12

C

A

D

Adjustments

Handwheel Adjustments

B

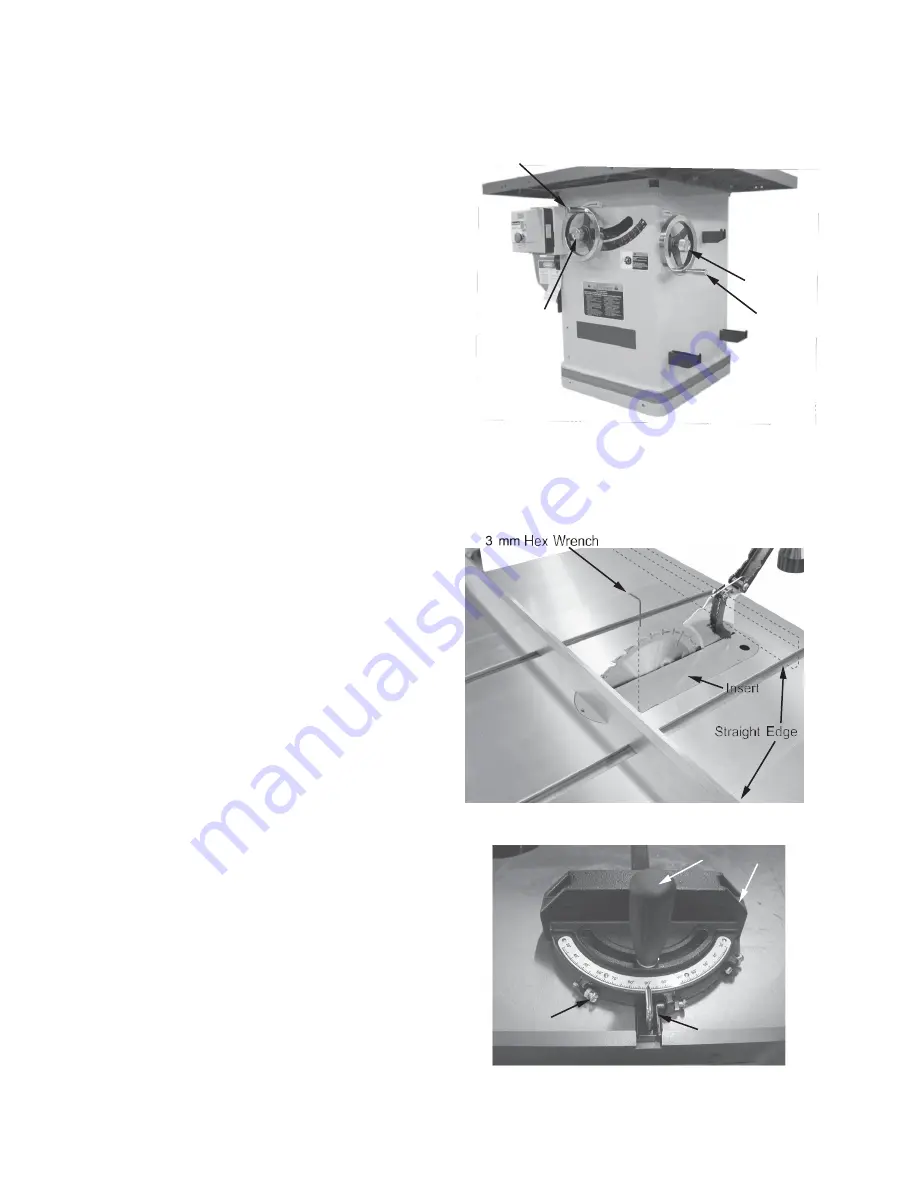

Referring to Figure 10:

The

front handwheel

(B) controls the raising and

lowering of the blade (blade height).

The

side handwheel

(D) controls the blade tilt. The

blade can be adjusted for a tilt between 90º

(vertical or a setting of 0º on the scale) and 45º left

tilt (D).

Blade height

1. Loosen the

lock knob

(A) on the

front

handwheel

(B).

2. Turn the

handwheel

(B) clockwise to raise and

counterclockwise to lower the blade.

3. Tighten the

lock knob

(A).

Blade tilt adjustment

1. Loosen the

lock knob

(C) on the side

handwheel (D).

2. Turn the

handwheel

(D) counterclockwise to

adjust the saw blade down to 45º

OHIW

tilt.Turn

clockwise to adjust the saw blade to maximum

of 90º.

3. After selecting the position, tighten the

lock

knob

(C).

Insert Adjustment

Adjust the setscrews in the insert with a 3mm hex

wrench (Figure 11) to ensure that the insert is

stable and flush with the table top.

Figure 10

Figure 11

Miter Gauge

Referring to Figure 12:

1. Operate miter gauge by loosening the

lock

knob

(A) and turning the

miter body

(B) to the

desired angle. To move gauge beyond index

stops of 45 and 90 , flip down the

stop

(C).

2. Adjust index stops by turning one of three

adjustment screws (D).

Note:

Always make test cuts. Do not rely solely on

miter gauge indicator marks. There are holes in the

miter gauge body that will allow you to mount a

wooden extension fence.

Figure 12

A

B

D

C

Summary of Contents for MI-51350

Page 1: ...MODEL NO MI 51350 MI 51453 OPERATING MANUAL...

Page 8: ...8 G H J H C A...

Page 18: ...18 Table and Cabinet Assembly Flat FrontType...

Page 21: ...21 Motor and Trunnion Assembly Breakdown Left tilt...

Page 26: ...26 Blade Guard Assembly...

Page 28: ...28 Wiring Diagrams 3HP 230V 1Phase A1 A2...