-8-

the support bearing shafts. See Figure 8-3. Adjust

the shafts in or out so that the upper and lower

support bearings are within 1/64” of the back edge

of the blade. Retighten the screws.

For optimum support, the guide block assemblies

should be adjusted so they are just behind the

gullet line (the hollow points) of the blade. To

adjust the guide block assemblies, loosen the

screws securing the guide block yoke assemblies.

Move in or out in relation to the blade gullets.

Once adjusted, retighten the screw.

Now adjust the guide blocks. Loosen the guide

block screws and adjust each block so it is about

0.004” from the blade. This is about the same

thickness as a piece of typing paper. Retighten

the screws and turn the upper wheel by hand

through a complete revolution for the blade length

to ensure that the blade weld passes through the

guide blocks unhindered.

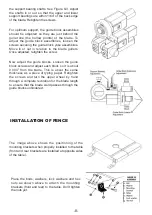

INSTALLATION OF FENCE

The image above shows the positioning of the

mounting brackets when properly installed to the table

(front and rear brackets are installed at opposite sides

of the table).

Place the bolts, washers, lock washers and hex

nuts as shown above to attach the mounting

brackets (front and rear) to the table. Don’t tighten

the nuts yet.

Summary of Contents for MI-92300

Page 1: ...MODEL NO MI 92300 OPERATING MANUAL START STOP ON OFF...

Page 15: ...14...

Page 17: ......

Page 20: ...FAULT DISPLAY...