w w w . m a g u r a . c o m

s e r v i c e @ m a g u r a . d e

The filling and bleeding of a MAGURA brake is not a routine work. This is due

to the fact that the MAGURA Royal Blood hydraulic oil does not absorb water like

DOT brake liquid in cars and on motorcycles. A filling and bleeding of a MAGURA

is therefore only necessary in case of an incorrect installation or a tubing change

after this has been damaged. Only use MAGURA Royal Blood hydraulic oil, never

DOT brake liquid!

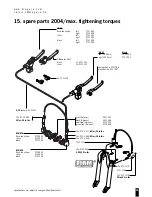

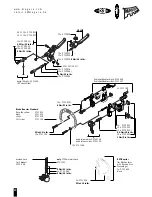

1.

The service kit contains everything you need which you need for bleeding or repai-

ring your MAGURA brake.

2.

Push (by hand) a barbed fitting into

both

the transparent filler and vent tubes.

3.

Put the filler tube on the syringe and fill

completely

with MAGURA BLOOD mineral

oil. In the case of an emergency, cooking oil will work, but needs to be flushed out after

the return to civilization.

Never use DOT brake liquid! Pay close attention not to

have any air in the tube or syringe.

Remove bleed screw (5mm allen screw) at the

slave cylinder. Fit filled syringe and filler tube and

fix it

with an 8mm open end wrench.

4.

Turn the brake lever (HS 33/11) horizontal on the handlebar so that the bleed

bolt is at the highest position. Turn back

fully

the TPA knob or allen adjustment bolt in

the brake lever. Remove the bleed screw in the brake lever.

5.

Install the vent tube and hold its end into the oil bottle.

6.

Push the oil through the system.

Use the whole content of the syringe.

You can

see air in the form of small bubbles in the vent tube.The bleed is completed when no more

air bubbles can be seen in the vent tube.Remove the vent tube and replace the bleed

screw.

(Tightening torque 4Nm/34 in.lbs).

Remove syringe from slave cylinder and

replace the bleed screw.

(Tightening torque 4Nm/34 in.lbs).

Return brake lever to its

normal riding position, and clamp correctly.

(Tightening torque 4Nm/34 in.lbs).

They system is correctly bled when the pads move immediately upon

activating the lever-blade. Adjust the pad/rim clearance with the TPA or the

allen adjustment bolts (see chapter maintenance/pad change). Check the entire

system for oil leaks. Check the flawless performance, high power and excellent

modulation.

11. Filling and bleeding

14