10

54-610 Thermatel Model TD1/TD2 Flow Level Switch

2.6.1.1

Unable to Change Level

•

Low Level:

Follow the procedures in Step 5b, steps a–e on

page 9. Any change in media will cause a low level alarm

indication.

•

High Level:

1. Ensure that the sensor is located above the level of the

fluid.

2. Set Fail-safe to the “HL” position (

).

3. Turn alarm potentiometer counterclockwise until the red

LED goes on.

4. Turn alarm potentiometer clockwise until red LED goes

off. If unable to get the red LED to turn off, change the

HTR position to “–”.

5. Repeat steps 3 and 4 several times leaving the red LED off.

Turn potentiometer

1

⁄

2

additional turn clockwise.

6. Any change in media will cause the switch to go into alarm.

NOTE: The time to reset may be lengthy. This time can be decreased

by turning the potentiometer clockwise.

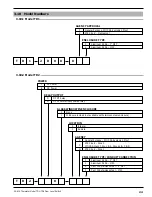

2.6.2 Adjustment Procedure LOW FLOW/NO FLOW

1. Put HTR Switch in the "+" position (

).

2. Place Fail-safe in the “LL” position (

).

3. Reduce the flow rate to the desired alarm point. Allow 3

minutes for the sensor to stabilize.

4. Rotate alarm potentiometer clockwise until the red LED

turns off.

5. Rotate alarm potentiometer counterclockwise until the red

LED turns on.

6. Repeat steps 4 and 5 several times leaving the red LED in

the "on" position.

7. Resume full flow. The alarm should reset.

8. Reduce flow to no flow or the desired alarm point. If the

response time required to alarm is too long, rotate alarm

potentiometer counterclockwise

1

⁄

2

turn and test again.

9. If the response time required to sense flow is too long,

rotate the alarm potentiometer clockwise

1

⁄

2

turn and

test again.

10. Repeat steps 8 and 9 until desired response times for flow

and no flow are attained. Normal delays range from two

seconds to over fifteen seconds, depending on the fluid

and the flow rate.

Low Flow Adjustment

(Low Level Fail-safe)

Faster response to

low flow or decrease

alarm point

Faster response to

reset or increase

alarm point

Turn

Turn