17

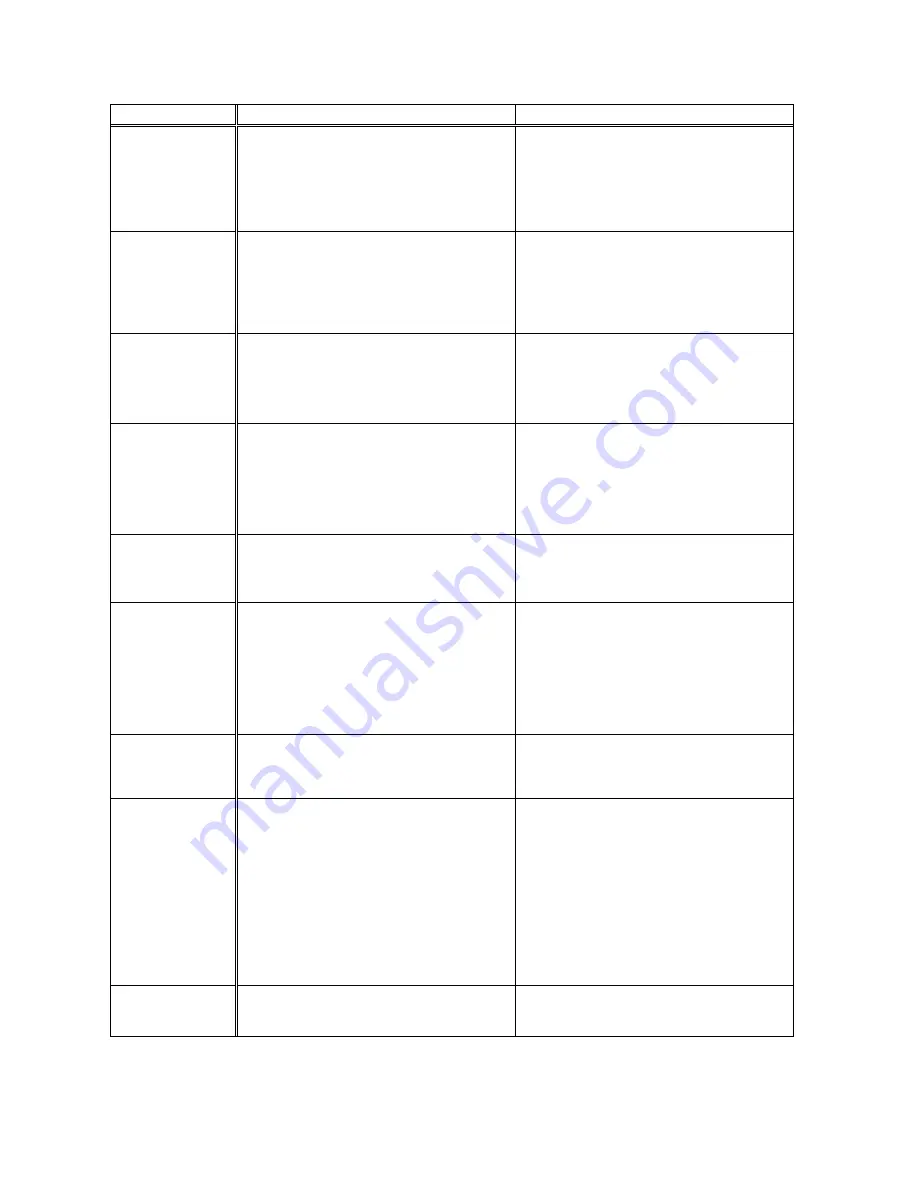

Troubleshooting

Trouble

Possible Cause

Solution

Saw stops or will

not start

Overload tripped

Saw unplugged from wall or motor

Fuse blown or circuit breaker tripped

Cord damaged

Allow motor to cool and reset by

pushing off switch

Check all plug connections

Replace fuse or reset circuit breaker

Replace cord

Does not make

accurate 45 or

90 cuts

Stops not adjusted correctly

Angle pointer not set accurately

Miter gauge out of adjustment

Check blade with square and adjust

stops

Check blade with square and adjust

pointer

Adjust miter gauge

Material binds

blade when

ripping

Fence not aligned with blade

Warped wood

Excessive feed rate

Splitter not aligned with blade

Check and adjust fence

Select another piece of wood

Reduce feed rate

Align splitter with blade

Saw makes

unsatisfactory

cuts

Dull blade

Blade mounted backwards

Gum or pitch on blade

Incorrect blade for cut

Gum or pitch on table

Sharpen or replace blade

Turn blade around

Remove blade and clean

Change blade to correct type

Clean table

Blade does not

come up to

speed

Extension cord too light or to long

Low shop voltage

Motor not wired for correct voltage

Replace with adequate size cord

Contact your local electric company

Refer to motor junction box

Saw vibrates

excessively

Stand on uneven floor

Damaged saw blade

Bad V-belts

Bent pulley

Improper motor mounting

Loose hardware

Reposition on flat, level surface

Replace saw blade

Replace V-belts

Replace pulley

Check and adjust motor

Tighten hardware

Rip fence binds

on guide rails

Guide rails or extension wing not installed

correctly

Guide of rip fence not adjusted properly

Reassemble guide rails, refer to fence

manual

Adjust guides, refer to fence manual

Material kicked

back from blade

Rip fence out of alignment

Splitter not aligned with blade

Feeding stock without rip fence

Splitter not in place

Dull blade

Letting go of material before it is past

blade

Anti-kick back plates dull

Align rip fence with miter slot

Align splitter with blade

Install and use rip fence

Install and use splitter (with guard)

Replace blade

Push material all the way past blade

before releasing work

Replace or sharpen anti-kick back

plates

Blade does not

raise or tilt freely

Sawdust and debris in raising and tilting

mechanisms

Clean and regrease

Summary of Contents for MI-51350

Page 1: ...MODEL NO MI 51350 MI 51453 OPERATING MANUAL...

Page 8: ...8 G H J H C A...

Page 18: ...18 Table and Cabinet Assembly Flat FrontType...

Page 21: ...21 Motor and Trunnion Assembly Breakdown Left tilt...

Page 26: ...26 Blade Guard Assembly...

Page 28: ...28 Wiring Diagrams 3HP 230V 1Phase A1 A2...