©

2013 Magnum Energy, Inc.

Page 44

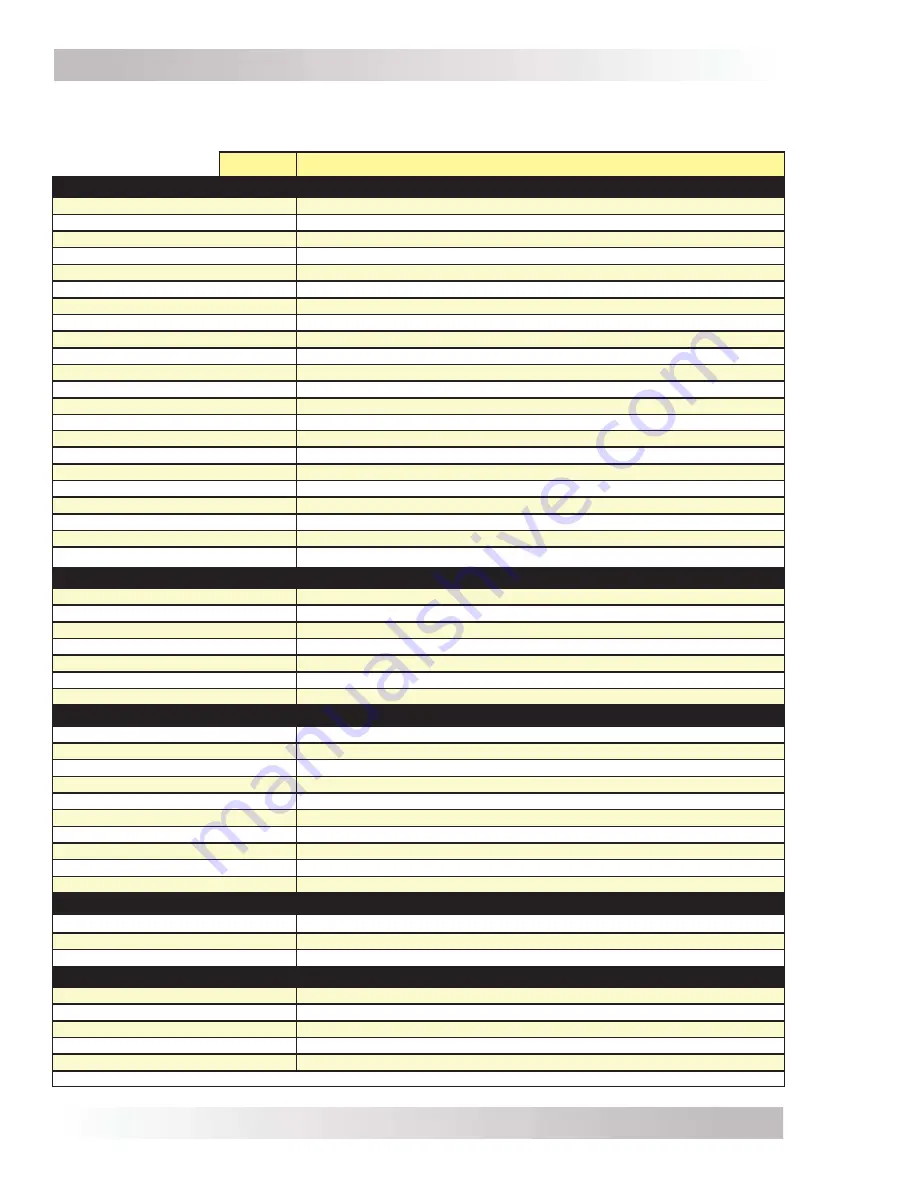

Appendix A – Specifi cations

Model

MSH4024RE

Inverter Specifi cations

Input battery voltage range

18.0 to 34.0 VDC

Absolute maximum DC input

35 VDC

AC output voltage accuracy

120 VAC ±3% (

≤

continuous power)

Output frequency and accuracy

60 Hz ± 0.05 Hz

Total Harmonic Distortion (THD)

< 5%

Continuous power output (at 25°C)

4000 VA

Continuous AC output current

33 A

1 msec surge current (amps AC)

120

100 msec surge current (amps AC)

72

5 sec surge power (real watts)

5800

30 sec surge power (real watts)

5400

5 min surge power (real watts)

4900

30 min surge power (real watts)

4500

Maximum continuous input current

267 ADC

Inverter ef

fi

ciency (peak)

93.7%

HBCO/HBCI (High Battery Cut Out/In)

33.6 VDC/33.0 VDC

LBCO/LBCI (Low Battery Cut Out/In)

18.0 VDC (adj)/25.0 VDC

Inverter stacking (series or parallel)

No

AC relay transfer time (minimum)

<16 msec

Power consumption – searching

<7 watts

Power consumption – inverting (no load)

25 watts

Output waveform

Pure Sine Wave

Charger Specifi cations

Continuous charger output at 25°C

110 ADC

Input current for continuous rated output

29 AAC

Maximum current during load support

160 ADC

Charger ef

fi

ciency

85%

AC input frequency range

50 to 70 Hz

AC input voltage range

60 to 140 VAC (120 VAC nominal)

Power factor

> 0.95

General Features and Capabilities

Transfer relay capability

60 AAC maximum each input

Five-stage charging capability

Bulk, Absorb, Float, Equalize (requires remote), and Battery Saver™

Battery temperature compensation

Standard with available temp sensor connected (battery temp 0-50 °C)

Internal cooling

0 to 120 cfm variable speed drive using dual 92 mm brushless DC fan

Overcurrent protection

with two overlapping circuits

Over-temperature protection

on transformer, MOSFETS, and battery

Corrosion protection

PCB’s conformal coated, powder coated chassis/top, and stainless steel fasteners

Safety listings

ETL listed to UL/cUL 1741, CSA C22.2 No. 107.1-01

Warranty

3 years parts and labor

Branch-rated output circuit breakers

No

Environmental Specifi cations

Operating temperature

-20°C to +60°C (-4°F to 140°F)

Non-operating temperature

-40°C to +70°C (-40°F to 158°F)

Operating humidity

0 to 95% RH non-condensing

Physical Specifi cations

Unit dimensions (length x width x height)

13.75” x 12.65” x 8.0” (34.9 cm x 32.1 cm x 20.3 cm)

Shipping dimensions (l x w x h)

19.0” x 17.0” x 13.0” (48.3 cm x 43.2 cm x 33.0 cm)

Mounting

Shelf or wall (vents not allowed to face downward unless ME-CB or MMP is installed)

Weight

Unit: 58 lb (26.3 kg) / Shipping: 60 lb (27.2 kg)

Max operating altitude

15,000 ft (4570 m)

Speci

fi

cations @ 25°C – Subject to change without notice.

Appendix A – Specifi cations and Optional Equipment

A-1 Inverter/Charger

Specifi cations