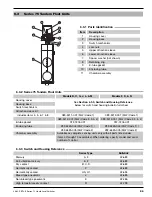

5

46-620 B73 & Series 75 Liquid Level Switche

s

2.4

Switch Differential Adjustment

The standard differential of Series 75 float models with

one switch may be field adjusted. Adjustment may be

necessary if a wider differential needs to be set to overcome

switch chatter caused by the process.

NOTE: This procedure may be applied to single switch models only.

The differential, or the amount of level travel between

switch-on and switch-off, may be adjusted by repositioning

the lower jam nuts on the float stem. This adjustment is

different for high level and low level controls. Refer to the

appropriate section below for adjustment instructions.

NOTE: Maximum differential adjustment is 1 inch.

Caution:

Differential adjustments should NOT be made in the field

on tandem float models. Switch actuation levels have

been set at the factory to meet customer specifications.

Variations in actual conditions from design conditions,

usually require special control modifications. Consult the

factory or your local representative for assistance.

2.4.1 Low Level Controls

On low level controls the switch trips on the lower

actuation point and resets on the higher actuation point.

Widening the differential will allow the switch to trip

on the original actuation point and reset at a later or

higher point.

The differential on low level controls may be adjusted by

repositioning the lower jam nuts on the float stem. The

standard factory setting is for a minimum amount of play

(gap) between the top jam nuts and the attraction sleeve.

Refer to

Figure 6

.

1. Determine what change in differential is necessary.

NOTE: To widen the differential by one inch, the lower jam nuts must

be set proportionately lower on the stem (i.e., in this example

by 1 inch).

2. Make sure power source is turned off.

3. Unscrew and remove switch housing cover.

4. Disconnect power supply wires from switch mechanism.

Pull wires out of conduit connection opening in housing

base. Refer to

Figure 8

.

5a. Perform system shut-down procedures as required to

relieve pressure from float chamber of control. Allow unit

to cool.

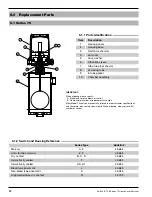

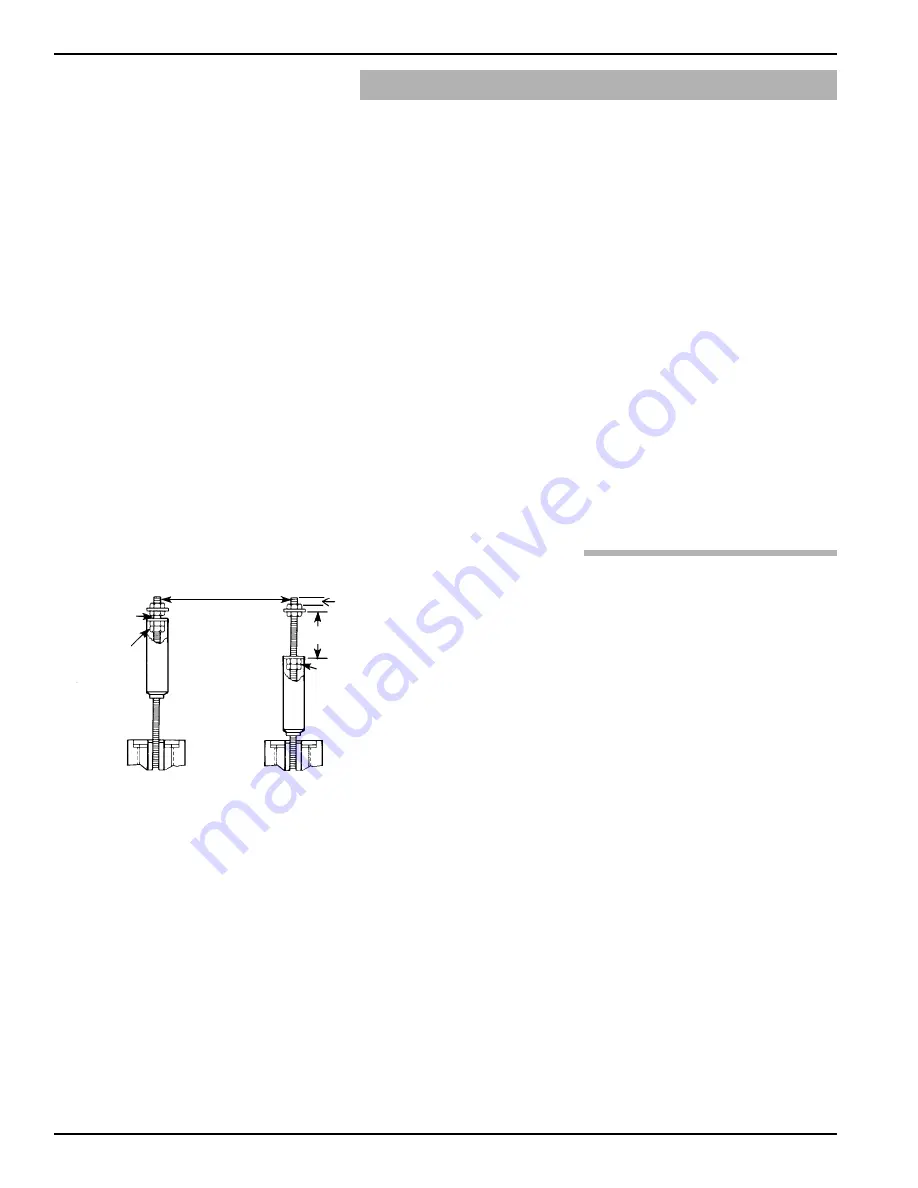

Figure 6

Figure 7

Slight play (gap)

Must be allowed

(0.03" typical)

Replace in same position

Position of bottom

jam nuts (normal

factory setting)

Maximum gap setting

(applies to models

having a single

switch mechanism

with a single magnet

actuator only)

Drop bottom

jam nuts to

increase gap

setting (refer

to above

instructions)

1.00 (25 mm)

D