3

INST

ALLATION

INSTALLATION LOCATION

Kotron transmitters should be located for easy access for

service, calibration and monitoring. Transmitters should not

be exposed to ambient temperatures below -40°C (-40°F) or

above +70°C (+160°F).

Special precaution should be made to prevent exposure

to corrosive atmosphere, excessive vibration, shock or

physical damage.

It is common practice to use the metal tank wall as the

reference electrode (refer to Operating Principle).

In such cases, it is required that the probe housing makes a

good electrical connection to the tank wall. If there is any

doubt about this connection due to the use of PTFE thread

tape, gaskets, paint, rust, or any other reason, a separate

strap should be installed between the probe housing and

the tank.

CAUTION:

This unit contains CMOS electronics

which may be damaged by static electricity. Do not

touch any semi-conductor devices unless you are

properly grounded.

MET

AL WALLED TANKS

On water based liquids, there should be no problem with

sensitivity or linearity. With non-conductive, low dielectric

media, sensitivity can be enhanced by locating the

probe close to and parallel with the tank wall. If this is

not practical, a concentric ground tube, sometimes called

a stilling well, may be a solution.

NOTE

: These comments are true for glass-lined metal

walled

tanks also.

T

anks/Silos –

with non-conductive materials of construction

W

ith plastic, concrete, wood, or any other non-conductive

walled vessels, the reference electrode mentioned in the

“Operating Principle” section on page 1 needs clarification.

Most commonly, this electrode will be in the form of a

concentric ground tube (i.e. stilling well). Refer to

Figure 1.

In questionable circumstances, consult the Factory

. In all

cases, a good electrical connection must be made between

the ground surface and the probe housing.

MOUNTING

T

wo-wire transmitters with probes up to and including

305 mm (12") in length are shipped pre-assembled. Two-

wire transmitters with probes over 305 mm (12") in length

are shipped unassembled to avoid damage during transit.

They must be assembled before mounting. Follow the

mounting procedure for your particular case.

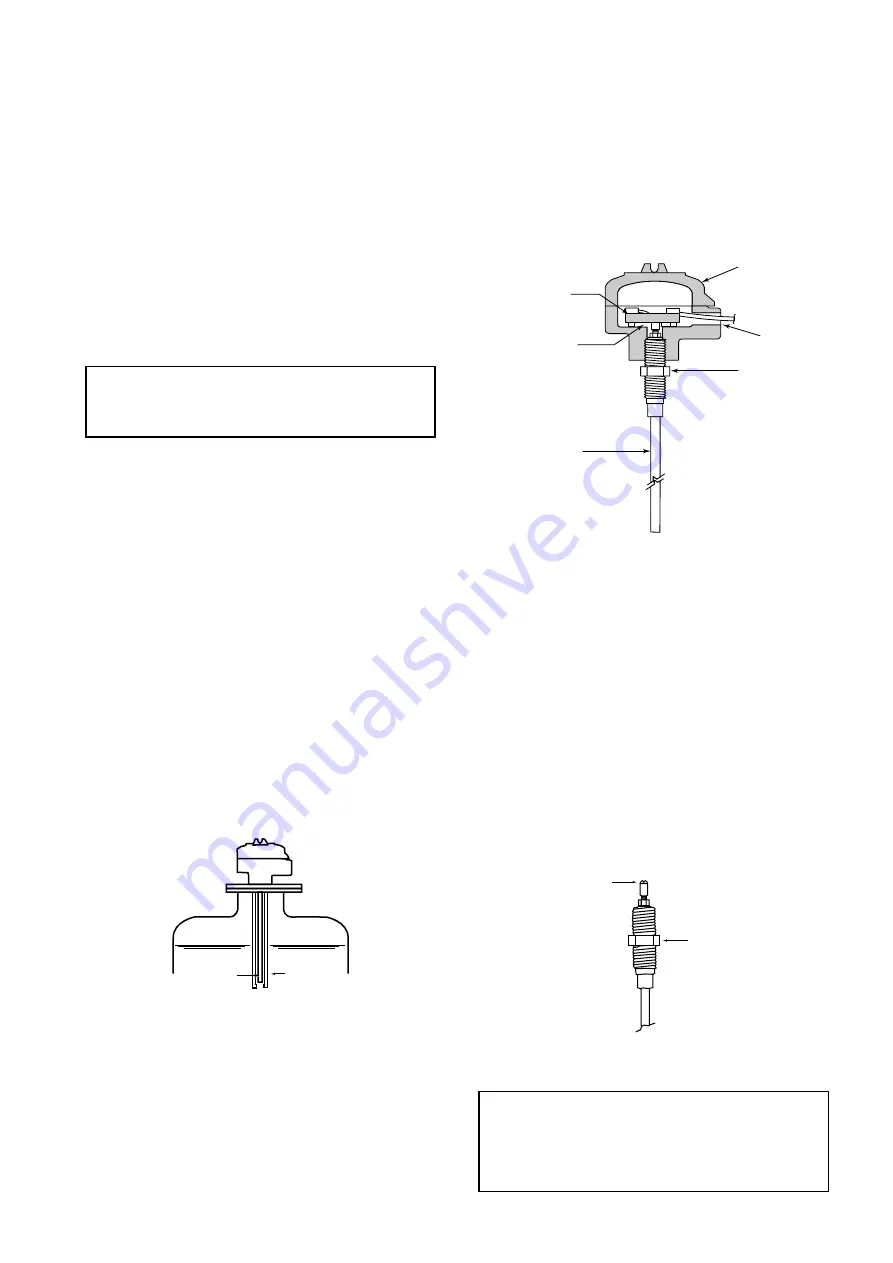

MOUNTING PROCEDURE A

Pre-assembled transmitters,

integral mount with rigid probe

1.

Thread transmitter assembly into mounting bushing on

tank.

2. Tighten securely, being certain that the wrench is applied

ONL

Y

to the packing gland nut. See

Figure 2

.

3. Proceed to Wiring instructions

on page 5.

MOUNTING PROCEDURE B

Unassembled transmitters,

integral mount with rigid probe

1.

Thread probe into mounting bushing on tank.

2. Tighten securely, being certain that the wrench is

applied

ONL

Y

to the packing gland nut. See

Figure 3

.

3. Screw the transmitter/probe housing onto the probe.

See

Figure 3

. Do not pinch or cut the packing gland.

4. Screw housing on probe until hand tight. Housing can be

wrench tightened to align electrical connection. See

Figure 2

.

5. Remove housing cover.

6. Locate the white wire, which is fastened to the (+) Probe

Terminal. Connect the free end of this wire to the probe

connection screw.

7. Proceed to the "WIRING INSTRUCTIONS" on page 5.

CAUTION:

Packing glands used on all Magnetrol

rigid probe assemblies have been sealed at the

factory under controlled conditions. Care must be

exercised when installing probe assemblies to

avoid breaking pressure tight gland seal, which

destroys the seal.

;

;

;;

Figure 1

Figure 2

Integral mount models with rigid probe

Figure 3 –

Threaded probe

Probe connection screw

Packing gland nut

(when installing, use wrench

on this nut only)

Probe

Concentric

ground tube

Probe

terminal

PC board

Packing

gland nut

Transmitter

housing

Electrical

entry

Rigid probe