1.0

Installation

This section provides detailed procedures for properly

installing the Model TK1 Liquid Level Switch.

Caution:

If equipment is used in a manner not specified by

manufacturer, protection provided by equipment may be

impaired.

1.1

Unpacking

Unpack the instrument carefully. Inspect all units for dam-

age. Report any concealed damage to the carrier within 24

hours. Ensure that all components have been removed from

the packing material. Check all contents against the packing

list and report any discrepancies to the factory. Check the

nameplate model number to ensure that it corresponds with

the packing slip and purchase order. Record the serial and

model numbers for future reference when ordering parts.

Model Number

Serial Number

1.2

Before You Begin

Caution:

During the installation of Model TK1, the float and pivot

area must be kept free of metallic particles that might be

attracted to the magnet.

Caution:

This instrument is intended for use in Installation Category

II

,

Pollution Degree 2.

1.2.1 Site Preparation

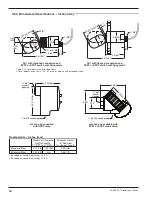

1. Ensure that the length and the inside diameter of the

mounting nozzle are sized correctly for the Model TK1.

See dimensional information on page 10 for requirements.

2. Ensure that the mounting nozzle, coupling or flange is

within 3° of horizontal. If mounting the TK1 in an external

cage, ensure that the top/bottom piping is within 3° of ver-

tical in all directions.

1.2.2 Equipment and Tools

No special equipment or tools are required to install the

Model TK1 Liquid Level Switch. The following items are

recommended:

• Wrenches, gaskets and/or bolting as appropriate for the

process connection.

• Pipe wrench

• Level

44-608 TK1 Liquid Level Switch

3