VL-VLP IM 19 JUNE 2017 © 2017 NOVATEC, Inc. All Rights Reserved

Page 10

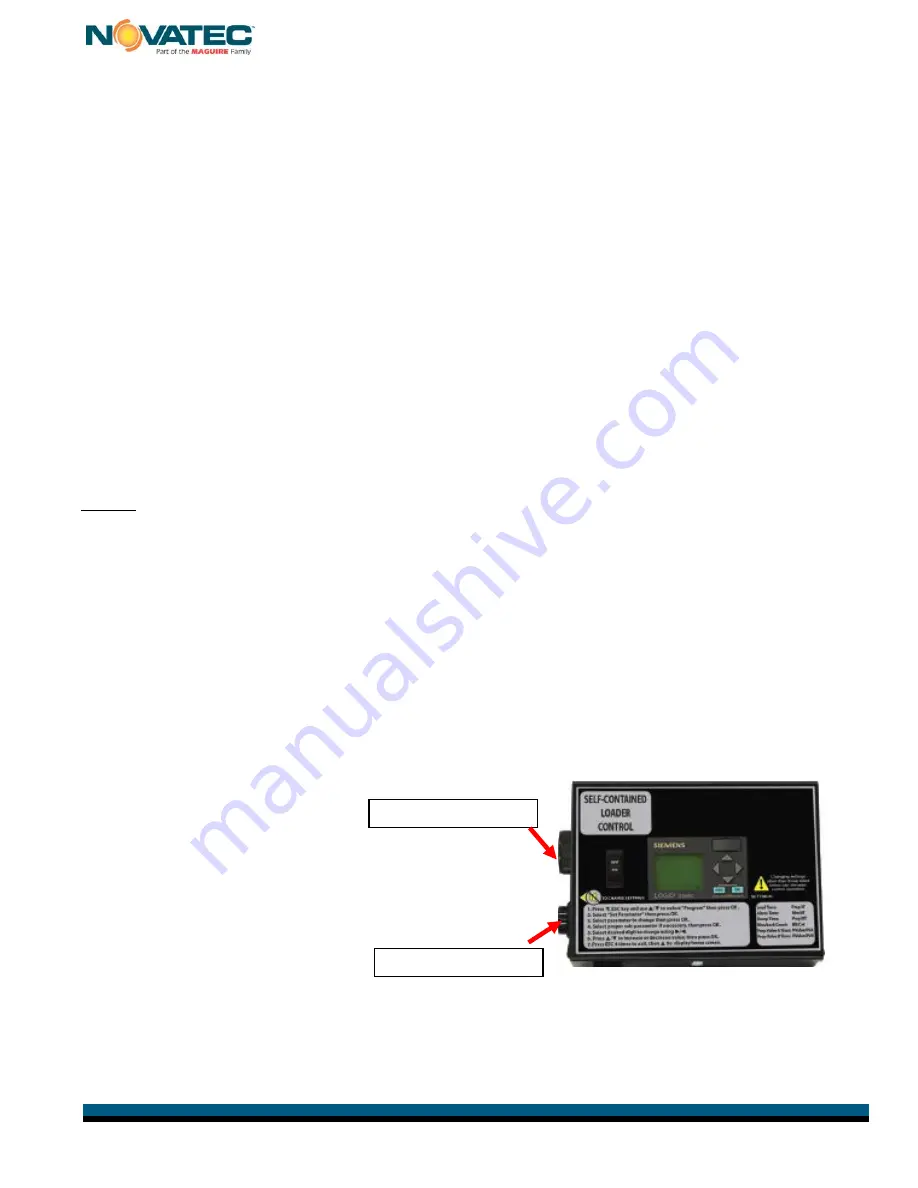

No-Load Alarm Horn

Alarm Horn Silencer

6-

OPERATION OVERVIEW

Pressing the OFF/ON switch will start the vacuum motor, creating vacuum suction through

the conveying line, to the pick-up wand and the loader will load material into the loader’s

vacuum chamber for an adjustable length of time.

When the load time is completed, the vacuum motor will stop, allowing material in the

vacuum chamber to relax and flow through the dump valve to the hopper or machine below.

Simultaneously, the filter will be cleaned with pulses of compressed air blown down through

the filter media. The dump time and the number of pulses used to clean the filter are

adjustable.

Load and dump/pulse cycles will continue until the drying hopper, surge bin or machine

hopper below the loader is full, at which time loaded material will either hold the dump valve

flapper open or trigger a sensor, placing the system in a holding mode. As material is

consumed by the process and flows from the hopper below the loader, the material level will

fall, the flapper will close or sensor will be uncovered, and the loader will begin to load

automatically again, to keep the hopper full.

NOTE: Once the vacuum motor starts, a loading cycle will continue through the load, dump,

and pulse cycles, even if the dump flapper is held open. The loader control senses a full

condition only after the completion of the dump/pulse cycle.

7-

NO-LOAD ALARM FEATURE

The No-Load alarm feature monitors the dump flapper on hopper mounted units, to assure it

opens as it should by material discharging after loading. If the flapper does not open 3

seconds after the dump sequence has started, the no load alarm on the side of the control

will sound. On machine mounted units, the No-Load alarm monitors the photo-eye demand

sensor on the glass base to determine if loaded material interrupts the sensor path.

The alarm horn can be silenced with the silence pushbutton on the side of the control.

8-

ADJUSTING the LOADER CONTROL

The VL and VLP series loaders

from NOVATEC employ a

Siemens brand, model LOGO!

Mini-PLC Control for loading functions. The control is

housed in a rugged enclosure and is factory programmed

for functions related to vacuum loading.

NOTE: The user may adjust certain parameters of the

control to fine tune their loader’s

operation, but changing settings

other than those listed can

damage control operation.

The control is equipped with a small LCD screen that displays operating and programming

prompts, plus pushbuttons to aid in selecting parameters and making changes. A No-Load

alarm horn is located on the side of the enclosure along with a silence button.

Instructions listed here are repeated on the control face for ease of use.