Operation

Revision 001

4-5

Model TE100

Electronic Small Bagging Scale

b. There are two dials, each scaled from 0% to 100%. The right dial is the over control and

the left dial is the under control.

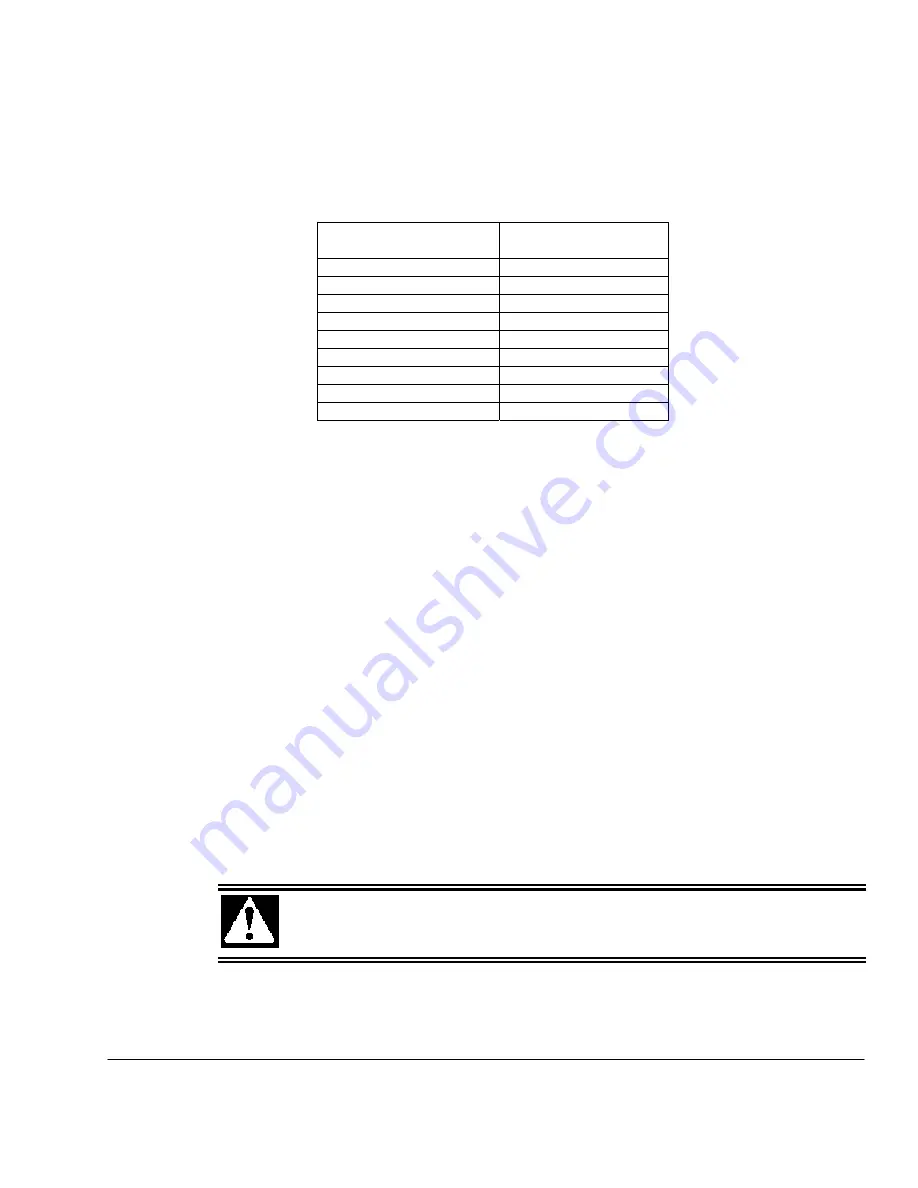

c. Zero to full scale is an 0.8 pound swing. Refer to the table below for the dial settings to

achieve 0.1-pound increments.

Table 4-2.

Over/Under Reject Dial Settings (0 to 100 = 0.8 Lbs)

Dial Setting (%)

Allowable Over/Under

Weight (Lbs)

0 0.0

12 0.1

25 0.2

37 0.3

50 0.4

67 0.5

75 0.6

87 0.7

100 0.8

d. Turn each dial to select the desired over/under setpoints. The settings selected will

depend on how much overweight and underweight is acceptable. For example, if the

Target Weight is 50 pounds. With the over reject set at 50% and the under reject is set at

25%, the TE100 will accept bags that weigh from 49.8 to 50.4 pounds.

15. Adjust the dribble gate. The dribble gate controls the amount of product flowing through the

TE100. If the TE100 is filling a 50 pound bag in less than 4 seconds and the bag weights are

erratic, close the dribble gate a little. This should restrict the flow and stabilize the bag weights.

If bag weights are very stable and fill times are slow, open the dribble gate to reduce fill time.

Try different adjustments of the dribble gate until you find the optimum combination of

minimum fill times with acceptable bag weight stability. Refer to 7.2.3 Dribble Gate

Adjustments.

16. Setup of the unit is now complete. The unit should be ready to be placed in normal operation.

Important: Once the TE100 is setup, do not shut it off. If the power is turned off, the TE100 will

lose its memory and when power is restored, the TE100 will have to go through the auto

correction process again. This machine consumes minimal power.

4.4 Normal Operation (Typical Fill Cycle)

Once the unit has been properly set up, normal operation will consist of the following steps:

1. Place a bag on the spout.

WARNING

Be sure to keep fingers and loose clothing away from bag clamps.

Failure to do so could result in personal injury.

2. Trip the rod on the start switch. The bag clamp jaws will close down on the bag clamp pads to

hold the bag in place. The shutoff gate will open to start the fill cycle.

3. When the bag nears the Target Weight, the dribble gate cylinder will extend, pushing the dribble

gate inward, thus slowing the flow of product into the bag.

Summary of Contents for TE100

Page 1: ...Taylor Products Model TE100 Electronic Small Bagging Scale Operation and Maintenance Manual ...

Page 6: ...Model TE100 Electronic Small Bagging Scale iv Revision 001 This Page Intentionally Left Blank ...

Page 86: ......

Page 88: ......

Page 90: ......

Page 91: ...Machine Type TE100 Dwg Name ISO 4 dwg Dwg View Scale Cabinet Exploded View ...

Page 92: ......

Page 95: ...Machine Type TE100 Dwg Name ECT146ASY dwg Dwg View Controller Circuit Board ...