7

CALIBRA

TION (cont.)

CALIBRATION PROCEDURE B

1.

Set the material level in the vessel to L1, some point

above 0%. Record the L1 level in mm, cm, inches, feet

or percent of span.

2. Turn the coarse zero

➀

, zero fi

ne

➁

and the fi

ne span

➂

calibration controls clockwise (CW) twenty full turns or

until ratcheting is heard. Set all the coarse span DIP

switches in their OPEN (down) position

➃

.

Ensure that the ZERO dip switches 2 and 3 are in open

position and ZERO dip switch 1 is in closed position

➄

.

See

Figure 9

.

3. To determine the correct output level at this point, use

the following formula:

L

1

mA

=

(

(

L

1 -

L

0

)

x 16) + 4

(

L

3 -

L

0)

4. Turn the Zero Coarse potentiometer counterclockwise

until the loop output is between L1

mA

and L1

mA

+

0.5 mA.

5. If the loop current output cannot be decreased to at least

L1

mA

+ 0.5 mA, turn the Zero Coarse potentiometer fully

clockwise, close Zero Coarse DIP switch positions

“Med” and “High” sequentially (ONLY ONE SWITCH

POSITION SHOULD BE CLOSED AT A TIME—THE

OTHER TWO POSITIONS MUST REMAIN OPEN).

Repeat Step 4.

6. Turn potentiometer Zero Fine counterclockwise until the

loop output reads exactly L1

mA

.

7. Move the media level in the vessel to the highest level

you can set.

8. To determine the correct output level at this point, use

the following formula:

L

2

mA

=

(

(

L

2 -

L

0

)

x 16) + 4

(

L

3 -

L

0)

9. In sequence, individually close Span Coarse DIP switch-

es “Low”, “Med”, and “High”, until the loop current is as

close to (and not less than), L2

mA

. (ONLY ONE SWITCH

POSITION SHOULD BE CLOSED AT A TIME—THE

OTHER TWO POSITIONS MUST REMAIN OPEN).

10. Turn the Span Fine potentiometer counterclockwise until

the loop current is exactly L2

mA.

Calibration is now complete.

CALIBRA

TION PROCEDURE A

1.

Move the material in the vessel to its L0 (0%) level.

