F E A T U R E S

•

Multivariable two-wire, 24 VDC loop-powered

transmitter for level or volume

•

Performance not process dependent (changing

specific gravity and dielectric have no effect)

•

6 GHz operating frequency offers superior perform-

ance in the tougher applications with turbulence,

foam, and heavy vapors

•

Echo Rejection setup is simple, intuitive and effective

•

Antenna designs to +400°F (+200°C),

-14.7 to 750 psig (-1.0 to 51.7 bar)

•

Range up to 130 feet (40 meters)

•

Quick connect/disconnect antenna coupling allows

vessel to remain sealed

•

Extremely low output at antenna: < .01 mW (avg),

< 2 mW (max); hundreds of times less than a cell

phone

•

4-button keypad and graphic LCD display allow for

convenient viewing of configuration parameters and

echo curve

•

Proactive diagnostics advise not only what is wrong,

but also offer troubleshooting tips

•

Available for use in SIL 2 Loops (92.7% SFF, with full

FMEDA report available

•

PACT

ware

™

PC Program and enhanced DTMs for

advanced configuration and troubleshooting

•

Available with HART

®

or F

OUNDATION

fieldbus

™

digital

output

D E S C R I P T I O N

The Pulsar

®

R96 Radar transmitter is the latest

generation of Magnetrol

®

24 VDC, loop-powered, non-

contact radar transmitters. Enhanced performance and

innovative diagnostics bring simplicity to an often

complicated technology.

This latest entry into the radar level measurement field

is designed to provide unparalleled performance and

ease of use. PULSAR non-contact radar is the perfect

compliment to the MAGNETROL Eclipse

®

Model 706

Guided Wave Radar transmitter. Together, these trans-

mitters offer the ultimate solution to the vast majority of

process level applications.

T E C H N O L O G Y

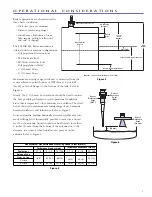

The PULSAR Radar transmitter is based on pulse burst

radar technology combined with equivalent time sam-

pling circuitry. Short bursts of 6 GHz microwave energy

are emitted and subsequently reflected from the liquid

level surface. Distance is calculated by the equation

D = Transit time (round-trip)/2

. Liquid level is then

calculated by applying the tank height value.

A P P L I C A T I O N S

MEDIA:

Liquids and slurries; hydrocarbons to water-

based media (dielectric 1.7–100)

VESSELS:

Most metal and concrete process or storage

vessels up to rated temperature and pressure. Pits and

sumps as well as glass-lined tanks.

CONDITIONS:

Virtually all level measurement and

control applications including process conditions

exhibiting varying specific gravity and dielectric,

visible vapors, high fill/empty rates, turbulence, low

to moderate foam and buildup.

Pulsar

®

Model R96

Pulse Burst Radar

Level Transmitter