Maguire Products, Inc.

Edition: May 27, 2009 – VBD-50

13

VBD

- Vacuum Batch Dryer

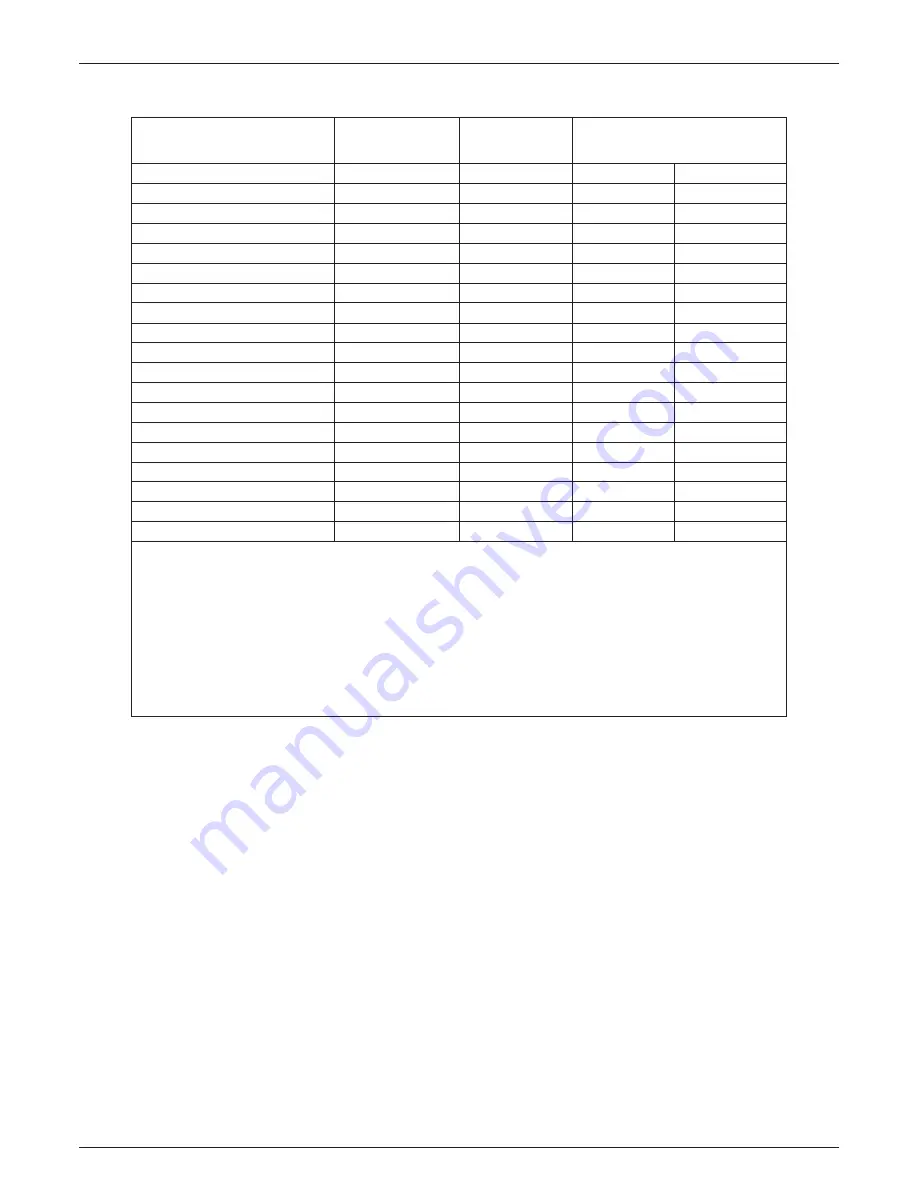

3.3 – Recommended Heat Times and Temperatures

MATERIAL

FINAL

MOISTURE % *

HEAT TIME

(MINUTES)**

DRYING TEMPERATURE***

ºC ºF

ABS

0.10

30 - 35

80 - 85

180 – 190

ABS/PC

0.02

35 - 40

100

210

LCP

0.02

30 - 60

150

300

PA

0.20 - 0.10

30 - 40

80 - 85

180 – 190

PBT

0.02

30 - 35

120

250

PC

0.02

30 - 35

125

250

PC/PBT

0.02

30 - 35

125

250

PEEK

0.20 - 0.10

35 - 40

150

300

PEI

0.02

30 - 50

150

300

PES

0.05 - 0.02

35 - 40

150

300

PET (Molding Grade)

0.010

30 - 45

150

300

PET (Preform, Extrusion)

0.005

30 - 45

150

300

PMMA (Acrylic)

0.02 - 0.04

40

85

185

POM (Acetal)

0.20 - 0.10

45

80 - 110

180 – 230

PPO

0.02

45

100 - 120

210 – 250

PPS

0.02 45

150

300

PUR

0.02

45

125 - 140

260 – 280

PSU

0.02

35 - 40

150

300

SAN

0.20 - 0.10

30 - 50

80

180

* Final moisture content as recommended by the raw material manufacturer.

** Recommended heat time is based on average initial moisture content. For high initial

moisture content cycle time should be extended 5 minutes. When in doubt contact Maguire

Service.

*** Drying temperature as recommended by the material manufacturer.

Drying is accomplished when all material reaches the proper temperature, and is then

placed under sufficient vacuum for a sufficient period of time.

Measurement of moisture content of material, both prior to and after drying, is

accomplished by using a moisture analyzer such as one manufactured by Arizona

Instruments.

Summary of Contents for VBD-50

Page 2: ...Maguire Products Inc Edition May 27 2009 VBD 50 2 VBD Vacuum Batch Dryer...

Page 14: ...Maguire Products Inc Edition May 27 2009 VBD 50 14 VBD Vacuum Batch Dryer 3 4 Dryer Overview...

Page 36: ...Maguire Products Inc Edition May 27 2009 VBD 50 36 VBD Vacuum Batch Dryer 6 3 VBD 50 Diagrams...

Page 37: ...Maguire Products Inc Edition May 27 2009 VBD 50 37 VBD Vacuum Batch Dryer...

Page 38: ...Maguire Products Inc Edition May 27 2009 VBD 50 38 VBD Vacuum Batch Dryer...