Summary of Contents for MI-91600

Page 1: ...MODEL NO MI 91600 OPERATING MANUAL...

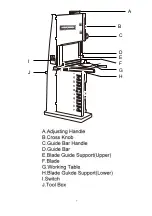

Page 8: ...7 A B C D E F G H J I...

Page 16: ...INSTALL 1 5 2 6 3 7 4 8 14...

Page 17: ...9 13 10 14 11 15 12 15...

Page 18: ...11 ADJUSTMENTS ADJUSTING KNOB TABLE 90 Shaft for 90...

Page 22: ......

Page 23: ...161...

Page 24: ...14...

Page 27: ......