BREAK-IN PROCEDURE

Note: The XL .25ARNV thru .36ARNV are ABC engines. The cylin-

der sleeve is tapered at the top, causing severe resistance when the piston

moves through the top of the stroke. This is normal. When the engine

heats up to operating temperature, this resistance will decrease and the

proper clearance will be achieved. The break-in procedure will guide you

through the steps necessary to properly break-in your new ABC engine.

Please follow the steps closely.

The break-in process allows the engine parts to perfectly fit to each

other and properly protect each part from premature wear. The engine

should be broken in using a fuel that contains no more than 10% nitro

methane and no less than 20% Castor Oil lubricant. Synthetic lubricant

fuels should not be used during the break-in procedure. For the break-in

procedure we recommend mounting the engine into the airplane it will be

used in. This way the muffler, fuel tank and throttle linkage can all be

tested in combination with the engine. If your airplane uses a cowling, it

should be removed during the break-in procedure.

q

1)

Turn the high speed needle valve out 2-1/2 turns from the fully

closed position.

STARTING PROCEDURE

The XL .25ARNV thru .36ARNV can be started using an electric starter or

they can be started by hand. For safety and ease of starting, especially

when the engine is new, we recommend using an electric starter. The fol-

lowing two procedures should be done with the power to the glow plug off.

q

Starting with an Electric Starter

When using an electric starter it is not necessary to prime the engine. The

starter turns the engine over fast enough that the engine draws fuel on it’s

own. Priming the engine prior to using an electric starter can cause the

engine to “hydro-lock” or flood. This is a result of too much fuel in the

engine before it actually fires. Turning the engine over with an electric

starter while the engine is flooded can cause extreme damage to the engine

and/or cause your propeller assembly to come loose. Turn the propeller

through the compression stroke one time by hand to check for a hydro-

locked state before applying the starter.

q

Starting by Hand

When starting the engine by hand always use a chicken stick. Never just use

your hand or serious injury could result. To make the engine easier to start

by hand it should be primed. This is done by opening the carburetor com-

pletely and choking the engine by putting your finger over the carburetor

opening. With the carburetor choked, “pull” the propeller through the com-

pression stroke 2 - 3 times. This will draw fuel into the engine. Remove

your finger and pull the propeller through the compression stroke once to

check for a hydro-locked condition.

PROPELLER, FUEL & GLOW PLUG

q

Propeller Recommendation

The diameter and pitch of the propeller needed for the XL .25ARNV thru

.36ARNV will vary greatly depending on the application the engine is used

in. The weight, drag and the type of model and how you intend to fly it are

all factors in determining the correct size propeller to use. Experimenta-

tion will be necessary to find the optimal size propeller for your particular

application. Ideally you want a propeller that the engine will turn in the

10,000 - 14,000 R.P.M. range, yet power the airplane sufficiently. Using a

propeller that is too small will cause the engine to run at too high an R.P.M.

Using a propeller that is too large will cause the engine run at too low an

R.P.M. and cause it to lug down too much. In both instances this can lead

to premature engine wear and eventual failure.

