VL-VLP IM 19 JUNE 2017 © 2017 NOVATEC, Inc. All Rights Reserved

Page 5

3-

VL SPECIFICATIONS

NOVATEC VL Series vacuum loaders are completely automatic self-cleaning vacuum

loaders designed to convey virgin pellets and regrind materials from storage containers to

drying hoppers or directly to process machines.

Machine Mount Models with a sight glass are available as standards for all VL and VLP

models.

Each unit is shipped complete with all controls for immediate operation, and include a

hardware package. The hardware package includes 15 feet of flexible vacuum hose, hose

clamps and a material pick up lance.

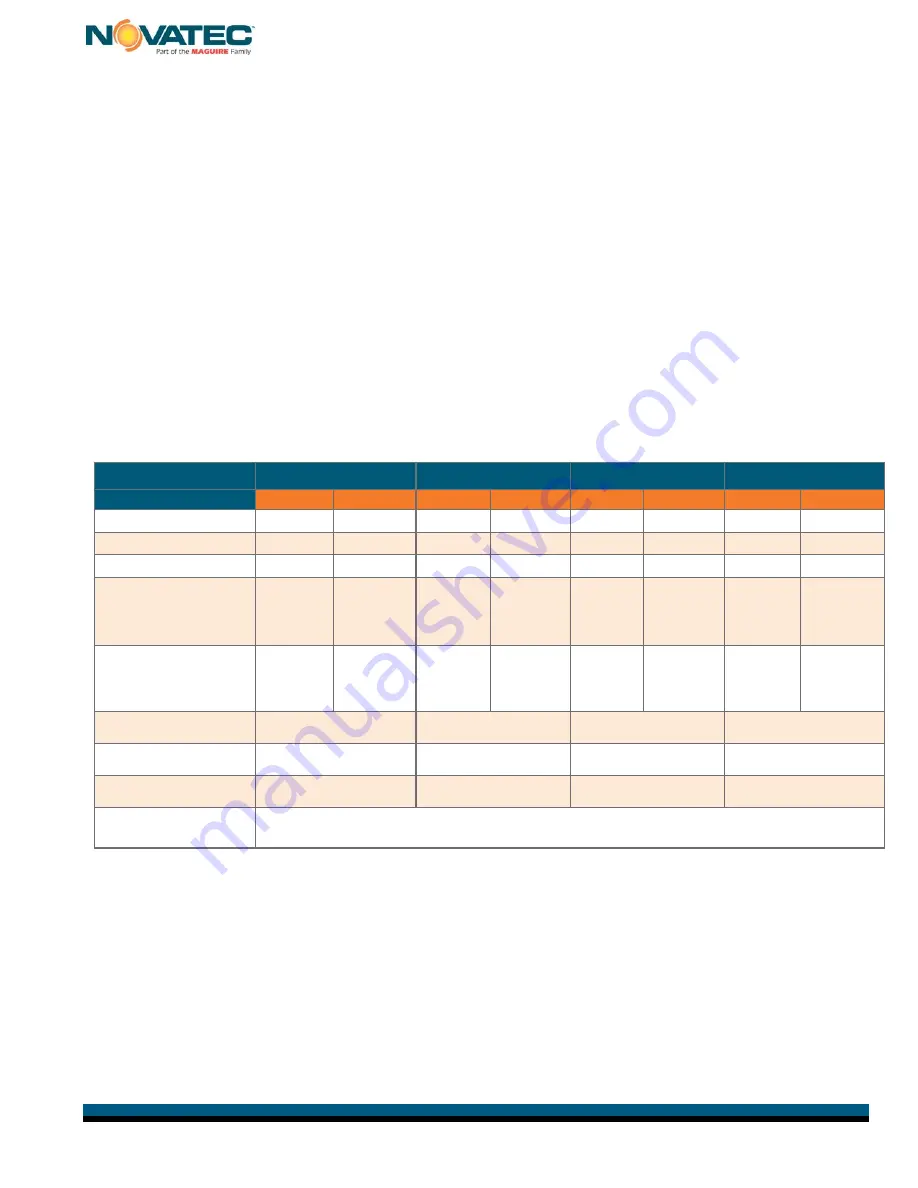

Model

VL-5 / VL-5-MM

VL-12 / VL-12-MM

VL-19 / VL-19-MM

VL-38 / VL-38-MM

Characteristic

U.S.

Metric

U.S.

Metric

U.S.

Metric

U.S.

Metric

Volume

1/25 ft

3

1.1 liters

1/3 ft

3

9 liters

1/2 ft

3

14 liters

1.0 ft

3

28 liters

*Resin Capacity

1.5 lb

0.7 Kg

12 lb

6 Kg

19 lb

9 Kg

38 lb

17 Kg

Inlet/Dump Throat OD

1.5/2 in

38/50 mm

1.5/2 in

38/50 mm

2 / 2 in

50/50 mm

2.25/5 in

57/127 mm

**Recommended

Throughput / hr

(Brush Type Motor)

200 lb

91 Kg

400 lb

181 Kg

500 lb

227 Kg

650 lb

295 Kg

**Recommended

Throughput / hr

(Brushless Motor)

N/A

N/A

650 lb

295 Kg

1000 lb

454 Kg

1200 lb

544 Kg

Load Time: (seconds)

up to 99

up to 99

up to 99

up to 99

Dump Time: (seconds)

up to 99

up to 99

up to 99

up to 99

Amps @115V

8

13

13

13

Compressed Air Usage

.2 CFM (5.66 liters/min)

All Models

* Resin capacity and throughput based on 38 lb/ft

3

bulk density. Adding external proportioning valve reduces throughput.

** Recommended throughput/hr based on free flowing virgin pellets through 15’ of flex hose. Exceeding recommended

throughputs may result in shortened brush and filter life however, increased throughputs are possible depending on resin

and equivalent feet calculation. Generally, a central conveying system should be used for higher throughputs.

Maximum conveying distance in addition to 15’ flex hose, can include 30’ of horizontal tubing and 1 elbow. Additional

vertical travel, bends or flex hose will reduce recommended throughput.