Repair

Model TE100

Electronic Small Bagging Scale

7-4 Revision

001

7.3 System Repairs

Over time, components on the TE100 may become worn or damaged. If this occurs, follow the

procedures in this section to repair or replace individual components.

WARNING

When replacing parts, it is critical that only parts approved by Taylor

Products are used.

7.3.1 Spout Replacement

If the spout becomes damaged or worn, use the procedures below to replace it.

7.3.1.1 Spout Removal

1. Turn the TE100 off.

2. Disconnect the main electrical and pneumatic connections.

3. Label and disconnect the air supply lines that are connected to the bag clamp cylinders.

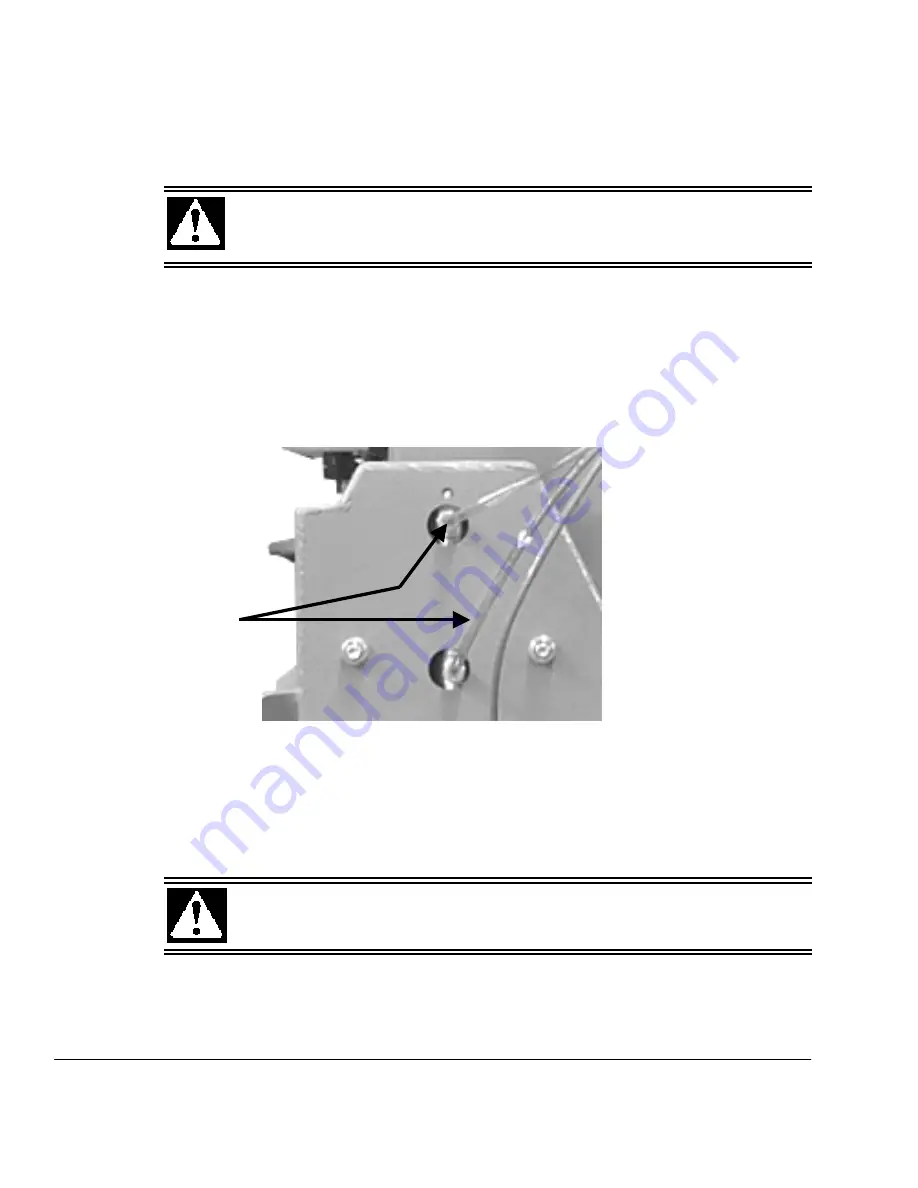

Table 7-1.

Bag Clamp Cylinder Air Supply Lines (1 Side Shown)

4. Remove the bag clamp actuator switch.

5. Remove the start switch.

6. Remove the two spout mounting bolts.

7. Remove the spout by lifting it up slightly, and sliding it toward the rear of the TE100, then

lowering it until it clears the load cell

CAUTION

A sudden jerk or shock, such as being struck by a tool or hitting the

spout, etc., can cause load cell damage. The load cell is NOT

covered by warranty.

8. Lower the spout until it clears the scale cabinet. Set the spout assembly aside.

Note: If the spout is being replaced, follow the procedures in this chapter to transfer the

components that are mounted to the spout over to the new spout.

Bag clamp cylinder

air supply lines (1

side shown)

Summary of Contents for TE100

Page 1: ...Taylor Products Model TE100 Electronic Small Bagging Scale Operation and Maintenance Manual ...

Page 6: ...Model TE100 Electronic Small Bagging Scale iv Revision 001 This Page Intentionally Left Blank ...

Page 86: ......

Page 88: ......

Page 90: ......

Page 91: ...Machine Type TE100 Dwg Name ISO 4 dwg Dwg View Scale Cabinet Exploded View ...

Page 92: ......

Page 95: ...Machine Type TE100 Dwg Name ECT146ASY dwg Dwg View Controller Circuit Board ...