51

BA023001-en

•

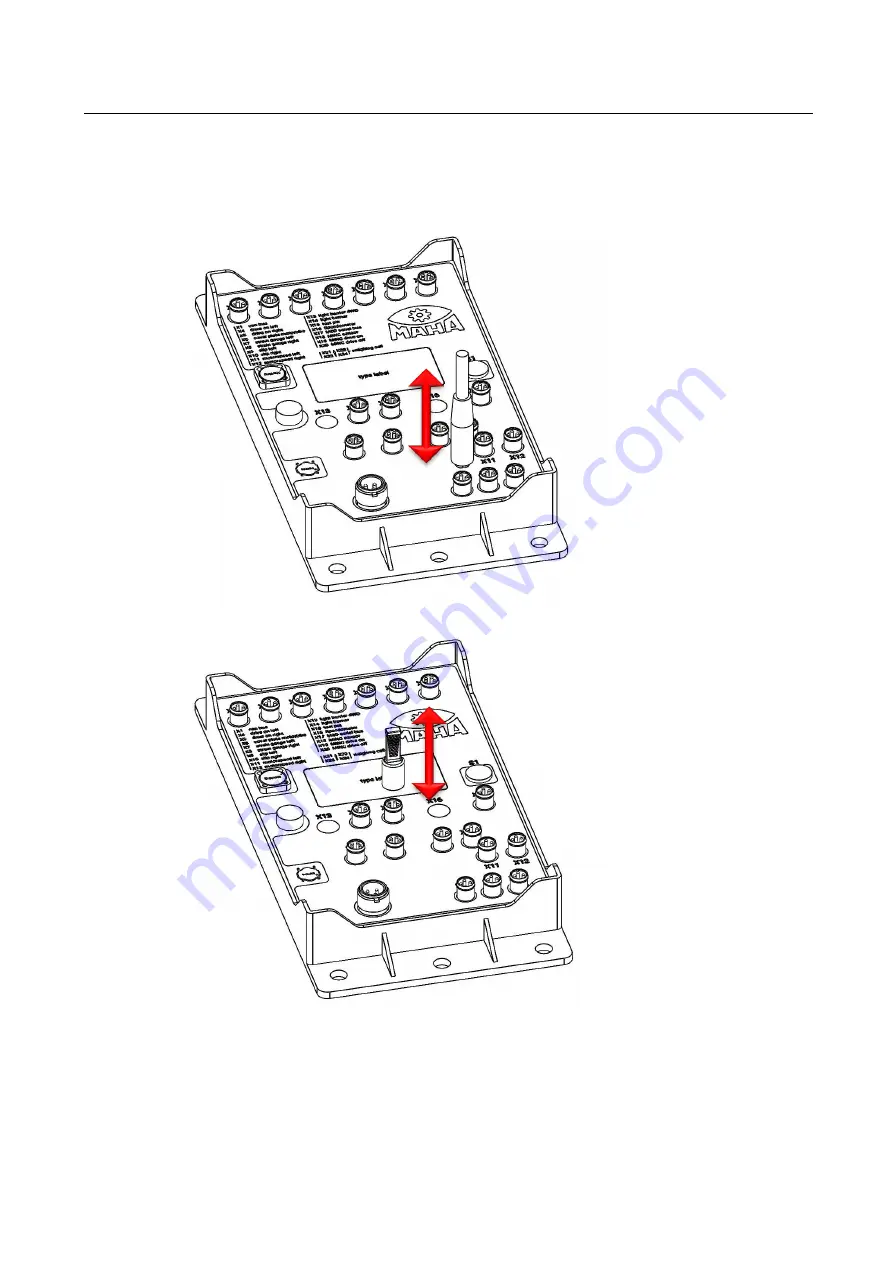

M8 sensor connector mounting/dismounting on IFM

Mount by carefully inserting the 3/4-pin connector. It is locked by lightly snapping into

place when plugged in. The connector must not be turned under pressure!

•

M8 protective cap mounting/dismounting on IFM

Unused plug-in connections must be fitted with a black rubber protective cap. If

necessary, remove these by pulling gently.

Summary of Contents for CONNECT Series

Page 19: ...19 BA023001 en 2 3 2 Set up diagram Set up diagram I ...

Page 20: ...20 BA023001 en Set up diagram II ...

Page 22: ...22 BA023001 en 2 4 1 Wiring diagram ...

Page 23: ...23 BA023001 en 2 4 2 Control cabinet structure Basic variant ...

Page 24: ...24 BA023001 en 2 4 3 Control cabinet structure Full equipment ...

Page 25: ...25 BA023001 en ...

Page 53: ...53 BA023001 en ...

Page 138: ...138 BA023001 en 13 Annex 13 1 Naming convention ...