11

BASIC CONTROLS

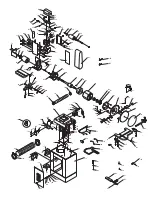

MAGNUM INDUSTRIA

L

BELT and DISC SANDER

MITRE GAUGE

The mitre gauge provides support when sanding straight (90°)

or angled ends (0° to 30°), making sanding safer and easier.

Both tables have slots for the mitre gauge.

To set the mitre gauge to an angle other than 90°, loosen

the

HANDLE (B)

by turning it counter-clockwise. Rotate the

MITRE HEAD (A)

to your desired angle as indicated on the

scale. Then tighten the

HANDLE (B)

by turning it clockwise.

See Figure 24.

CENTRE POINT

The sander includes a

CENTRE POINT (C)

for sanding circular

workpieces. See Figures 25 and 26.

It fits into the

MITRE SLOT (D)

perpendicular to the sanding

disc. Follow these steps to use the

CENTRE POINT:

1. Position the

CENTRE POINT

in the

MITRE SLOT

at a

distance that matches the radius of the workpiece.

2. Using the supplied 3 mm Allen key, secure the

CENTRE

POINT

in position by tightening the

SET SCREW (E)

.

3. Place the centre of the workpiece on the centre point’s

PIN (F)

.

4. Turn the sander on, and manually rotate the workpiece

against the sanding disc until you achieve the desired

results.

MAINTENANCE

Before performing any maintenance, make sure the sander is

turned OFF and unplugged from the power source.

•

Keep the machine clean. Vacuum or brush off any loose

debris and wipe down the machine and the tables

occasionally with a damp rag.

•

Keep the rollers clean. Dirt on rollers will cause poor

tracking and belt slippage.

•

Periodically inspect the ON/OFF switch, power cord, plug

and other parts for damage.

•

Do not operate the sander with a damaged switch,

power cord, plug, or other parts. Replace damaged parts

immediately.

25

26

FIGURE 24: MITRE GAUGE

FIGURE 25: CENTRE POINT

FIGURE 26: CENTRE POINT PLACEMENT

24