28

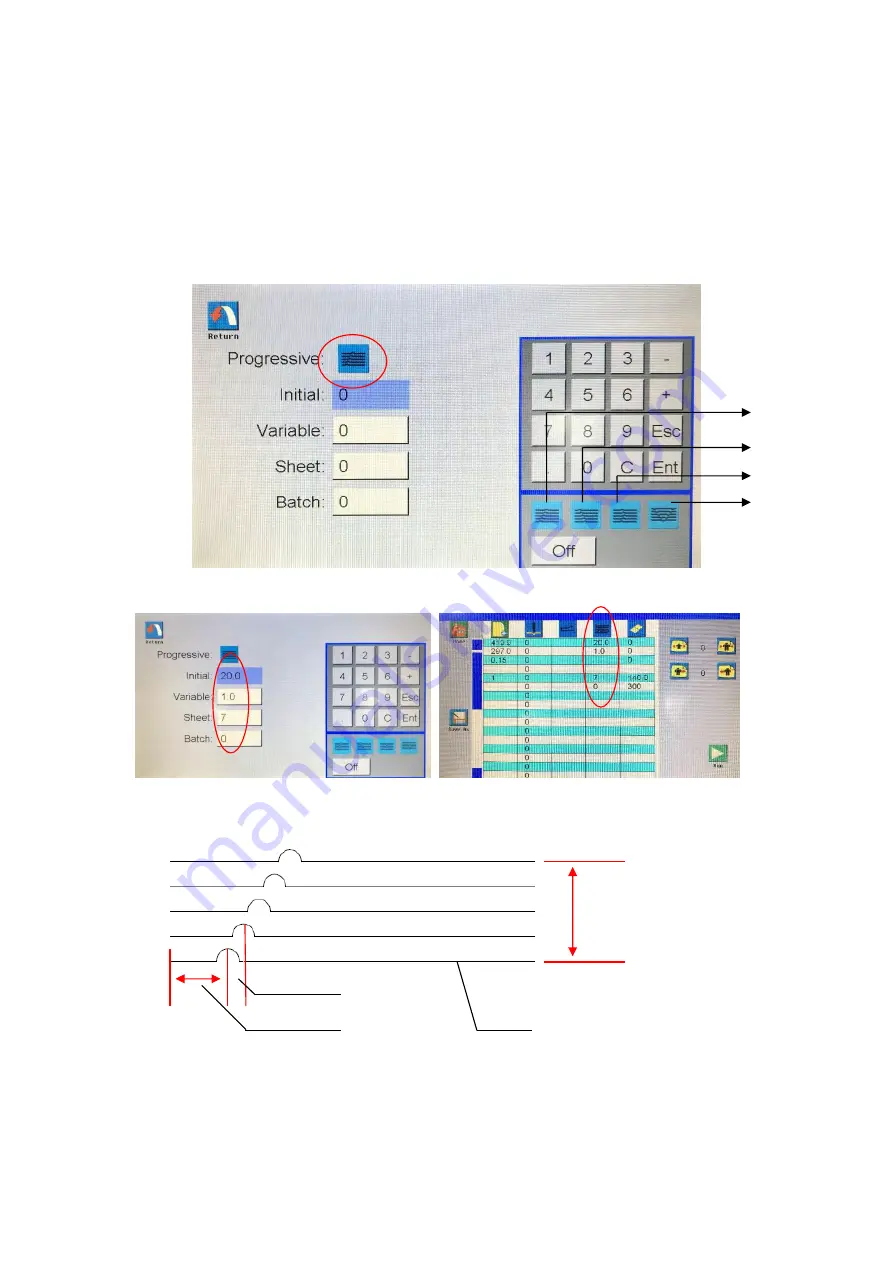

5.8.1 Progressive increase

Choose the progressive increase (#1 in figure 1), it will appear next to the

“progressive” (figure 1’s red circle). Then, input the relative data, for example,

initial: 20, variable: 1.0, sheet: 7, Batch: 0 (figure 2). Next, return to data

preview screen. The data will show up (figure 3).

Progressive increase concept diagram

:

According to above diagram, the initial means the first sheet’s crease data.

Variable means the different between two sheet’s crease lines.

Sheets

Initial

Variable

First sheet

①

②

③

1

3

2

4