44-608 TK1 Liquid Level Switch

1.3

Mounting

The Model TK1 Liquid Level Switch is available with a

1

1

⁄

2

" or 2" threaded mounting bushing as well as several

flange mountings.

1.3.1 Threaded Mounting

Apply either Teflon

®

tape or appropriate lubricant to

mounting threads to prevent galling. Engage thread by hand

to avoid damage. Using a pipe wrench, rotate the unit

clockwise until threads are tight in mounting. Ensure that

the N.O. marking on body is upward for normally opened

operation on models with SPST switches. For normally

closed operation, ensure that the N.C. marking is upward.

Models with SPDT or DPDT switches should be mounted

with the N.O. marking upward.

1.3.2 Flanged Mounting

Have proper flange bolting and gasket(s) on hand. Carefully

align the bolt holes of the TK1 flange with those of the

vessel mounting flange. Ensure that the N.O. marking on

body is upward for normally opened operation on models

with SPST switches. For normally closed operation, ensure

that the N.C. marking is upward. Models with SPDT or

DPDT switches should be mounted with the N.O. marking

upward. Ensure that the flange gasket is seated properly.

Install flange bolting.

Caution:

Operation of all buoyancy type level devices should be done

in such a way as to minimize the action of dynamic forces on

the float or displacer sensing element. Good practice for

reducing the likelihood of damage to the control is to equal-

ize pressure across the device very slowly.

1.4

Wiring

NOTE: A switch or circuit breaker shall be installed in close proximity to

equipment and within easy reach of operator. It shall be marked

as the disconnecting device for the equipment.

NOTE: For supply connections in installations with ambient tempera-

ture up to +70° C, use wire with a minimum rating of 75° C as

required by the process conditions. Installations with ambient

temperatures up to +80° C require wire with a minimum rating

of 85° C as required by the process conditions. Use a minimum

of 14 AWG wire for power and ground field wires.

1. SPST reed switch: Switch action is determined by the orien-

tation of the TK1. For actuation on rising level, ensure that

the TK1 is positioned so that the N.O. marking is on top.

For actuation on falling level, ensure that the TK1 is posi-

tioned with the N.C. marking on top.

Connect wiring to terminals per the wiring diagram in

Figure 1.

Connect wiring to the flying leads per wiring diagram

in Figure 2 when mounted in N.O. position, and as in

Figure 3 when mounted in N.C. position.

4

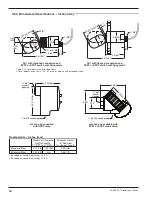

Figure 1

SPST wiring diagram

terminal housing

Figure 4

SPDT wiring diagram

terminal housing

Figure 2

SPST wiring N.O. position flying leads

to switch

to switch

NO

NC

not used

C

to switch

Red

Green

Red

Figure 3

SPST wiring for N.C. position flying leads

Green

Red

Red