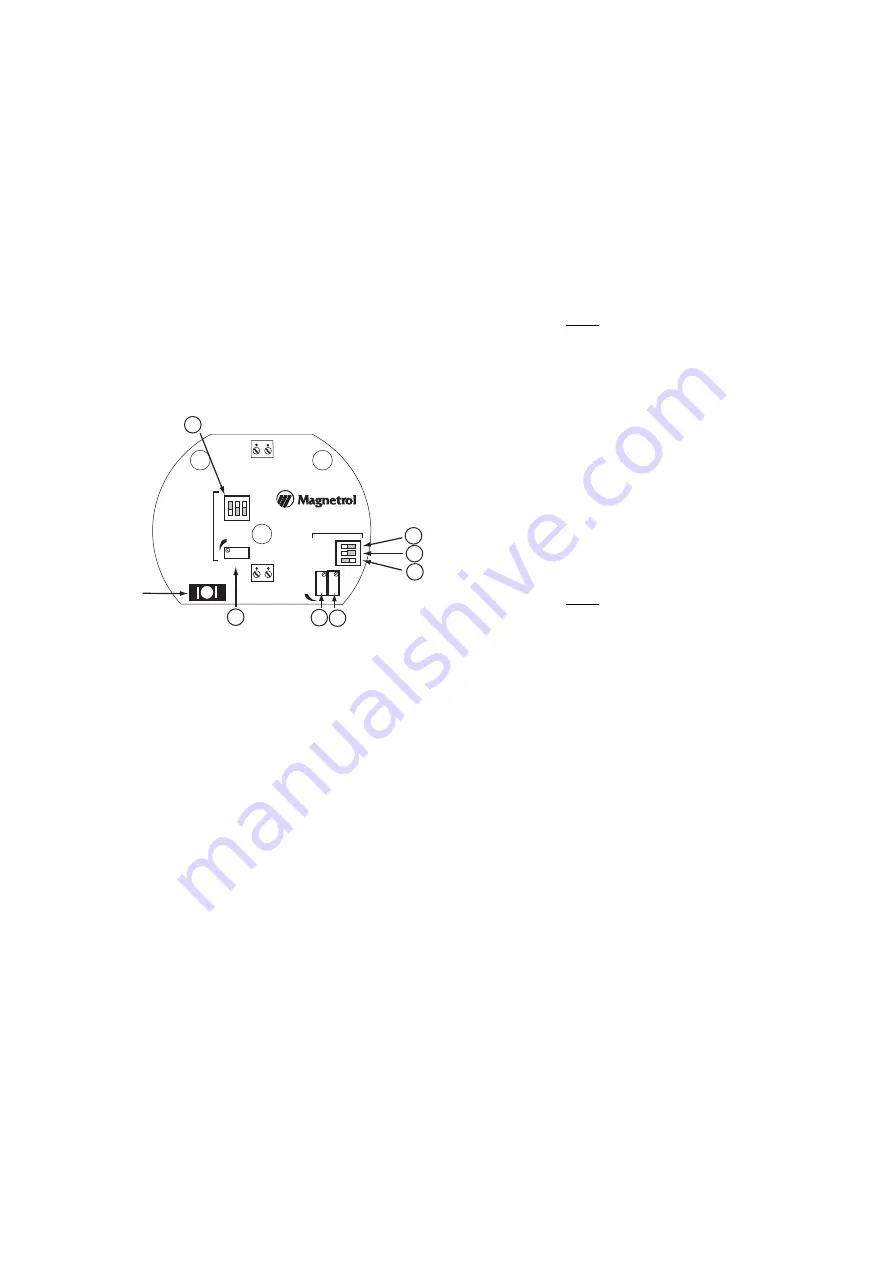

2. Turn the zero coarse

➀

, zero fi

ne

➁

and the fi

ne span

➂

calibration controls clockwise (CW) twenty full turns or

until ratcheting is heard. Set all the coarse span DIP

switches in their OPEN (down) position

➃

.

Ensure that the ZERO dip switches 2 and 3 are in open

position and ZERO dip switch 1 is in closed position

➄

.

3. Turn the coarse zero control

➀

CCW until the meter

reads close to 4 mA without going under.

4. If the loop current can not be decreased to at least

4.50 mA, turn the Zero Coarse potentiometer fully clock-

wise, close DIP switch positions “Med” and “High”

sequentially (ONLY ONE SWITCH POSITION SHOULD

BE CLOSED AT A TIME – THE OTHER TWO POSI-

TIONS MUST REMAIN OPEN). Repeat Step 3.

5. Turn potentiometer Zero Fine

➁

counterclockwise until

the loop output reads exactly 4.00 mA.

6. Fill the vessel to the desired L3 (100%) level. Ensure

that the SPAN DIP switches are still in open position.

NOTE:

The loop current may not rise in proportion to the

rising material level in the vessel. Instead, the loop current

may rise rapidly ahead of the material level.

7. After the vessel has been filled to L3 (100%), in

sequence, individually move SPAN COARSE

➃

DIP

switches 1, 2 and 3 to the CLOSED (up) position until

the current output is as close to 20 mA as possible with-

out going under. Only one DIP switch should be

CLOSED at any time - the others are to remain OPEN

(down).

8. Turn the span fine

➂

calibration control CCW until the

meter reads exactly 20 mA. Calibration is now complete.

+ –

POWER

30-9012-001

+ –

PROBE

COARSE

1 2 3

– OPEN –

1 2 3

– OPEN –

5a

5b

5c

4

3

1

2

SPAN

FINE

COARSE

HIGH

MED

LOW

L

O

W

M

E

D

H

I

G

H

FINE

ZERO

Figure 9

4-20 mA

test points