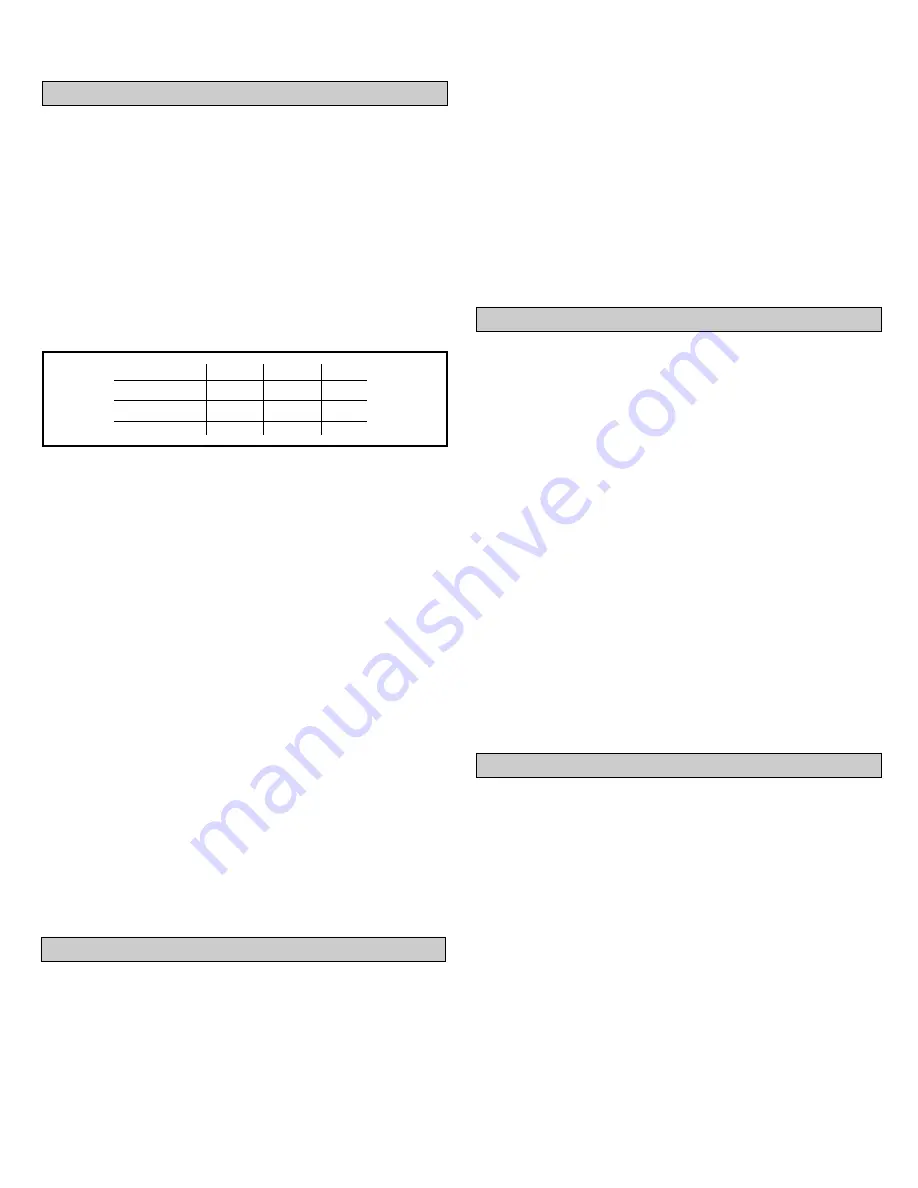

Propeller Size Recommendations

q

Glow Plug Recommendation

Glow plugs can also make a big difference on the performance of your

engine. For the XL .25ARNV thru the .36ARNV we recommend using a

hot heat range glow plug intended specifically for two cycle engines. Do

not use a cold heat range plug. This can lead to erratic engine runs and

eventual engine wear and failure.

q

Fuel Recommendation

Fuel can make a big difference in the way your engine performs. We rec-

ommend using two types of fuel with the XL .25ARNV thru .36ARNV

engines. For the break-in period you must use a fuel containing no more

than 10% nitro methane and no less than 20% Castor Oil lubricant. Use of

fuel containing more than the recommended percentage of nitro methane

or any synthetic lubricants will cause the engine to run too hot and result in

excessive wear and engine failure in a very short period of time. Once the

engine has been adequately broken in (about 1/2 gallon of the recommended

break-in fuel), a fuel containing up to, but no more than 15% nitro methane

and no less than 16% Castor Oil and synthetic lubricant blended fuel can

be used.

Note: We do not recommend using fuels that contain only synthetic

lubricants. Synthetic lubricants have a much lower flash point than Cas-

tor Oil lubricants. Flash point is the point at which the lubricant begins to

actually burn and loses it’s lubricating qualities. Using fuels containing a

blend of Castor Oil and synthetic lubricants results in an engine that runs

cooler and lasts longer. One lean run using a fuel containing only syn-

thetic lubricants can cause engine failure. Using fuels with a Castor Oil

and synthetic blend of lubricants greatly reduces this chance.

HIGH & LOW SPEED NEEDLE VALVES

q

High Speed Needle Valve

The high speed needle valve is used to meter the air/fuel mixture at full

throttle. Turn the needle clockwise to lean the mixture or turn the needle

counterclockwise to richen the mixture. When you start the engine for the

very first time the needle valve should be turned in completely, then backed

out 2-1/2 turns. When you start the engine after that, leave the needle

valve in the same position it was in when you shut down the engine.

q

Low Speed Needle Valve

The low speed needle valve regulates the air/fuel mixture at idle and dur-

ing transition from idle to full throttle. Turn the idle mixture screw clock-

wise to lean the mixture. Turn it counterclockwise to richen the mixture.

The idle mixture screw is preset from the factory, but minor adjustments

may need to be made. To reset the mixture screw to the factory setting

open the carburetor barrel completely. While holding the barrel open, for

the XL .25ARNV and .28ARNV turn the mixture screw in until it stops.

From this point, turn the mixture screw out 3 turns. For the XL .32ARNV

and .36ARNV turn the mixture screw out until it stops. From this point,

turn the mixture screw in 3 turns. These are the factory settings for each

engine. These adjustments should be made with the carburetor barrel held

firmly open.

XL .25ARNV

9 x 5

9 x 6

XL .28ARNV

9 x 5

9 x 6

9 x 7

XL .32ARNV

9 x 6

9 x 7

10 x 5

XL .36ARNV

9 x 7

10 x 5

10 x 6