

Load

Load

Close on high level

Close on low level

Line

4

5

6

Internal Circuit

(Left) Switch

Load

Load

Close on high level

Close on low level

Line

Common

Common

Figure 3

Wiring Diagram