12

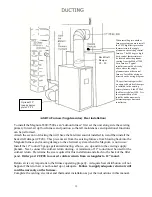

GUIDELINES FOR EXHAUST VENTING SYSTEMS DESIGN, CONT……

1)

Determine the “equivalent pipe length” for each component used according to the comparison chart

below. Add the “equivalent pipe length” of all components to get the “total equivalent pipe length”.

2)

Determine the altitude at which you are installing the stove.

3)

Cross-reference the “total equivalent pipe length” and the altitude using the graph below.

NOTE:

The “total equivalent pipe length” should not exceed 30-35 feet.

Component

Equivalent Length

Equivalent Pipe Length

Horizontal Straight Pipe

Actual Length in ft. x 1.0

Horizontal Pipe

=

1 x (2+1) =

3 ft.

Vertical Straight Pipe

Actual Length in ft. x 0.5

Vertical Pipe

=

0.5 x 8 =

4 ft.

90

0

Elbow or Tee

5.0 feet

90 Degree Tee

=

2 x 5 =

10 ft.

45

0

Elbow

3.0 feet

45 Degree Tee

=

1 x 3 =

3 ft.

TOTAL

=

20 ft.

NOTE: These are guidelines only. Proper venting is accomplished by design and common sense. In most

installations 4 inch diameter venting is required. It is the responsibility of the installer to determine proper

venting operation of the furnace. If the proper venting and combustion air balancing is not achieved, the

furnace will burn dirty, have a tendency to have the fire go out inconsistently and will cause the unit to plug

up the heat exchangers and back areas of the appliance. If the heat exchangers and back heat exchangers

are plugged and it causes the tubes to burn through or the heat exchanger to break, this is not covered under

warranty.

0 2 4 6 8 10 12

ALTITUDE X 1,000 FEET

25

20

15

10

5

0

4” DIAMETER ONLY

3” OR 4” DIAMETER

CRITERIA FOR SELECTING PIPE DIAMETER

MAXIMUM

0 2 4 6 8 10 12