3.0

Reference Information

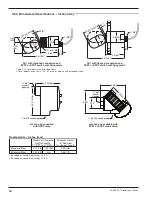

This section presents an overview of the operation of the

Model TK1 Liquid Level Switches, including information

on troubleshooting common problems, maintenance proce-

dures, listings of agency approvals, and detailed physical,

functional, and performance specifications.

3.1

Description

The Model TK1 Liquid Level Switches are float actuated

devices designed for horizontal mounting in a tank or

process vessel through threaded or flanged connections. This

low cost switch is ideal for OEM applications where a single

point high or low level alarm is desired.

3.2

Theory of Operation

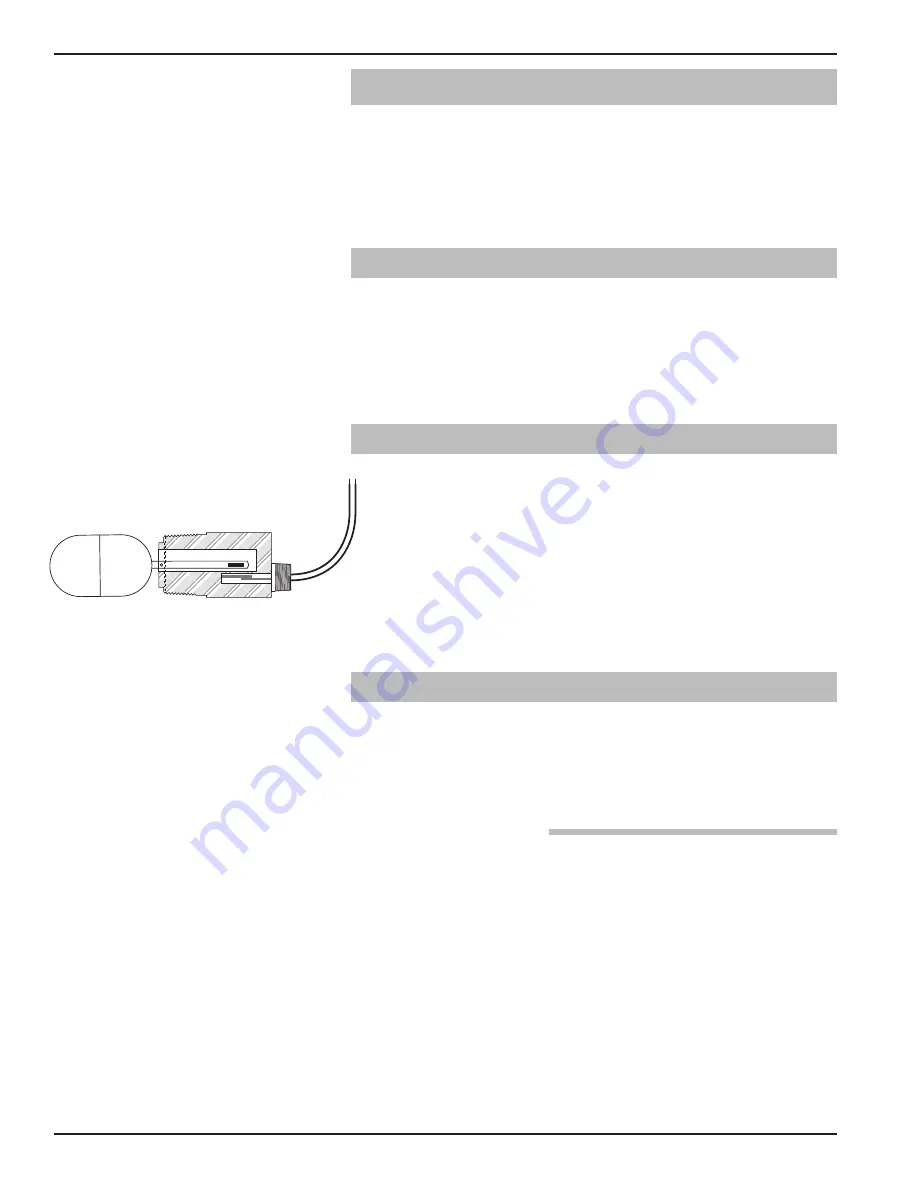

Switching action is achieved through the use of a magnet

attached to the float assembly and its interaction with a

switch mechanism. Separating the float magnet and the

switch is a non-magnetic pressure barrier.

As the liquid level changes, the float along with the float

magnet moves. The magnetic field of the float magnet

causes a change of state of the switch, making or breaking

an electrical circuit.

3.3

Troubleshooting

The Model TK1 Liquid Level Switch is designed and engi-

neered for trouble-free operation. Common problems are

discussed in terms of their symptoms and corrective actions

as recommended.

3.3.1 External Causes

Usually the first indication of improper operation is failure

of the controlled equipment to function (e.g., pump will

not start (or stop), signal lamps fail to light, etc). When

these symptoms occur, whether at the time of installation or

during routine service thereafter, check for the following

potential external causes first:

• Blown fuses

• Tripped reset button(s)

• Open power switch

• Faulty equipment controlled by level switch

• Defective wiring to level switch

44-608 TK1 Liquid Level Switch

6

Figure 7

Cross section