INSTRUCTIONS FOR USE AND WARNINGS

11

Only transport loads that are properly balanced;

The equipment must be lowered to the ground in

a hazard-free area devoid of obstacles;

The empty hook must be lowered gently, to prevent

abnormal stresses on the rope which can damage the

rope itself or the equipment structure;

Never leave the forklift truck parked with a raised

load;

The operator must stop using the vehicle if visibility

and lighting conditions are poor;

While working at heights, check constantly to make

sure the wind speed never exceeds 45 km/h (28 mph).

In case of strong wind, retract the equipment

immediately, as the specific wind pressure on hanging

loads can overload the forklift truck and affect its

stability;

Avoid using the equipment in especially adverse

weather conditions (rain storms in the presence of

lightning);

The forklift truck, carrying equipment fitted with

ropes, must be inspected periodically as envisaged

for lifting equipment, in compliance with legislation,

provisions and regulations applicable in the country

of use. The user alone is responsible for ensuring

compliance with the legislation in force;

Before starting work with the equipment or other

lifting equipment with hook, inform the authorities

responsible for inspections in your area;

Request the body responsible in the country of

operation for yearly inspections.

How to hook the equipment

Potential risks in the following operations:

crushing and injury to the upper limbs.

•

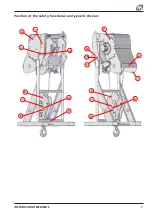

position the equipment on

a stable level surface;

•

bring the forklift truck near

the equipment, positioning

the end part of the boom

with the quick-fit coupling

retracted suitably to fit it in

the hooking seat;

•

fit the equipment with the

boom head quick-fit coupling;

•

tilt the boom head coupling

round to the equipment

frame to insert the shear pin;

•

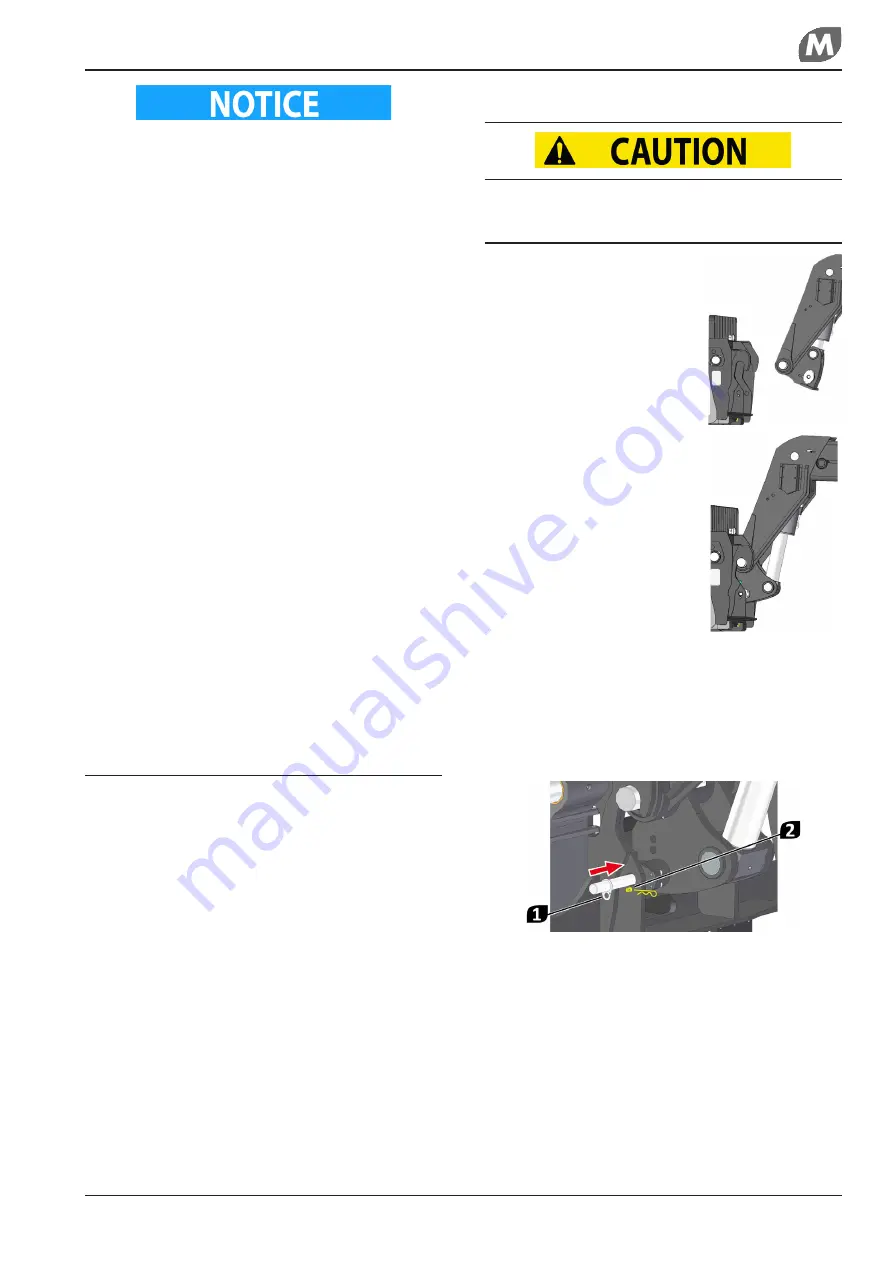

insert the retainer pin

1

into the hole present on

the connecting flange of the boom aligned with the

hole present on the equipment hooking structure;

•

insert the split shear pin

2

in the hole present

on the pin which is integral with the equipment

structure in such a manner as to prevent it from

coming loose;

•

connect the hydraulic system of the equipment

to the connectors on the head of the vehicle’s

telescopic boom [when present];

•

connect the electrical system of the equipment

to the connectors on the head of the vehicle’s

telescopic boom [when present].

Vehicles produced by Magni T.H. are equipped with

identification software that recognises the equipment

connected and which enables movements and specific

safety systems according to the type of equipment

connected.