6

CALIBRA

TION

AUXILIARY CURRENT METER

In order to calibrate the transmitter

, you may use either the

loop current meter, or a second current meter which has an

internal resistance of less than 10 Ω.

It should read currents in the range of 1 to 25 mA, with a

resolution of 0.01 mA. Using a meter of less resolution will

somewhat reduce the calibration accuracy.

An error of 0.2 mA is equivalent to a 1% error, based on the

full scale current of 20 mA.

To calibrate the instrument:

1. Remove transmitter housing cover.

2. Check that the LED is glowing (shadowing the LED by

hand may be helpful in brightly lit environments).

NOTE

: The LED will glow brighter with increasing signal.

a. If the LED is lit, continue to step 3.

b. If the LED isn’t lit, check for supply voltage of 14 to

40 V at the terminal strip. Also confirm that the

polarity is correct. If LED still does not light, replace

the cover and contact factory.

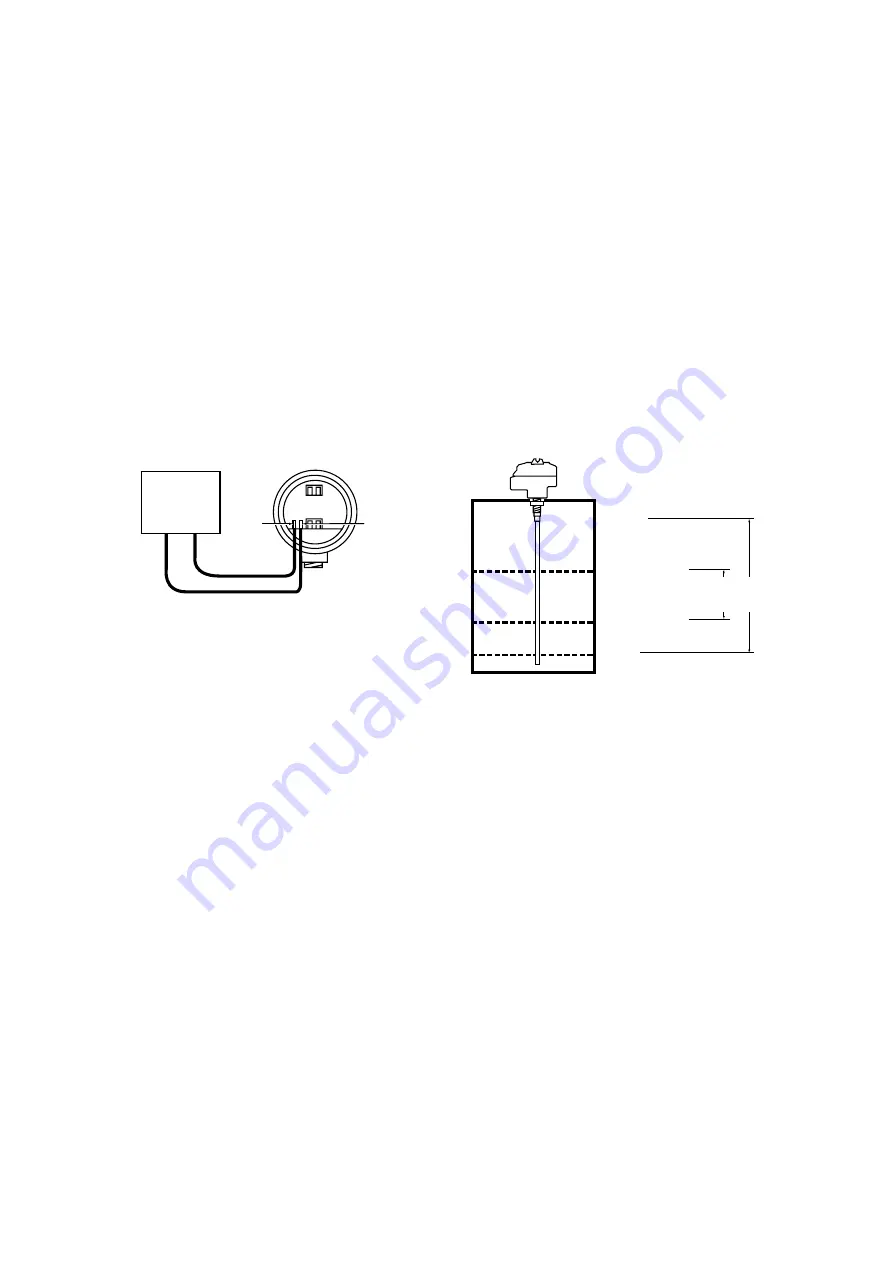

3. Connect the auxiliary meter’s positive lead to Test point

1 and its negative lead to Test point 2. See

Figure 7

.

NOTE

: This use of TP- and TP+ allows the loop current to

be monitored at the location where the adjustments are

being made, without removing any wires.

It is not necessary to use this auxiliary meter if another

means is available to measure loop current.

a. If the LED goes completely out, proceed to step 4.

b. If the LED doesn’t go out, check the following:

• the meter is properly connected.

• the appropriate meter range has been selected.

• meter resistance is less than 10 Ω for the

selected range.

4. The loop current should now be in the range of 1.5 mA

to 38 mA, which is normal at this point.

TWO POINT CALIBRA

TION - LEVEL INCREASE

T

wo calibration procedures are described on page 7. Follow

the one which fits your application.

Please note the following definitions used in the calibration

procedures, referring to

Figure 8

.

L0 =

the level of material in the vessel which corresponds

to 4.0 mA of loop current, i.e., the 0% level.

L1 =

a material level higher than L0.

L2 =

a material level higher than L1, but less than L3.

L3 =

the level of material in the vessel which corresponds

to 20.0 mA of loop current, i.e., the 100% level.

NOTE

: T

o avoid the possibility of a “dead zone”, L0 must

be at least 50 mm (2") above the end of the probe for

conductive media and 100 mm (4") above for non-

conductive media.

Calibration A = when material in tank can be set to L0 (0%)

and L3 (100%).

Calibration B = when material in tank can be set to L1

(greater than 0%) and L2 (less than 100%).

NOTE

: Calibration Procedure A gives the most accurate

results and is the recommended procedure in all cases.

+

TP +

-

TP -

B

A

Figure 8

Figure 7

Auxiliary

current

meter

L3 - 100 %

L2 - less than 100 %

L1 - greater than 0 %

L0 - 0 %

Calibration

procedure